Silk fibroin multilayer functional membrane with gradient structure and its preparation method

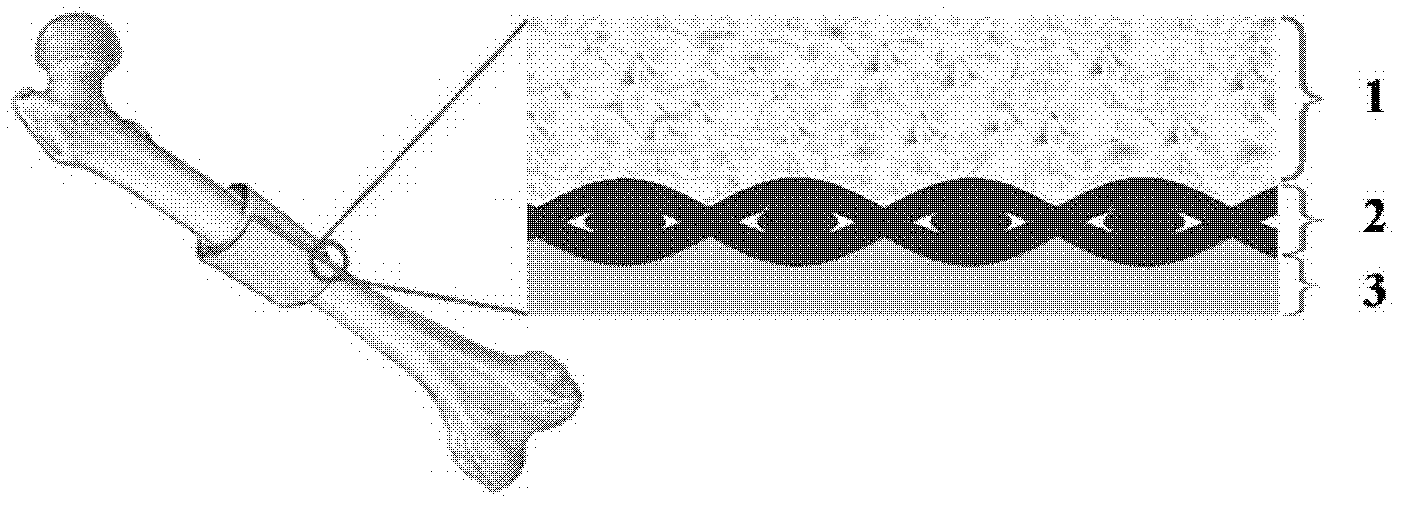

A silk fibroin, gradient structure technology, applied in the field of biomedical materials, to achieve the effect of accelerating bone regeneration rate, improving biological properties, and enhancing osteoconductive and osteoinductive capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

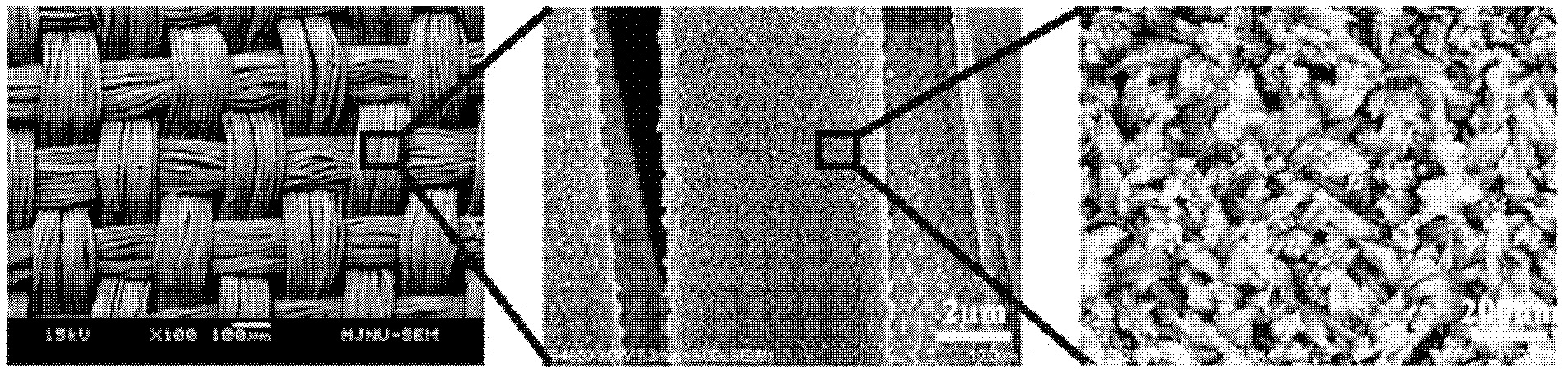

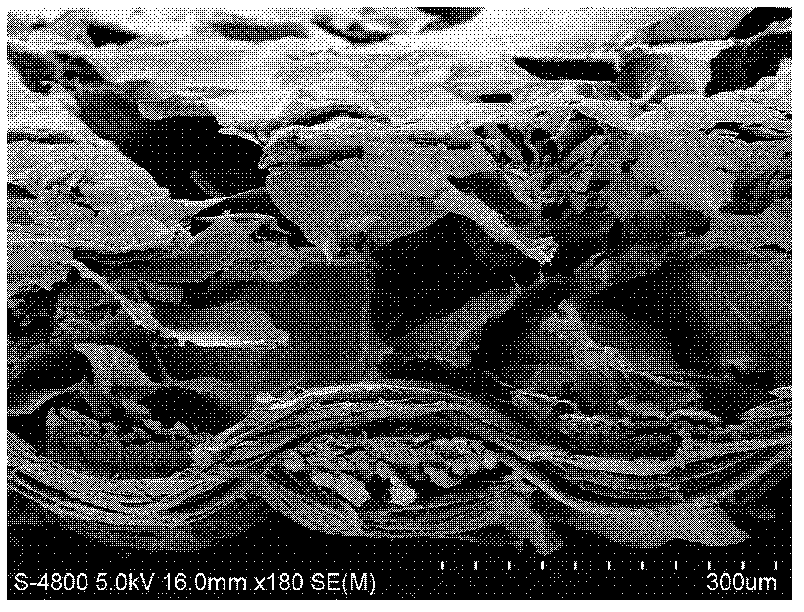

[0025] Take 0.05g of silk fibroin fabric, the concentration of immersion is 0.167mol L -1 , Soak it in the calcium source solution at 37°C for 0.5h, take it out, wash it twice with distilled water, and then immerse it at a concentration of 0.100mol L -1 in the phosphorus source solution for 0.5h. After repeated alternate dipping in this way for 6 times, the calcium phosphate-silk fibroin textile composite membrane (intermediate layer) was obtained after being washed with distilled water and ethanol for 3 times respectively, and dried at room temperature. from figure 2 In the SEM photo of the middle layer shown, it can be seen that calcium phosphate is deposited on the silk fibroin.

[0026] 0.3gPVP is added to the silk fibroin solution that 20ml concentration is 50g / L to form PVP-silk fibroin mixed solution (wherein the mass percentage of PVP and silk fibroin is 30%), this mixed solution is cast on the surface of the middle layer After drying at 10° C. to form a film, put ...

Embodiment 2

[0030] Take 0.10g of silk fibroin textile fabric, the concentration of immersion is 0.100mol L -1 , soaked in the calcium source solution at a temperature of 50°C for 2 hours, took it out, soaked it with distilled water for 3 times, and then immersed it in a concentration of 0.150mol L -1 , In the phosphorus source solution at a temperature of 50°C for 2h. Repeated alternate dipping in this way for 15 times, washed with distilled water and ethanol three times respectively, and dried at room temperature to obtain the calcium phosphate-silk fibroin textile composite membrane (middle layer).

[0031] 0.5g PEG is added to the silk fibroin solution that 20ml concentration is 100g / L to form PEG-silk fibroin mixed solution (the mass percentage of PEG and silk fibroin is 25%), and this mixed solution is cast on the surface of the middle layer After drying at 50° C. to form a film, put it into a vacuum drying oven to dry for 48 hours to obtain a double-layer film including an intermed...

Embodiment 3

[0035] Take 0.50g of silk fibroin textile fabric, the concentration of immersion is 0.800mol L -1 , Soak in calcium source solution at 20°C for 3 hours, take it out, soak it with distilled water for 3 times, and then immerse it in a concentration of 0.600mol L -1 , The temperature is 20 ℃ in the phosphorus source solution for 2h. After repeated alternate dipping in this way for 50 times, the calcium phosphate-silk fibroin textile composite membrane (intermediate layer) was obtained after being washed three times with distilled water and ethanol respectively, and then dried at room temperature.

[0036] 0.16g PVA is added to the silk fibroin solution that 20ml concentration is 80g / L to form PVA-silk fibroin mixed solution (the mass percentage of PEG and silk fibroin is 10%), and this mixed solution is cast on the surface of the middle layer After drying at 40° C. to form a film, it was placed in a vacuum drying oven for 64 hours to obtain a double-layer film containing an inte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com