Method for preparing mixed regenerated polyester fibers special for non-woven material

A recycled polyester and non-woven technology, applied in stretch spinning, artificial filament heat treatment, single-component polyester artificial filament, etc., can solve the problems of low fiber strength, large elongation, and few developments of mixed fibers , to achieve excellent mixing effect, improve technical indicators, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

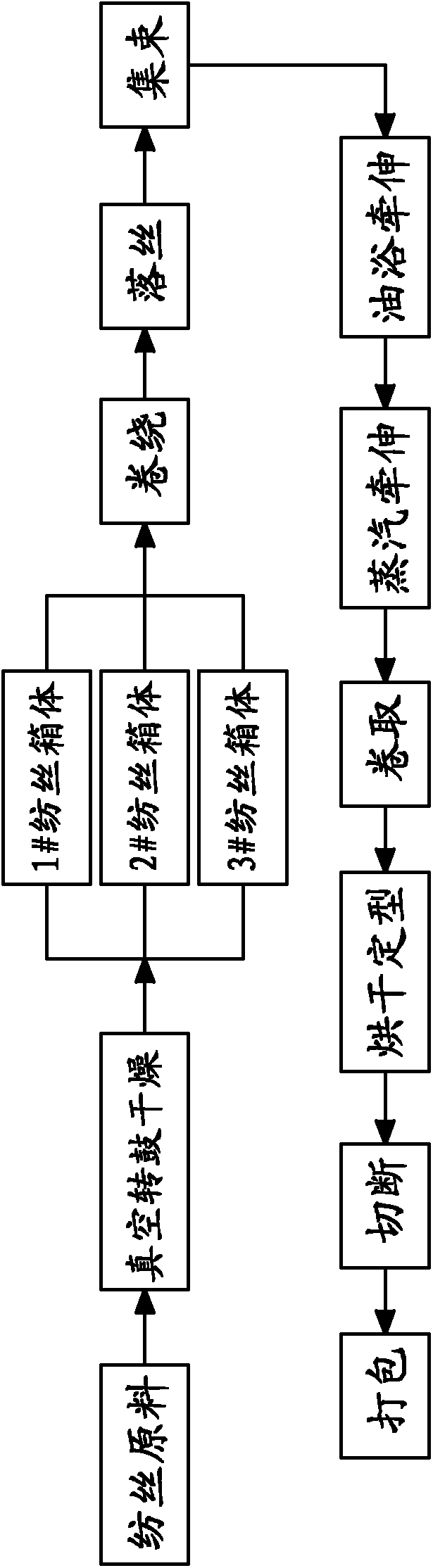

[0021] Such as figure 1 Shown, the preparation method of a kind of non-woven special mixed regenerated polyester fiber of the present invention, realize by following steps:

[0022] 1. 2399.52 kg of waste PET bottle flakes and 0.48 kg of fluorescent whitening agent are used as spinning raw materials; the melting point of waste PET bottle flakes is 256°C, the viscosity is 0.65dl / g, and the PVC content is 0.034%.

[0023] 2. Blend the above-mentioned spinning raw materials evenly and put them into a drum vacuum machine for drying. Set the vacuum degree of the drum vacuum machine to -0.098Mpa, set the steam pressure to 5.4kg, and set the drying temperature to 150°C. 10h, make the moisture content of waste PET bottle flakes be 132ppm.

[0024] 3. The above-mentioned dried spinning raw materials are fed into the screw extruder of the melt spinning equipment, and melt spinning is carried out through the spinning box of the melt spinning equipment. In this embodiment, two spinning ...

Embodiment 2

[0030] Such as figure 1 Shown, the preparation method of a kind of non-woven special mixed regenerated polyester fiber of the present invention, realize by following steps:

[0031] 1. 1919.52 kg of waste PET bottle flakes, 240 kg of chemical fiber friction material, 240 kg of foam material and 0.48 kg of fluorescent whitening agent are used as spinning raw materials. Among them, the melting point of waste PET bottle flakes is 256°C, the viscosity is 0.68dl / g, and the PVC content is 0.035%; the melting point of chemical fiber friction material is 250°C, the intrinsic viscosity is 0.55dl / g, and the PVC content is 0.034%; the melting point of foam material is 255℃, intrinsic viscosity is 0.62dl / g, PVC content is 0.036%;

[0032] 2. Blend the above-mentioned spinning raw materials and evenly add them to the drum vacuum machine for drying. Set the vacuum degree to -0.098Mpa, the steam pressure to 5.5kg, the drying temperature to 150°C, and dry for 10.5h, so that the waste PET Th...

Embodiment 3

[0039] Such as figure 2 Shown, the preparation method of a kind of non-woven special mixed regenerated polyester fiber of the present invention, realize by following steps:

[0040] 1. 1919.52 kg of waste PET bottle flakes, 480 kg of chemical fiber friction material or foam material and 0.48 kg of fluorescent whitening agent are used as raw materials for spinning; the melting point of waste and old PET bottle flakes is 254°C, the viscosity is 0.66dl / g, and the PVC content is 0.032%; the melting point of chemical fiber friction material is 250°C, the intrinsic viscosity is 0.55dl / g, and the PVC content is 0.034%; the melting point of foam material is 255°C, the intrinsic viscosity is 0.62dl / g, and the PVC content is 0.036%.

[0041] 2. Blend the above-mentioned spinning raw materials and evenly add them to the drum vacuum machine for drying. Set the vacuum degree to -0.098Mpa, the steam pressure to 5.6kg, the drying temperature to 150°C, and dry for 10.2 hours. It is 108ppm. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com