Stirring device for spraying anti-static paint

A stirring device and anti-static technology, which is applied to mixers with rotating stirring devices, mixer accessories, dissolving, etc., can solve the problems that cannot meet the requirements of anti-static paint spraying, and achieve good spraying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

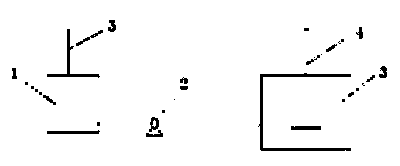

[0013] A stirring device for spraying antistatic paint according to the present invention, see figure 1 , the mixing device includes a storage tank 1, a pressure pump 2, a mixing tank 3 and an agitator 4, the storage tank 1 is connected to the mixing tank 3 through the pressure pump 2, the agitator 4 is arranged in the middle position in the mixing tank, and the agitator is decelerated The machine is connected to the motor. The stirring speed of the stirrer is 2000 rpm. Storage barrel is connected with the nozzle of spray gun by pipeline 5.

[0014] When using, pour the anti-static paint into the mixing bucket, and use a stirrer to stir the anti-static paint to prevent the conductive powder in the anti-static paint from settling. At the same time, prevent the conductive powder from being too fine when stirring, which will affect the conductive effect. , The stirring speed of the agitator is very important. If the stirring speed is too fast, the conductive powder will be beat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com