Lactide continuous melt crystallization purification system and method

A technology of melting crystallization and purification method, which is applied in the field of lactide continuous melting crystallization purification system, which can solve the problems of large fluctuations in product quality, unstable product quality, and limited scope of application, so as to reduce the risk of thermal decomposition and improve energy utilization. High efficiency and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

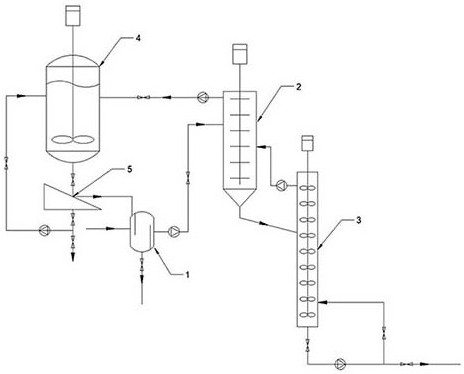

[0026] A lactide continuous melting crystallization purification system, such as figure 1As shown, it includes a mixed feed system 1, a crude lactide crystallization section 2, a crystal sweating purification section 3, and a mother liquor crystallization recovery section 4, wherein the mixed feed system is connected to the crude lactide crystallization section through a pumping pipeline, and the crude The crystal slurry outlet is set at the bottom of the lactide crystallization section, and is connected to the crystal sweating purification section through the delivery pipeline; the mother liquor outlet is connected to the mother liquor crystallization recovery section through the pumping pipeline at the top, and the product outlet and the reflux liquid inlet are set at the bottom of the crystal sweating purification section. The extraction and return of the product are realized through the connection of the pumping pipeline; the mother liquor outlet is set on the top, and the ...

Embodiment 2

[0032] Using the purification system described in Example 1, the crude lactide provided by a certain factory was used as the raw material to carry out the lactide continuous melting crystallization purification experiment. The crude product feed concentration was determined to be 85wt% (the specific composition was 85wt% lactide, 5wt% meso-lactide, 4wt% lactic acid, 0.8wt% moisture, and 5.2wt% oligomers). During the start-up stage, the temperature of the entire system container and pipeline is kept higher than the melting point of lactide by controlling the heat exchange medium, and the system is filled with liquid-phase crude lactide. After the material is filled with the system, the temperature of the heat exchange medium in the crude lactide crystallization section and flow, start to cool down and crystallize, and when the crystallizer reaches a certain suspension density, open the bottom transfer pumping pipeline to transport the crystal slurry to the crystal sweating purif...

Embodiment 3

[0034] Using the purification system described in Example 1, the crude lactide provided by a certain factory was used as the raw material to carry out the lactide continuous melting crystallization purification experiment. The crude product feed concentration was determined to be 91wt% (the specific composition was 91wt% lactide, 3wt% meso-lactide, 1.9wt% lactic acid, 0.4wt% moisture, and 3.7wt% oligomers). During the start-up stage, the temperature of the entire system container and pipeline is kept higher than the melting point of lactide by controlling the heat exchange medium, and the system is filled with liquid-phase crude lactide. After the material is filled with the system, the temperature of the heat exchange medium in the crude lactide crystallization section and flow, start to cool down and crystallize, and when the crystallizer reaches a certain suspension density, open the bottom transfer pumping pipeline to transport the crystal slurry to the crystal sweating pur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com