Rubber conducting plate with multi-layer structure and conducting particles

A multi-layer structure, conductive plate technology, applied in the direction of rubber layered products, layered products, metal layered products, etc., can solve the problems of blocking conductive lines, wrong conduction, deformation and protrusion, etc., to prevent pollution, Clear function and shortened service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

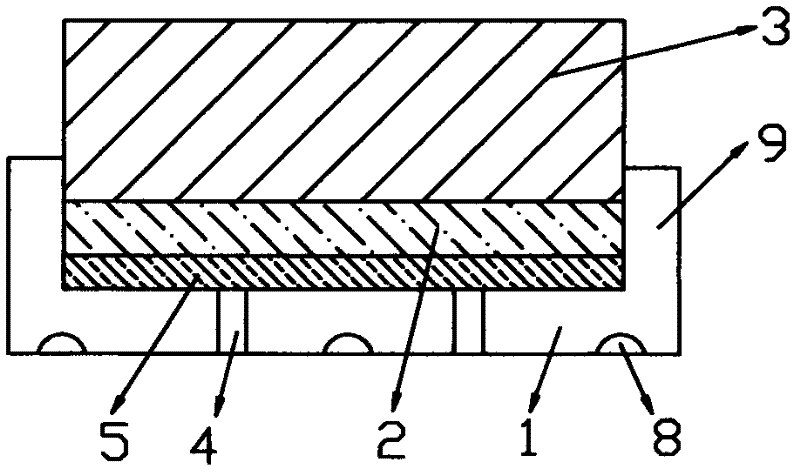

[0025] Embodiment 1: as figure 2 The rubber conductive particle with a multi-layer structure shown is composed of a conductive layer 1 , a transition layer 2 and an elastic layer 3 bonded together. The conductive layer 1 is a smooth dense metal silver sheet, the transition layer 2 is a composite sheet made of polyester film and a second layer of dense metal sheet 5 made of stainless steel, and the elastic layer 3 is a rubber sheet. The thickness of the conductive layer 1 is 0.05mm, the thickness of the transition layer 2 is 0.1mm, and the thickness of the elastic layer 3 is 2mm.

[0026] There are many randomly arranged holes 4 and a small number of dents 8 on the dense metal sheet of the conductive layer 1, and the maximum diameter of the holes 4 is less than 2 mm. The edge of the conductive layer 1 includes a flange 9 that bends toward the transition layer 2 and surrounds the transition layer, so as to further ensure that the elastic layer 3 will not be exposed from the pe...

Embodiment 2

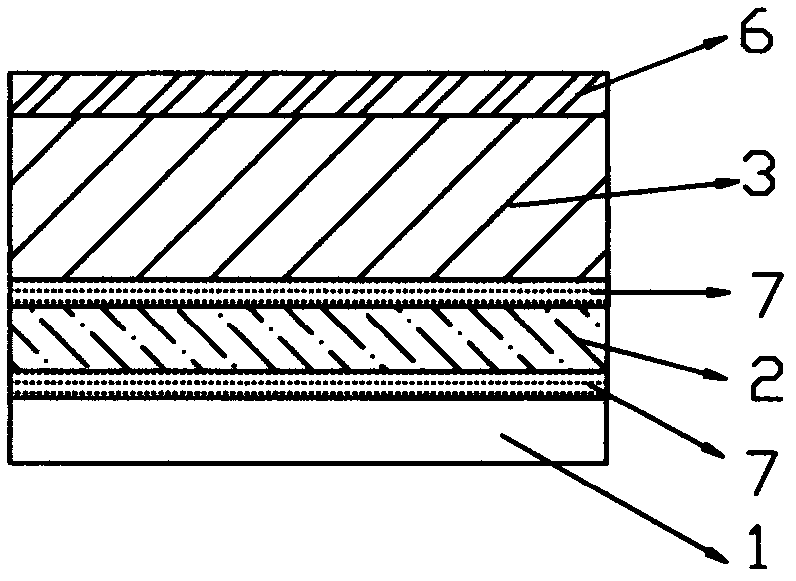

[0028] Embodiment 2: as image 3 The rubber conductive plate with multi-layer structure shown is composed of conductive layer 1, transition layer 2 and elastic layer 3 bonded and compounded. image 3 Among them, the conductive layer 1 is a mesh-shaped copper sheet; the transition layer 2 is a polyimide film; the elastic layer 3 is a rubber-plastic sheet. The thickness of the conductive layer 1 is 0.1 mm, the thickness of the transition layer 2 is 0.5 mm, and the thickness of the elastic layer 3 is 3 mm. A polymer adhesive layer 7 is formed between the conductive layer 1 and the transition layer 2 , and between the transition layer 2 and the elastic layer 3 . The outer surface of the elastic layer 3 also has a second polymer film 6 isolation layer. This embodiment is suitable for use as a conductive material or as an electromagnetic shielding material.

Embodiment 3

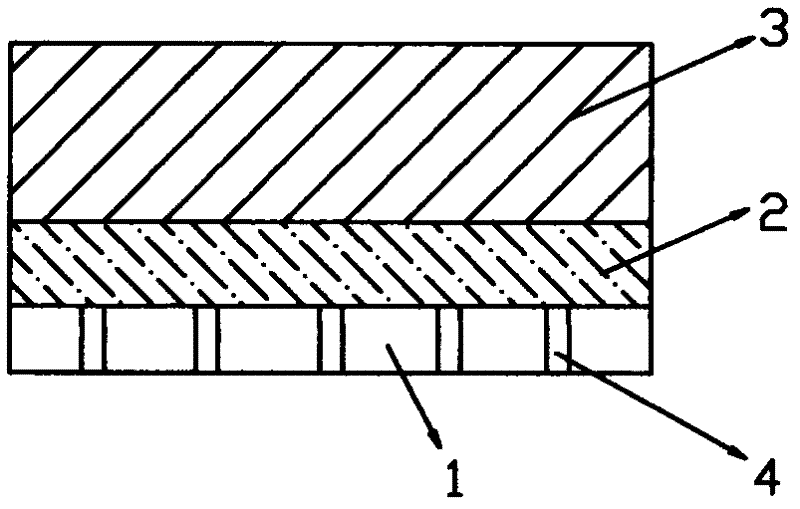

[0029] Embodiment 3: as figure 1 The rubber conductive plate shown is composed of a conductive layer 1 , a transition layer 2 and an elastic layer 3 . The conductive layer 1 is a metal plating layer, the transition layer 2 is a polycarbonate film; the elastic layer 3 is a rubber layer made of liquid silicone rubber. A 0.125mm thick polycarbonate film is used as the transition layer 2, and the surface is first plated with 0.5μm thick metal nickel and then 0.025μm thick gold by vacuum sputtering coating method. The plating layer forms the conductive layer 1 . Before vacuum sputtering nickel plating, the polycarbonate film is treated with plasma in a vacuum sputtering chamber, which can improve the adhesion between the metal nickel layer and the polycarbonate film. Coat one side of the polycarbonate film without metal plating with a primer that improves the adhesion between polycarbonate and silicone rubber, and then mold the liquid silicone rubber on the polycarbonate film at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com