Preparation method of laponite (LAP)-doped polylactic acid-glycolic acid (PLGA) nanofiber

A technology of glycolic acid and nanofibers, which is applied in the fields of fiber chemical characteristics, spinning solution preparation, and medical preparations of non-active ingredients, etc., to achieve the effects of simple operation, easy product availability, and low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Take 4 parts of 0.8g PLGA, mix them with 2.4mL THF and 0.8mL DMF respectively, and stir at room temperature for 8h until PLGA is completely dissolved. 8mg, 24mg and 40mg of LAP powder were added to the 2nd, 3rd and 4th PLGA solution respectively. Magnetic stirring was used for 20 min at a stirring rate of 200 r / min to obtain PLGA and PLGA / LAP spinning solutions. PLGA, PLGA / 1%LAP, PLGA / 3%LAP and PLGA / 5%LAP nanofiber mats were prepared by electrospinning. Among them, the receiving distance is 15cm, the voltage is 20kV, and the flow rate is 0.8mL / h. The prepared composite nanofiber mat is dried in a vacuum oven for 48h to remove residual moisture and solvent.

[0051] SEM observation results show that the obtained PLGA, PLGA / 1% LAP, PLGA / 3% LAP and PLGA / 5% LAP nanofibers have regular morphology and regular surface, and the fiber diameters are 929±274nm, 617±178nm, 584±5nm, respectively. 167nm and 550±183nm (see attached figure 1 ). Comparing the diameters of four diffe...

Embodiment 2

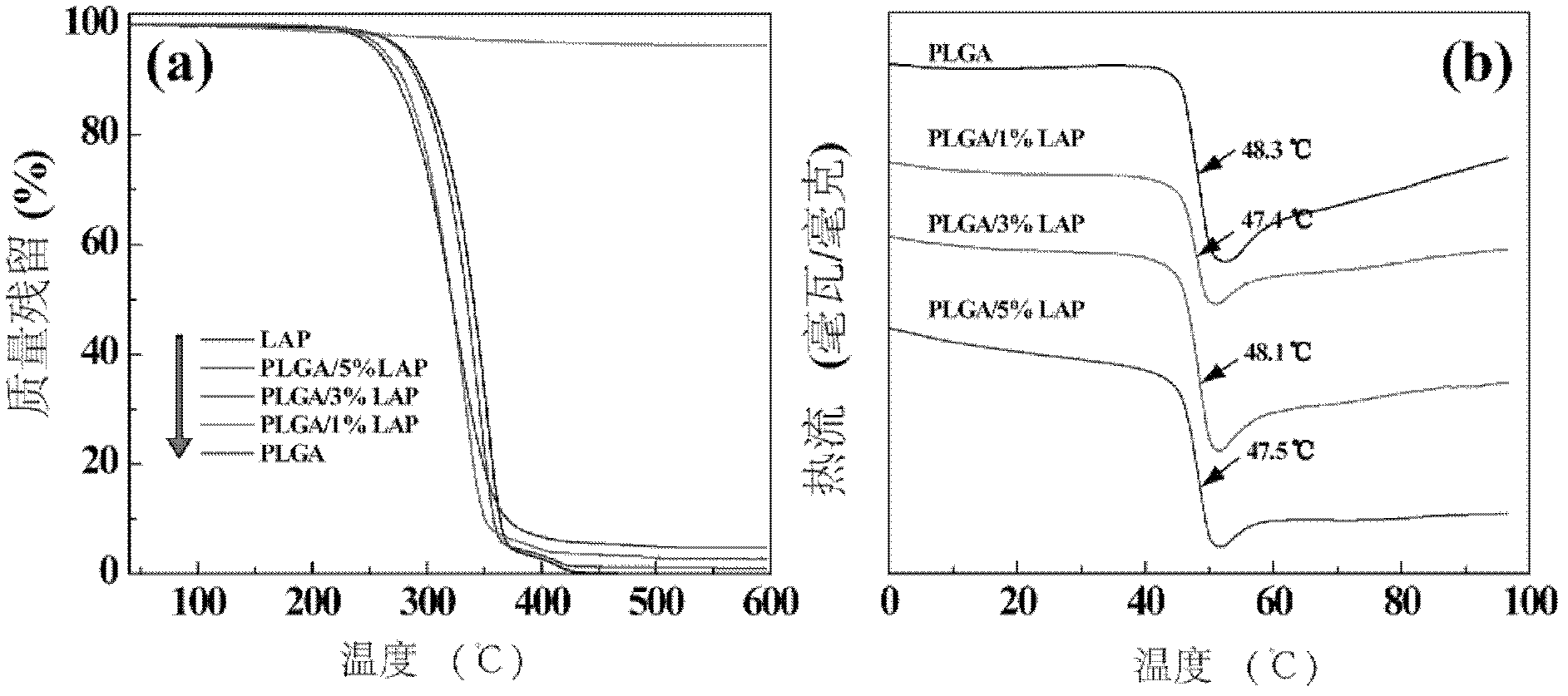

[0053] The PLGA, PLGA / 1%LAP, PLGA / 3%LAP and PLGA / 5%LAP nanofiber mats prepared in Example 1 of a certain mass (about 5mg) were weighed respectively for testing the thermodynamic properties of fiber materials (see attached figure 2 ). The thermodynamic performance test results show that when a certain amount of LAP nanoparticles is doped in the PLGA spinning solution, the melting point and glass transition temperature of the fiber mat decrease very little, indicating that LAP doped in the PLGA fiber will not be obvious Reduced thermal stability of PLGA nanofiber mats.

Embodiment 3

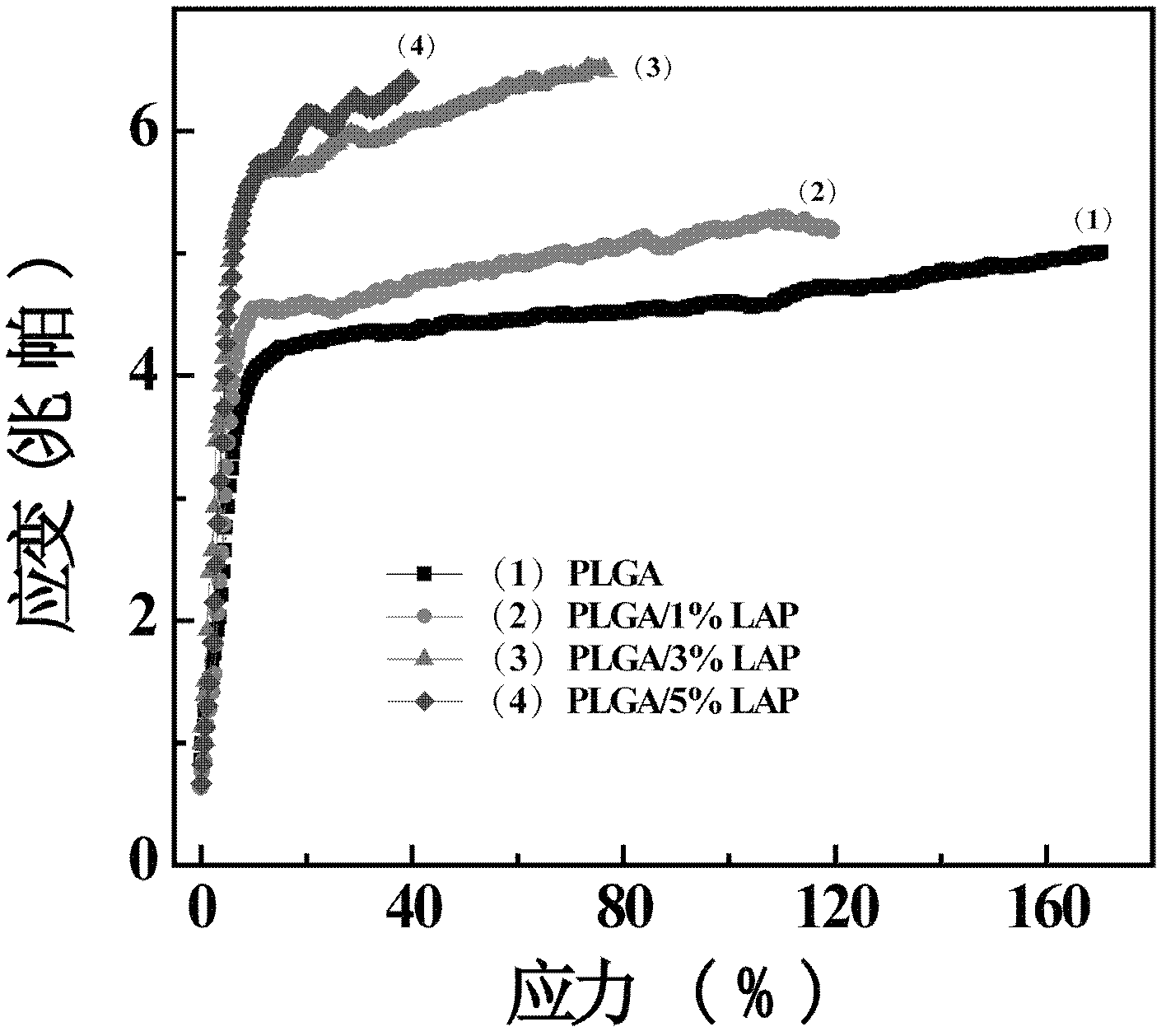

[0055] The PLGA, PLGA / 1% LAP, PLGA / 3% LAP and PLGA / 5% LAP nanofiber mats prepared in Example 1 were cut into strips of 1 cm×5 cm, and 3 parallel samples were taken for each sample. Measure the thickness of 3 different positions of each fiber mat with a micrometer, and calculate the average value as the thickness of each sample. Test the mechanical properties of the fiber mat with a universal material testing machine to obtain a stress-strain curve (see attached image 3 ). It can be seen from the stress-strain curve that the fracture strength of PLGA nanofibers can be significantly improved after a certain amount of LAP is doped in PLGA fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com