Castable for ladle deslagging plate, and preparation method and applicable of castable

A castable and slag plate technology, applied in the field of refractory materials, can solve the problems of affecting production speed, increasing production cost, shortening melting loss, etc., to prolong service life, improve high temperature resistance and impact resistance, and be easy to control Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

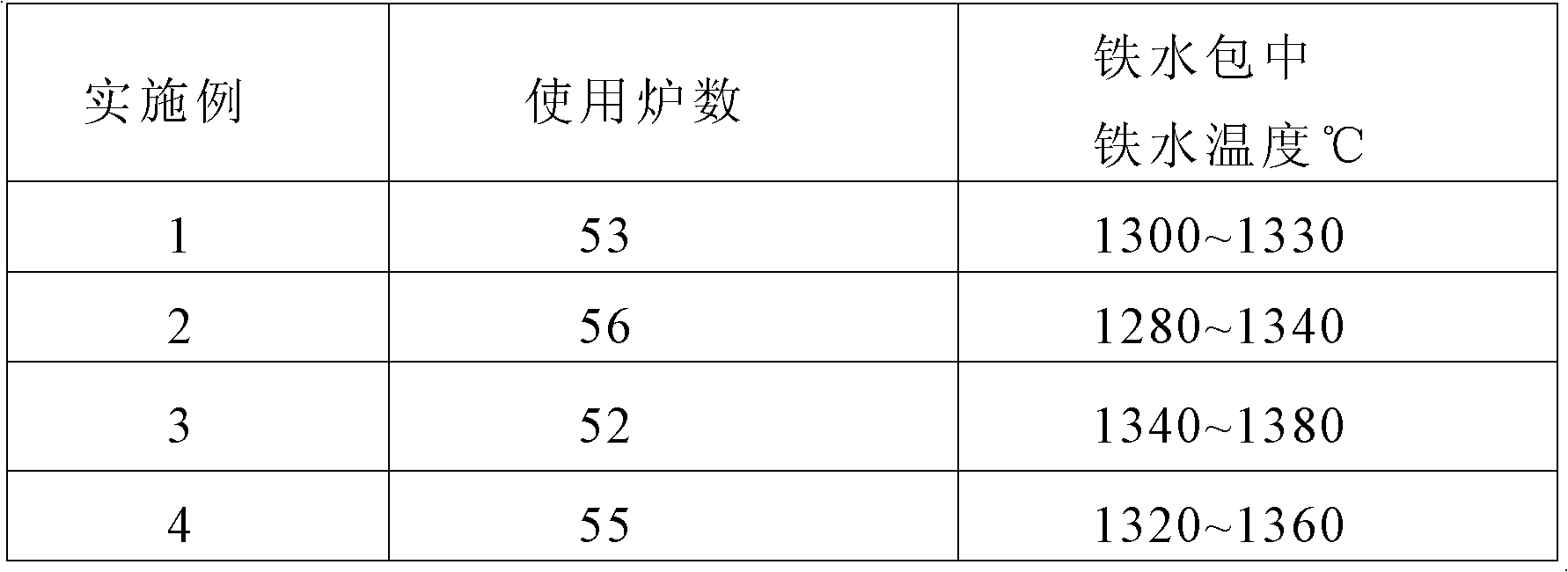

Examples

Embodiment 1

[0016] A casting material for ladle slag removal board, which consists of the following components by weight: 50kg of mullite, 17kg of andalusite, 20kg of bauxite, 4kg of pure calcium aluminate cement, 5kg of alumina micropowder, 4kg of silicon carbide micropowder, three Sodium polyphosphate 1.5kg, organic fiber 0.5kg; Al in selected mullite 2 o 3 The weight percentage of mullite particles is 75-77%, and the particle size of mullite particles is ≤5mm, among which, 3mm 2 o 3 The weight percentage content of the andalusite is ≥65%, and the particle size of andalusite is 3-1mm; Al in the selected bauxite powder 2 o 3 The weight percentage is ≥90%, the particle size is ≤0.088mm, the weight percentage of SiC in the selected silicon carbide powder is ≥90%, and the particle size is 200 mesh; the particle size of the selected organic fiber is 3-4mm, and the particle size of sodium tripolyphosphate is ≤0.088mm.

Embodiment 2

[0018] A castable for ladle slag removal board, which consists of the following components by weight: 70kg of mullite, 10kg of andalusite, 10kg of bauxite powder, 4kg of pure calcium aluminate cement, 5kg of alumina micropowder, 3kg of silicon carbide micropowder, Sodium tripolyphosphate 1.5kg, organic fiber 0.5kg, steel fiber 1kg; Al in selected mullite 2 o 3 The weight percentage of mullite particles is 70-75%, and the particle size of mullite particles is ≤5mm, among which, 3mm2 o 3 The weight percentage content of the andalusite is ≥60%, and the particle size of andalusite is 3-1mm; Al in the selected bauxite powder 2 o 3 Weight percentage ≥ 85%, particle size ≤ 0.088mm, Al in the selected pure calcium aluminate cement 2 o 3 The weight percentage content ≥ 70%; Al in the selected alumina micropowder 2 o 3 The weight percentage of SiC is more than 98%; the weight percentage of SiC in the selected silicon carbide micropowder is more than 90%; the particle size of the s...

Embodiment 3

[0020] A castable for ladle slag removal board, which consists of the following components by weight: 60kg of mullite, 10kg of andalusite, 20kg of bauxite powder, 3kg of pure calcium aluminate cement, 4kg of alumina micropowder, 5kg of silicon carbide micropowder, Sodium hexametaphosphate 1kg, sodium tripolyphosphate 0.5kg, organic 0.5kg, steel fiber 1kg; Al in selected mullite 2 o 3 The weight percentage of mullite particles is 70-75%, and the particle size of mullite particles is ≤5mm, among which, 3mm 2 o 3 The weight percentage content of the andalusite is ≥55%, and the particle size of andalusite is 3-1mm; Al in the selected bauxite powder 2 o 3 Weight percentage ≥ 90%, particle size ≤ 0.088mm, Al in the selected pure calcium aluminate cement 2 o 3 The weight percentage content ≥ 69%; Al in the selected alumina micropowder 2 o 3 The weight percentage of SiC in the selected silicon carbide powder is ≥98%; the weight percentage of SiC in the selected silicon carbide p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com