Method for detecting epoxy equivalent weight

A detection method and epoxy equivalent technology, which can be used in material analysis by observing the influence of chemical indicators, and by chemical reaction of materials, etc., can solve the problem of unfavorable epoxy resin synthesis reaction termination point control, affecting turbidity. Point judgment, narrow application range and other problems, to achieve the effect of shortening the dissolution time, short detection time, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

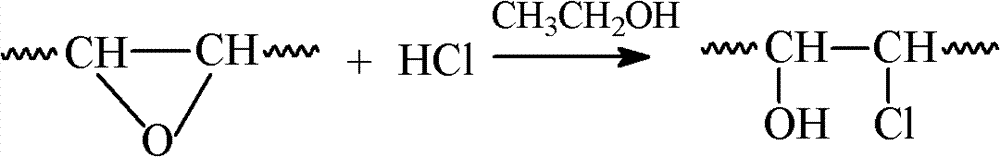

Method used

Image

Examples

Embodiment 1

[0061] 1. Pipette 300ml of butanone, 100ml of absolute ethanol and 20ml of hydrochloric acid and mix them into a brown volumetric flask to obtain a hydrochloric acid-ethanol-butanone solution for later use;

[0062] 2. Heat PEG300 in an oven at 105°C, measure 50ml of PEG300 solution at 100°C with a measuring cylinder, and pour it into a conical flask;

[0063] Weigh 0.5-2g of the compound containing epoxy groups into 50ml of hot PEG300, shake well and dissolve, then rinse the outer wall of the Erlenmeyer flask with cold water to cool;

[0064] 3. Add 4-6 drops of phenol red to the mixed solution obtained in step 2, pipette 20ml of hydrochloric acid-ethanol-butanone mixed solution into the sample to be tested, and shake for one minute;

[0065] Before titration, add 2ml of distilled water, titrate with 0.5mol / L NaOH standard solution, titrate until the solution is dark reddish brown, record the consumption volume of NaOH standard solution as V 1 ml;

[0066] 4. Add 4 to 6 dro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com