High molecular solid-to-solid phase transition energy storage material and preparation method thereof

A solid-solid phase change and polymer technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of leakage of polymer solid-solid phase change material phase change enthalpy, solid-liquid phase change material leakage, etc. To achieve the effect of simple preparation process, easy to use in large quantities, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

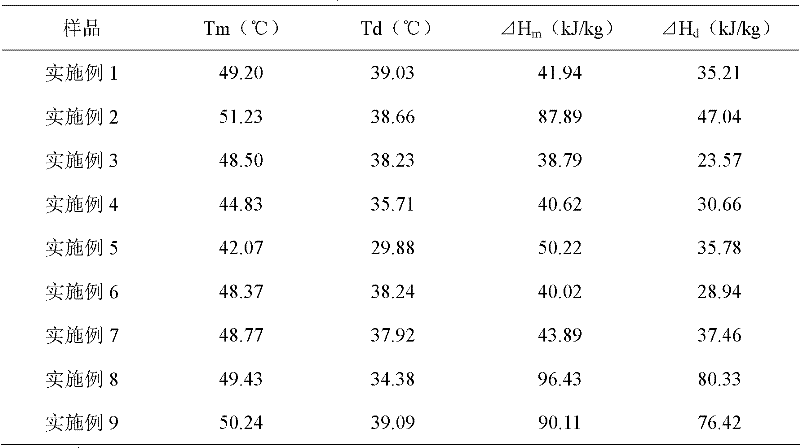

[0037] Add stearyl acrylate (SA) 16.23g (77.4%wt), methacrylic acid (MAA) 4.30g (20.5%wt) into the reactor equipped with condenser, dropping funnel, thermometer, and add 20mL toluene, The system was replaced with nitrogen, 4ml of 0.11g / ml BPO toluene solution (BPO 2%wt) was added dropwise, and the reaction was stopped after 10 hours at 55°C. The product was precipitated and washed with ethanol three times, and dried in an oven at 70°C for 5 hours. The samples were tested by differential scanning calorimeter (DSC) for phase transition enthalpy and phase transition temperature, and the data are listed in Table 1.

Embodiment 2

[0039] Add 6.49g (64.3%wt) of stearyl acrylate (SA) and 1.72g (17.0%wt) of methacrylic acid (MAA) into a reactor equipped with a condenser tube, dropping funnel, and thermometer, and add 10mL of toluene, The system was replaced with nitrogen, 4ml of 0.025g / ml BPO toluene solution (BPO 1%wt) was added dropwise, reacted at 70°C for 6h, and then 1.79g of N,N-dimethylethanolamine (DMEA) (17.7% wt), stirred at 25-30°C for 6h, the product was precipitated with ethanol and washed three times and dried. The samples were tested by differential scanning calorimeter (DSC) for phase transition enthalpy and phase transition temperature, and the data are listed in Table 1.

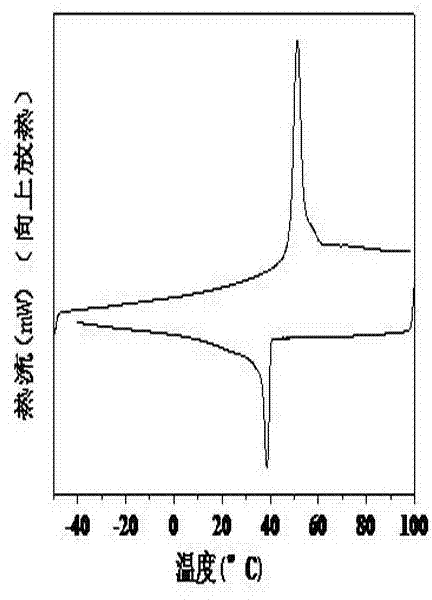

[0040] from figure 1 It can be seen that the heating and cooling curves have peaks at 51.23°C and 38.66°C, indicating that the phase change temperature and phase change enthalpy are reversible, that is, there are both melting peaks and crystallization peaks, and the phase change enthalpy of the phase change material H...

Embodiment 3

[0042] Add 15.62g of methacrylate-β hydroxyethyl ester and 28.45g of stearic acid (methacrylic acid-β hydroxyethyl stearate accounts for 85.0%wt) into a condenser tube, dropping funnel, thermometer, and water separator Add 0.53g of catalyst methanesulfonic acid and 40mL of toluene to the reactor, reflux and dehydrate at 110-140°C until the amount of dehydration is close to the theoretical value, then add 7.21g (14.5%wt) of acrylic acid, replace the system with nitrogen, drop Add 5ml of 0.05g / ml BPO toluene solution (BPO 0.5%wt), stop the reaction after reacting at 85°C for 5h, the product is washed three times with ethanol and dried in an oven at 70°C for 5h to obtain a polymer material with phase change function (The phase-change monomer accounts for 85.0%wt of the total monomer amount). The samples were tested by differential scanning calorimeter (DSC) for phase transition enthalpy and phase transition temperature, and the data are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com