Production process and production system of durable PVB (polyvinyl butyral) intermediate films

A polyvinyl butyral and production system technology, applied in the production process and production system field of polyvinyl butyral interlayer film, can solve the problems of uneven thickness and poor durability of PVB film, and achieve production cost Low, uniform thickness, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

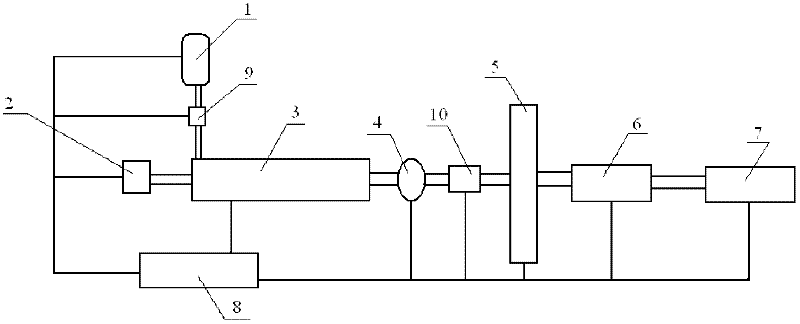

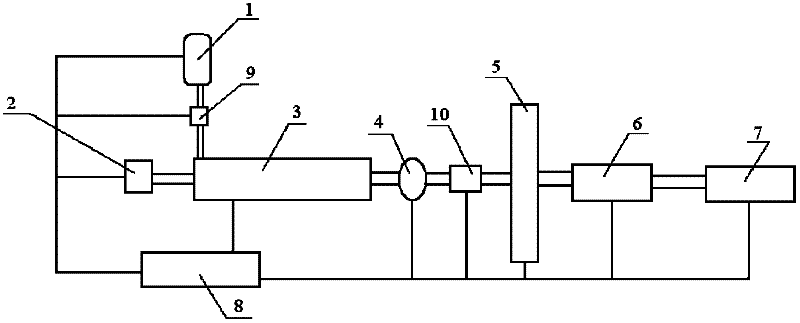

[0026] see figure 1 Shown:

[0027] The production process step of a kind of durable polyvinyl butyral PVB intermediate film of the present invention is as follows:

[0028] Step 1: Ingredients

[0029] Take 3.848kg of ultraviolet absorber, 1.924kg of anti-aging agent, and 0.928kg of antioxidant, add it to 253.3kg of plasticizer and heat it up to 60°C to let it fully dissolve, then cool down to 40°C to make a plasticizer liquid mixture and put it in the storage Stand-by in the liquid tank 1, wherein the ultraviolet absorber is UVP-327, and the composition is 2-(2'-hydroxyl-3', 5'-di-tert-phenyl)-5-chlorinated benzotriazole; anti-aging agent It is phosphite, molecular formula: C42H6303P; the antioxidant is antioxidant 1076, the name is octadecyl propionate, molecular formula: C35H6203; the plasticizer is triethylene glycol diisocaprylate, molecular formula: C22H4206;

[0030] Step Two: Extrude

[0031] (1), adding of the plasticizer liquid mixture: use the metering jet pump...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com