Municipal organic waste combined anaerobic treatment process and equipment

A technology for anaerobic treatment and organic waste, applied in anaerobic digestion treatment, sludge treatment, waste treatment and other directions, which can solve the problems of organic waste that cannot be mixed with feed for joint digestion, long residence time, and low conversion rate of organic matter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

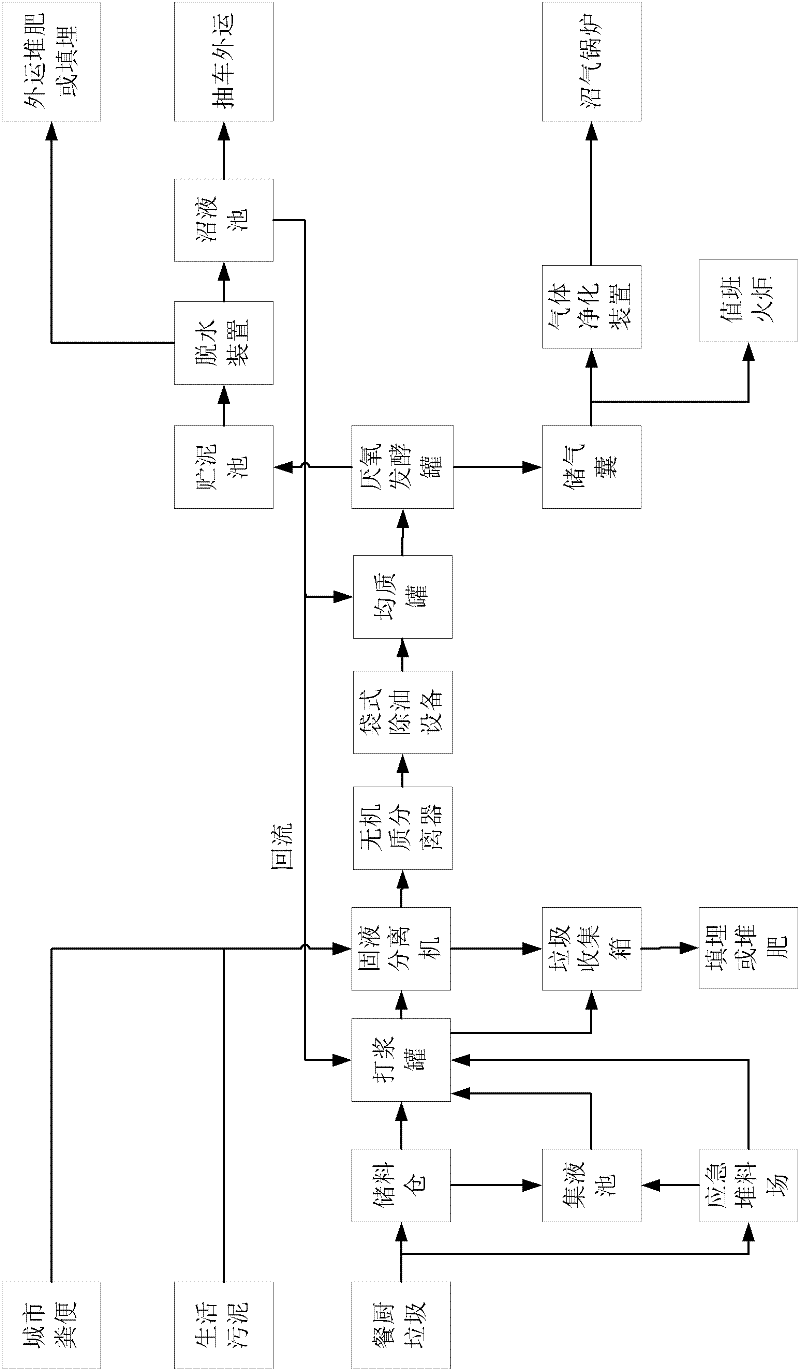

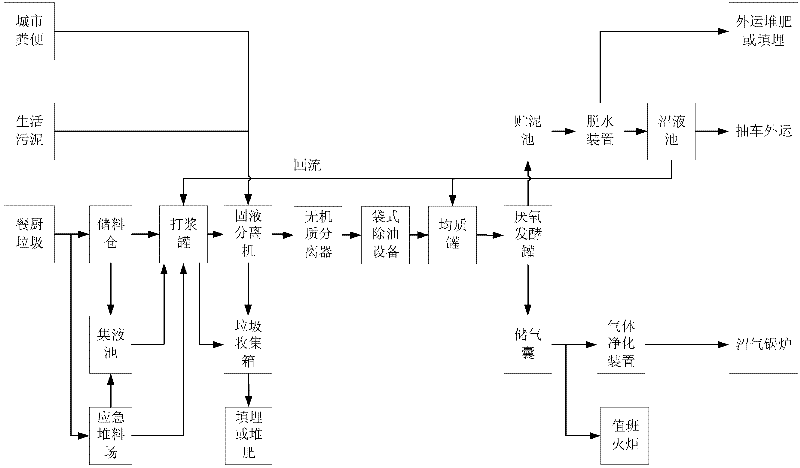

[0028] Municipal organic waste includes non-homogeneous semi-fluid waste (kitchen waste, fruit and vegetable waste, etc.) Pretreatment steps, anaerobic digestion treatment steps and biogas conversion treatment steps, specifically as figure 1 Shown:

[0029] (1) The preprocessing steps are:

[0030] Food waste first enters the storage bin or emergency stockyard, and the leachate in the storage bin or emergency stockyard seeps into the sump, and the leachate from the sump is pumped into the beating tank for circular beating treatment. Other high-solid waste remaining in the silo or emergency stockyard is crushed and then enters the beating tank for circular beating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com