Method for preparing nano cationic spherical polyelectrolyte brush

A technology of polyelectrolyte brushes and cations, which is applied in the field of preparation of nano-cation spherical polyelectrolyte brushes, can solve problems such as difficulty in increasing graft density and easy formation of steric hindrance, and achieves simple and easy-to-operate methods, easy-to-control processes, and high graft density. The effect of branch density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

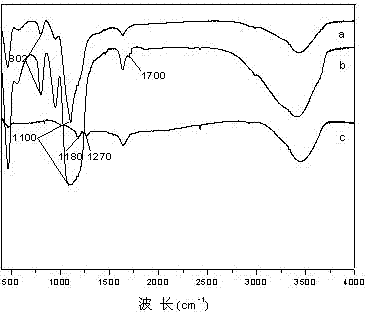

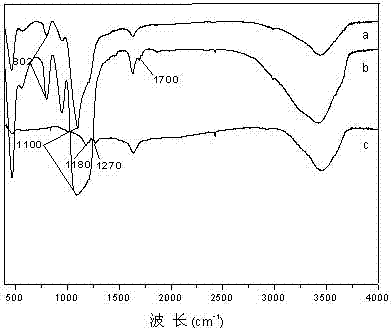

Image

Examples

Embodiment 1

[0029] Step 1, using the sol-gel method to prepare monodisperse nano-silica microspheres:

[0030] The preparation method of monodisperse nano-silica microspheres refers to the literature: Kota Sreenivasa Rao, et al. Journal of Colloid and Interface Science 2005; 289:125-131, and the obtained mass fraction is 4% nano-silica isopropanol Suspension, wherein the average particle size of silica microspheres is 100nm.

[0031] Step 2, preparing silica microspheres with unsaturated double bonds on the surface:

[0032] Add 40mg of γ-methacryloxypropyltrimethoxysilane (KH-570) to 100ml of alcohol-water mixture to obtain a reaction system. The volume ratio of alcohol and water in the alcohol-water mixture is 10:1, and the Adjust the pH of the reaction system to 4, and hydrolyze the obtained reaction system at room temperature for 1 hour; add 20 g of the nano-silica isopropanol suspension obtained in step 1 to the hydrolyzed reaction system, and reflux under the condition of a 70°C wa...

Embodiment 2

[0037] Step 1, using the sol-gel method to prepare monodisperse nano-silica microspheres:

[0038]The preparation method of monodisperse nano-silica microspheres refers to the literature: Kota Sreenivasa Rao, et al. Journal of Colloid and Interface Science 2005; 289:125-131, and the obtained mass fraction is 4% nano-silica isopropanol Suspension, wherein the average particle size of silica microspheres is 50nm.

[0039] Step 2, preparing silica microspheres with unsaturated double bonds on the surface:

[0040] Add 40mg of γ-methacryloxypropyltrimethoxysilane (KH-570) to 100ml of alcohol-water mixture to obtain a reaction system. The volume ratio of alcohol and water in the alcohol-water mixture is 3:1, and the Adjust the pH of the reaction system to 3, and hydrolyze the obtained reaction system at room temperature for 1 hour; add 20 g of the nano-silica isopropanol suspension obtained in step 1 to the hydrolyzed reaction system, and reflux under the condition of a water bath...

Embodiment 3

[0045] Step 1, using the sol-gel method to prepare monodisperse nano-silica microspheres:

[0046] The preparation method of monodisperse nano-silica microspheres refers to the literature: Kota Sreenivasa Rao, et al. Journal of Colloid and Interface Science 2005; 289:125-131, and the obtained mass fraction is 4% nano-silica isopropanol Suspension, wherein the average particle size of silica microspheres is 90nm.

[0047] Step 2, preparing silica microspheres with unsaturated double bonds on the surface:

[0048] Add 24mg of γ-methacryloxypropyltrimethoxysilane (KH-570) to 100ml of alcohol-water mixture to obtain a reaction system. The volume ratio of alcohol and water in the alcohol-water mixture is 10:1, and the Adjust the pH of the reaction system to 4, and hydrolyze the obtained reaction system at room temperature for 1 hour; add 20 g of the nano-silica isopropanol suspension obtained in step 1 to the hydrolyzed reaction system, and reflux under the condition of a 70°C wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com