Mordenite preparation method

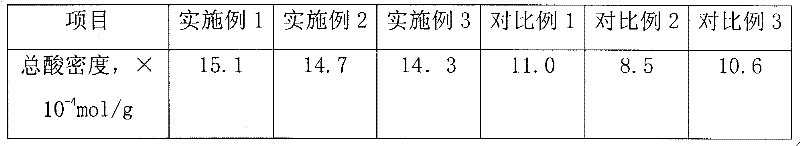

A technology of mordenite and pseudo-boehmite, which is applied in the direction of crystalline aluminosilicate zeolite, can solve the problems of unreported mordenite, high yield of unreported mordenite, specific surface area, acid density and catalytic activity reduction, etc. To achieve the effect of enriching acid center density, increasing crystallinity and improving activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This example is to illustrate the preparation process of mordenite provided by the present invention without mother liquor circulation.

[0034] Add 3.5 grams of 37 weight percent concentrated hydrochloric acid (chemically pure, Beijing Reagent Company) in 1 liter of chemical water and stir evenly, add pseudo-boehmite powder (industrial product, produced by China Aluminum Corporation Shandong Aluminum Factory, solid content 66.1 weight percent) ) 121 grams and stirred for 30 minutes, added silica gel (industrial products, produced by Qingdao Ocean Chemical Co., Ltd., 99.7 weight percent of silicon dioxide, 0.18 weight percent of sodium oxide, 0.085 weight percent of calcium oxide, 92.7 weight percent of solid content) 600 grams, and then Rinse with about 220ml of water, stir well and dry at 120°C / 2 hours. The chemical composition is: 13.2% by weight of aluminum oxide, 0.16% by weight of sodium oxide, 0.40% by weight of chlorine, and 87.6% by weight of solid content.

...

Embodiment 2

[0038] This example is to illustrate the preparation process of mordenite provided by the present invention under the mode of mother liquor circulation.

[0039] Get 650 milliliters of crystallization mother liquors obtained in Example 1, add 131 grams of sodium hydroxide (chemically pure reagent, Beijing Reagent Company, 95% by weight) and 11 grams of sodium chloride (same as above) and stir to make it dissolve, then add according to implementation 650 g of the silicon-aluminum mixture prepared in the manner of Example 1 was stirred at room temperature for 4 hours, crystallized at 120° C. for about 10 hours, and then crystallized at 200° C. for 65 hours.

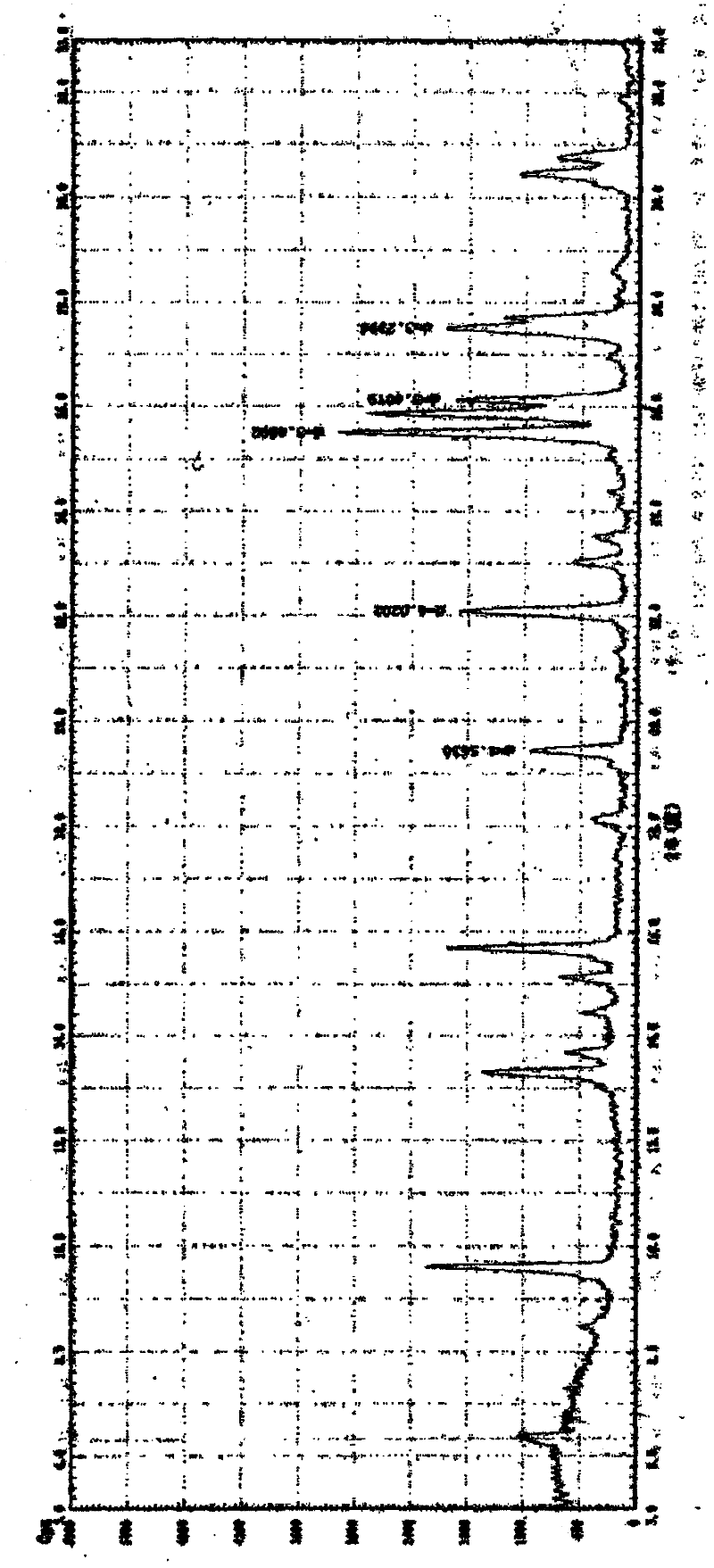

[0040] The X-ray diffraction pattern of embodiment 2 sample sees specification sheet appendix figure 2 , sodium oxide 7.9% by weight, silicon-aluminum molar ratio 10.9, grain size distribution range of 10-20 microns.

Embodiment 3

[0042] This example provides the process of preparing mordenite by using the mother liquor after multiple cycles in the present invention.

[0043] Get 650 milliliters of crystallization mother liquors obtained after 10 synthetic crystallization cycles, add 130 grams of sodium hydroxide (same as above) and 10 grams of sodium chloride (same as above) and stir to make it dissolve, then add the prepared by the method of embodiment 1 650 g of the silicon-aluminum mixture was stirred at room temperature for 6 hours, crystallized at 120°C for about 12 hours, and then crystallized at 200°C for 49 hours.

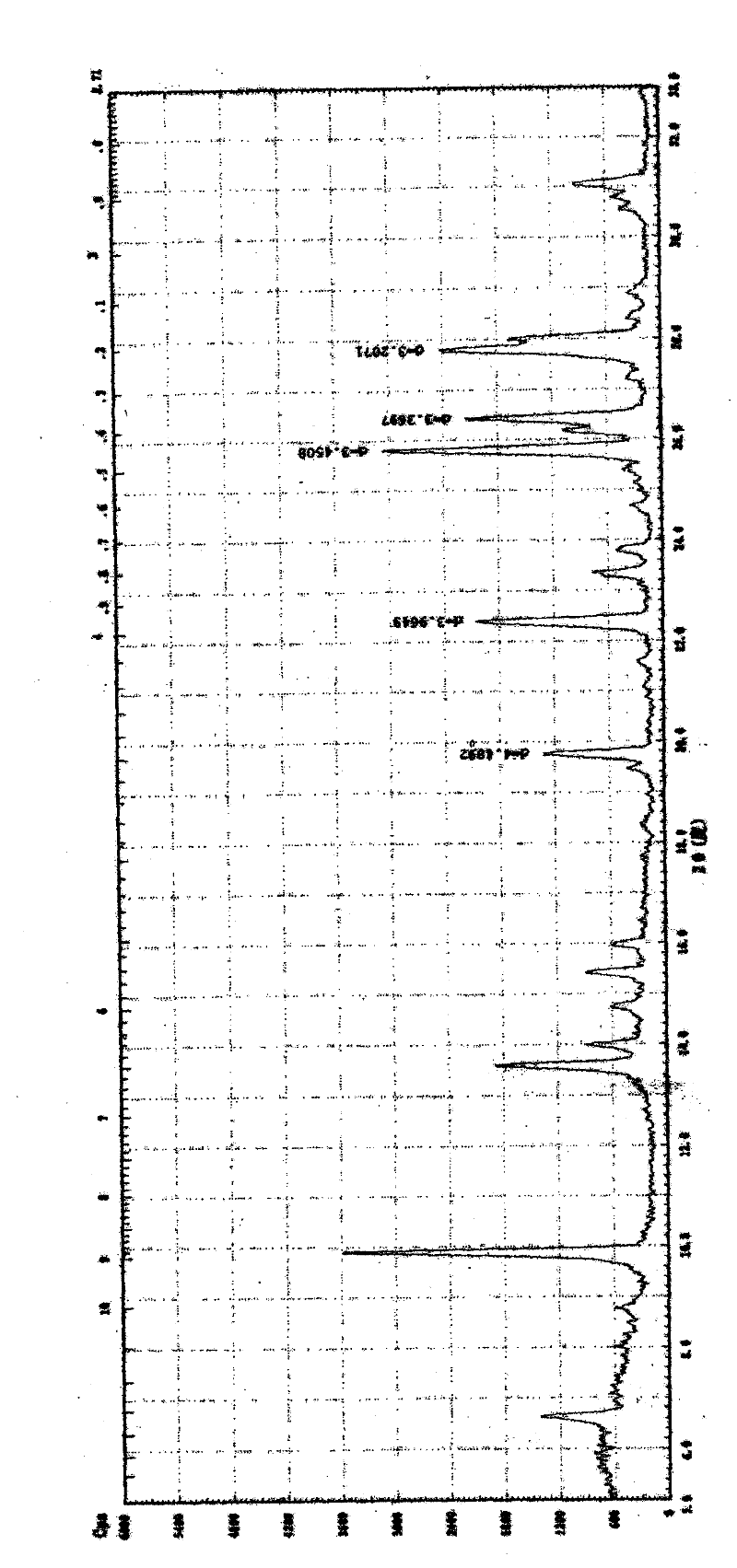

[0044] The X-ray diffraction pattern of embodiment 3 samples and description attached figure 2 Similarly, the sodium oxide is 7.9% by weight, the molar ratio of silicon to aluminum is 10.9, and the grain size distribution range is 10-20 microns.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com