Processing method and processing device of crylic acid and ester heavy components

A technology of acrylates and treatment methods, which is applied in chemical instruments and methods, preparation of carboxylic acid esters/lactones, separation/purification of carboxylic acid compounds, etc., and can solve problems such as waste of resources, high treatment costs, and incomplete recovery , to achieve high recovery rate, long-term stable operation, high economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

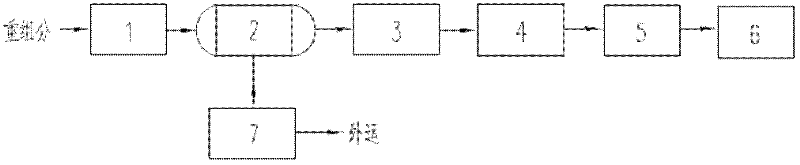

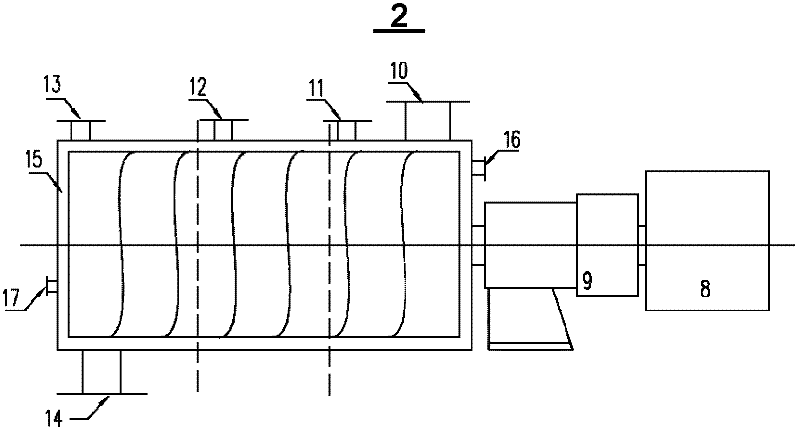

Method used

Image

Examples

Embodiment 1

[0044] The heavy component of acrylic acid comes from an acrylic acid production enterprise. The sample is a black viscous liquid with a large viscosity coefficient and a certain pungent smell. It is collected and placed in storage tank 1. Send 1000g of acrylic acid heavy fraction into the spiral cracking furnace 2, raise the temperature to 140-160°C, distill and crack for 5 hours, cool it through the condensation system 3 and enter the fraction collector 4, the concentration of acrylic acid in the fraction is measured by gas chromatography-mass spectrometry, and the acrylic acid is calculated Purity is 98%, enters in the recycling pool 6 after being purified into high-purity acrylic acid through rectifying tower 5 then (purification is high-purity acrylic acid 673g, acrylic acid recovery rate is 99%), the residue after the distillation cracking enters residue collector 7. The whole process does not need to add any solvent, the process is simple, the recovery rate is high, and ...

Embodiment 2

[0052] The heavy component of butyl acrylate comes from an acrylic acid production enterprise. The sample is a black liquid with a certain pungent smell. Send 1000g of butyl acrylate heavy fraction into the spiral cracking furnace, raise the temperature to 170-225°C, distill and crack for 3 hours, cool it through the condensing system and enter the fraction collector, the concentration of acrylic acid in the fraction is measured by gas chromatography-mass chromatography, and the purity of acrylic acid is calculated 79%, and then purified into 559g of high-purity acrylic acid through a rectification tower, the recovery rate of acrylic acid is 99%, and the residue after distillation and cracking enters the residue collector. The whole process does not need to add any solvent, the process is simple, the recovery rate is high, and it has high economic and social benefits.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com