Manufacturing method for automobile sign capable of realizing radar active cruise function

A technology for automobile signs and manufacturing methods, applied to vehicle parts, devices for coating liquid on the surface, ion implantation plating, etc., can solve the problem that microwave radar cannot smoothly transmit and receive radio waves, and cannot accurately measure the distance between front, rear, left, and right vehicles, Hinder the normal emission of microwave radar waves, etc., to achieve the effect of beautiful appearance, high hardness and strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

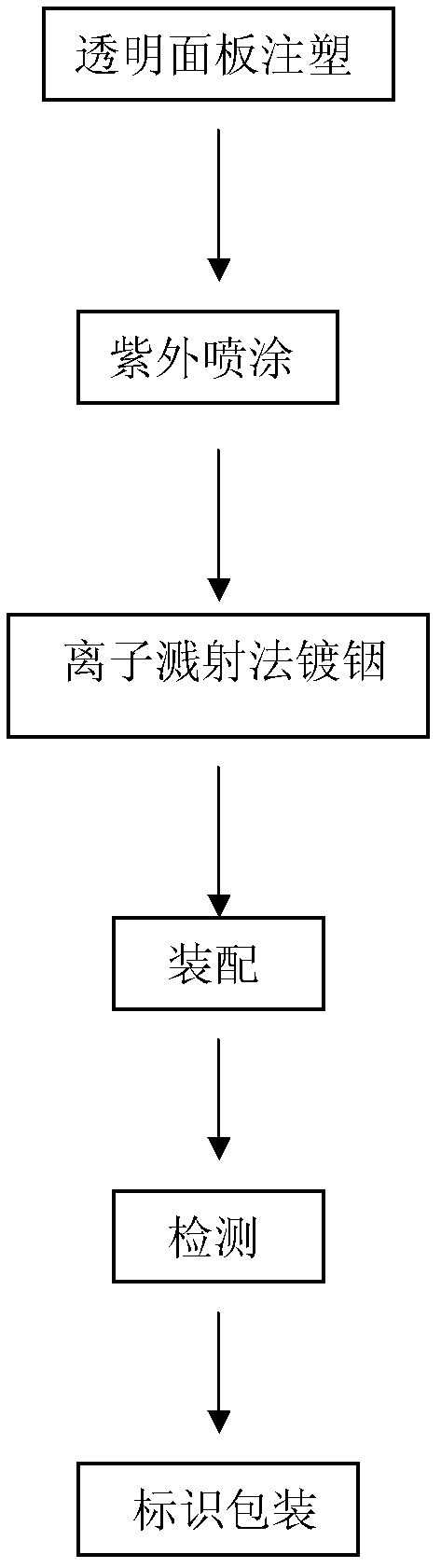

[0020] The present invention is a kind of manufacture method of the automobile label that can satisfy the radar active cruise function, such as figure 1 shown, including the following steps:

[0021] (1) Injection molding: Use an injection molding machine to make transparent polycarbonate plastic into a curved panel with a thickness of 5mm to obtain a transparent plastic sign;

[0022] (2) UV spray paint: place the transparent plastic signage obtained in step (1) in automatic UV (ultraviolet light curing) coating equipment, the caliber of the spray gun of the automatic UV coating equipment is 0.8mm, and the spray gun The width is 5cm, the air pressure of the spray gun is 3bar, and the opening of the spray gun is 10cm away from the transparent plastic sign. Spray the UV-curable paint with metal powder evenly on both sides of the transparent plastic sign, and then the paint is leveled for 8 minutes, and then the transparent plastic sign Rotate 360 degrees around the ultraviol...

Embodiment 2

[0028] The present invention is a kind of manufacture method of the automobile label that can satisfy the radar active cruise function, such as figure 1 The following steps are shown:

[0029] (1) Injection molding: use an injection molding machine to make transparent polycarbonate plastic into a curved panel with a thickness of 6mm to obtain a transparent plastic sign;

[0030] (2) UV spray paint: place the transparent plastic signage obtained in step (1) in automatic UV coating equipment. The diameter of the spray gun of the automatic UV coating equipment is 0.6mm, and the spray width of the spray gun is 8cm. The air pressure of the spray gun is 4bar, and the opening of the spray gun is 15cm away from the transparent plastic sign. Spray the UV-curable paint with metal powder evenly on both sides of the transparent plastic sign, and then the paint is leveled for 10 minutes, and then the transparent plastic sign is 360 degrees around the UV light source. Rotate and control th...

Embodiment 3

[0036] The present invention is a kind of manufacture method of the automobile label that can satisfy the radar active cruise function, such as figure 1 The following steps are shown:

[0037] (1) Injection molding: Use an injection molding machine to make transparent polycarbonate plastic into a curved panel with a thickness of 5.5mm to obtain a transparent plastic sign;

[0038] (2) UV spray coating: the transparent plastic signboard obtained in step (1) is placed in automatic UV coating equipment, the caliber of the spray gun of the automatic UV coating equipment is 0.7mm, and the spray width of the spray gun is 6.5cm, The air pressure of the spray gun is 3-4bar, and the opening of the spray gun is 12cm away from the transparent plastic sign. Spray the UV-curable paint with metal powder evenly on both sides of the transparent plastic sign, then the paint is leveled for 9 minutes, and then the transparent plastic sign is wrapped around the UV The light source is rotated 360...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com