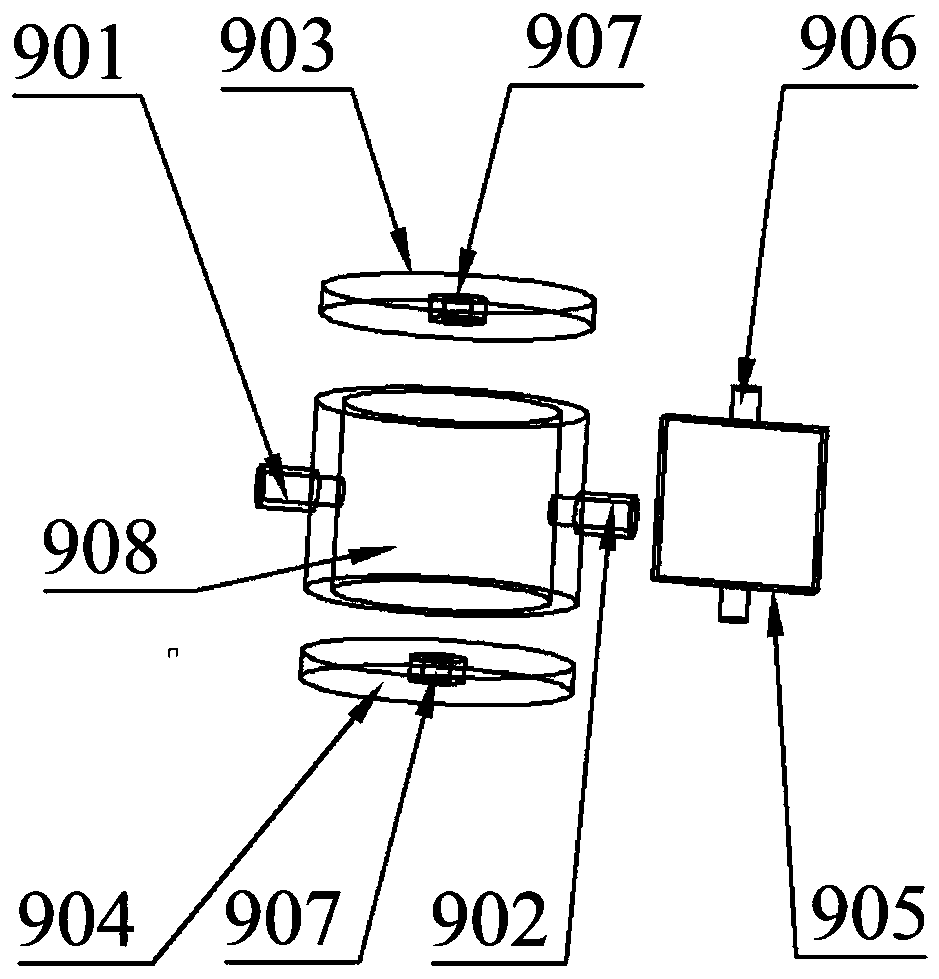

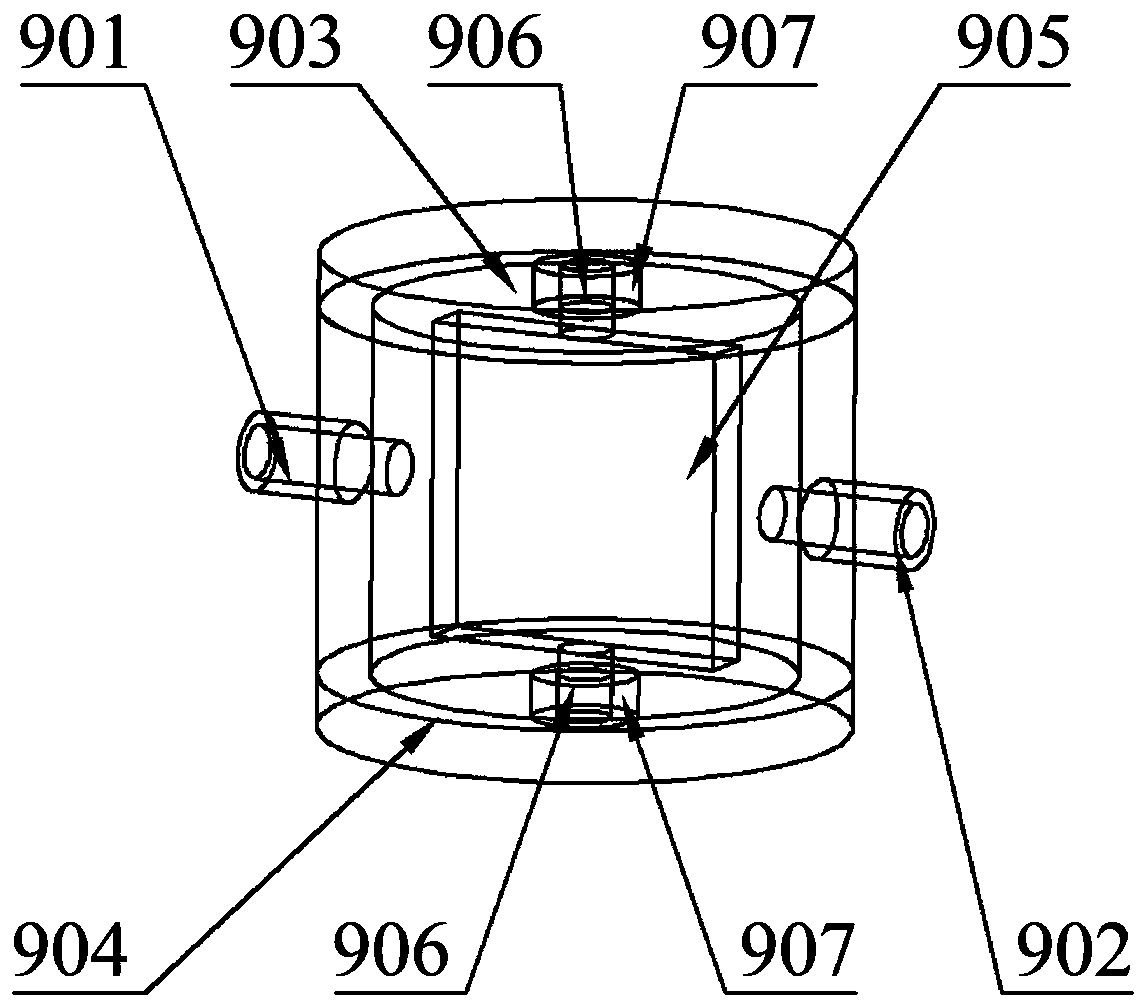

Test device and test method for oil-water relative permeability curve

A relative permeability and testing device technology, which is applied in the field of steady-state method oil-water relative permeability curve testing device, can solve the problem of long time for oil-water to reach a steady state, long time for saturation field stabilization, and large randomness of oil-water two-phase distribution And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] A method for testing oil-water relative permeability curves, comprising the steps of:

[0071] S1. Prepare simulated formation oil and simulated formation water, and put them into intermediate container I and intermediate container II after vacuumizing them respectively;

[0072] S2. Core preparation Take the drilling core for processing and drying, and measure the length L, diameter d, and dry weight m of the core 0 , gas porosity φ and gas permeability K, calculate the core cross-sectional area A and nitrogen method pore volume V pHe ,in,

[0073]

[0074] V pHe =Al×φ(2)

[0075] S3. After evacuating the core, it is saturated with simulated formation water, and then connected to the highly mixed steady-state oil-water relative permeability curve measurement experimental device and debugged to determine the effective pore volume V of the core. p and the calculation formula of core saturation S is:

[0076]

[0077]

[0078] Among them, m 0 is the core dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com