Device for bearing hydrogen embrittlement peeling reproducibility test

A reproducibility and bearing technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of inability to carry out research in a targeted manner, the research cannot be carried out well, and the lack of experimental data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

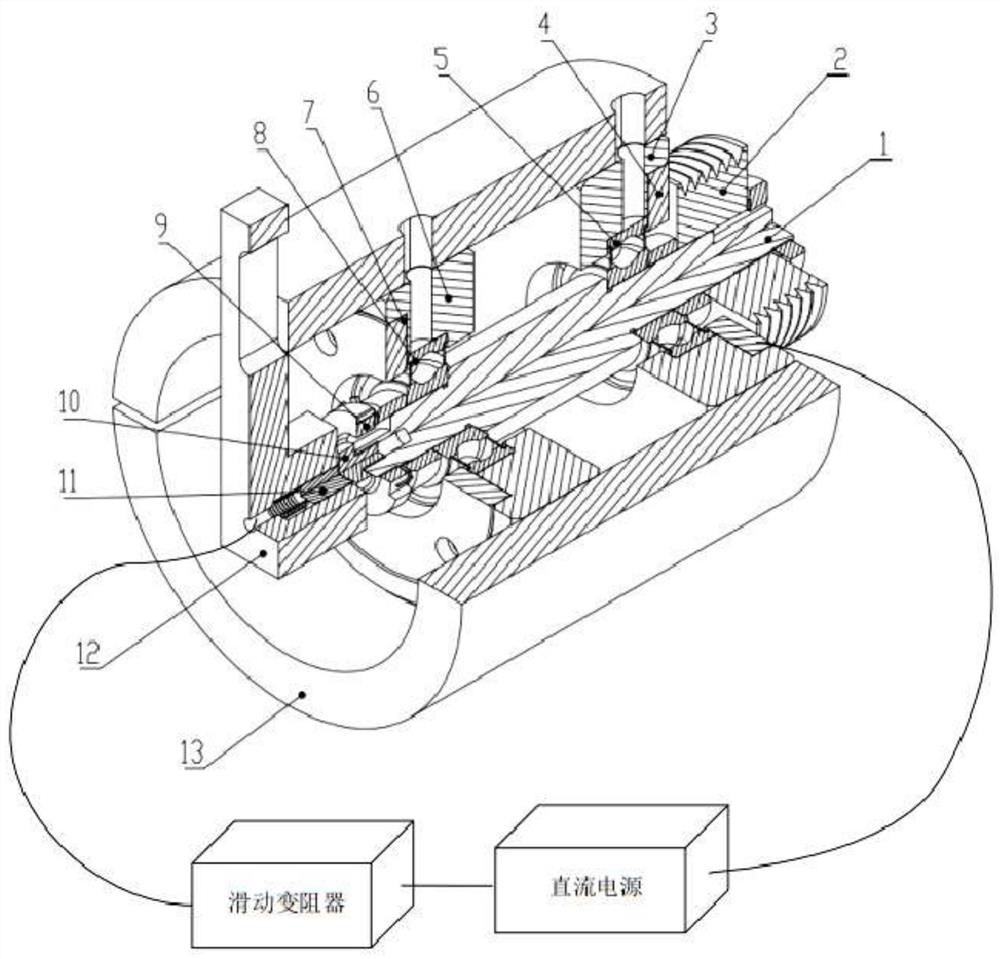

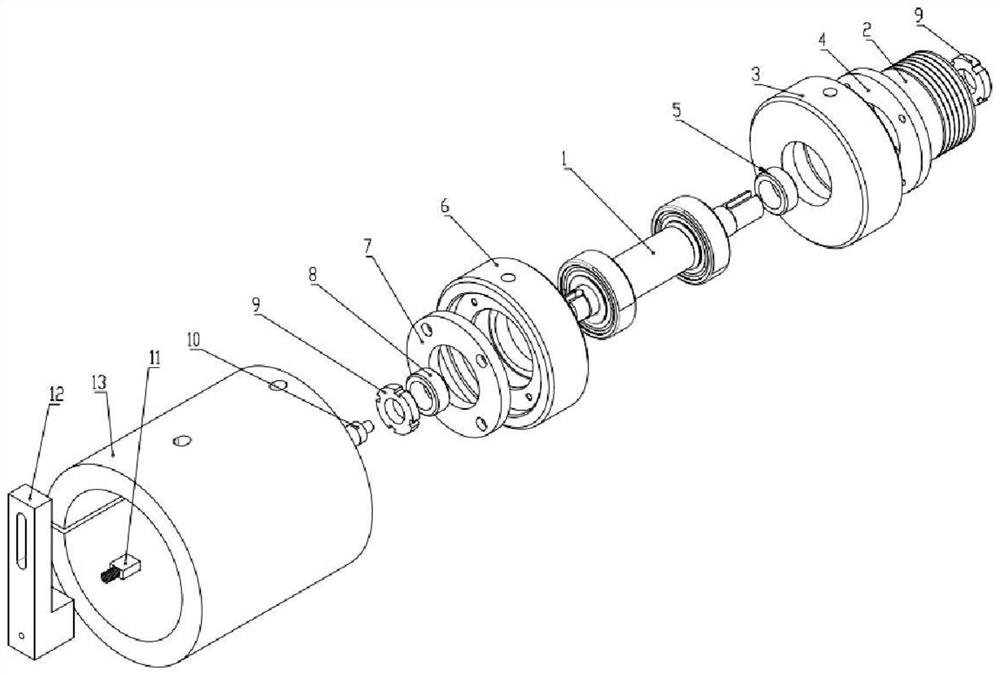

[0020] The implementation of the apparatus for use in a bearing hydrogen-cropbruff reproduction test, for example Figure 1 to 2 As shown: including the frame body 13, the power supply unit and the test shaft 1, the frame body 13 is provided with a first carrier seat 3 and a second carrier 6, and the test shaft 1 passes through the first carrier 3 and the second. The carrier 6 is disposed, the test shaft 1 is combined with the first carrier 3 forming a first carrier for accommodating the bearing 5 to be tested, and the test shaft 1 and the second carrier 6 are formed for accompanying The second bearing groove of the test bearing 8, the test shaft 1 is provided with a driving member 2 for driving the test shaft 1, and the other end is provided with a terminal 10, the frame body 13 corresponding to the terminal 10 position setting with a wiring. The terminal 10 is connected to the carbon brush 11, the power supply unit two wiring ends are electrically connected to one end of the carb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com