Hydrogel, its preparation method and its application in heavy metal waste water treatment

A technology of hydrogel and heavy metal ions, which is applied in the fields of adsorption water/sewage treatment, alkali metal compounds, chemical instruments and methods, etc., can solve the problems of troublesome operation, affecting adsorption performance, complex hydrogel process, etc., and achieves good results. , the preparation method is simple, the effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Weigh a certain mass of maleamic acid (Maleamic acid) and dissolve it in deionized water, and use it as component A after fully dissolving. Then, add a certain amount of hydroxyethyl acrylate monomer (HEA for short) to the above solution, mix well, as component B; deionized water as component C, according to (A+B):C ratio of 3:7 (ml / ml) for mixing, where A:B is 1:9 (mol / mol). Ultrasonic treatment was then performed for 10 min.

[0031] 2. After nitrogen filling, at a temperature of -95°C, the radiation dose range is controlled within 1×10 3 ~1×10 6 Gy, using high-energy rays ( 60 Co-γ-ray) irradiation polymerization to form polymer hydrogels.

[0032] 3. Cut the irradiated hydrogel into small pieces of 1cm×1cm×1cm, put them in a conical flask, wash them with deionized water several times, and dry them at 45°C.

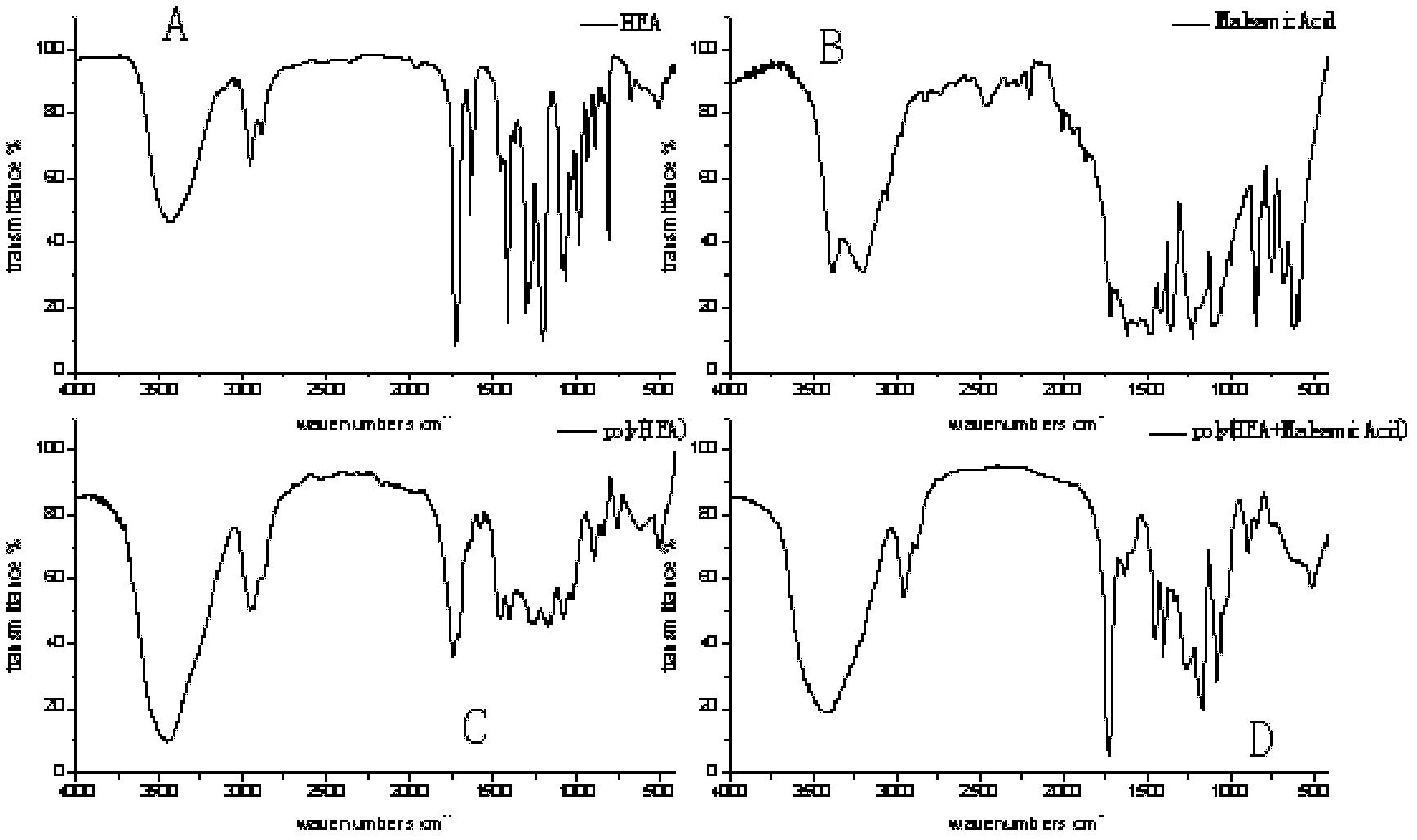

[0033] 4. Characterize the structure and composition of the product, including the analysis of functional groups on the surface of the hydrogel using F...

Embodiment 2

[0035] 1. Weigh a certain mass of maleamic acid (Maleamic acid) and dissolve it in deionized water, and use it as component A after fully dissolving. Then, add a certain amount of hydroxyethyl acrylate monomer (HEA for short) to the above solution, mix evenly, as component B; deionized water as component C, according to (A+B):C is 4:6 (ml / ml) for mixing, where A:B is 3:7 (mol / mol). Ultrasonic treatment was then performed for 10 min.

[0036] 2. After nitrogen filling, at a temperature of -78°C, the radiation dose range is controlled within 1×10 3 ~1×10 6 Gy, using high-energy rays ( 137 Cs-γ-ray) irradiation polymerization to form polymer hydrogels.

[0037] 3. Cut the irradiated hydrogel into small pieces of 1cm×1cm×1cm, put them in a conical flask, wash them with deionized water several times, and dry them at 45°C.

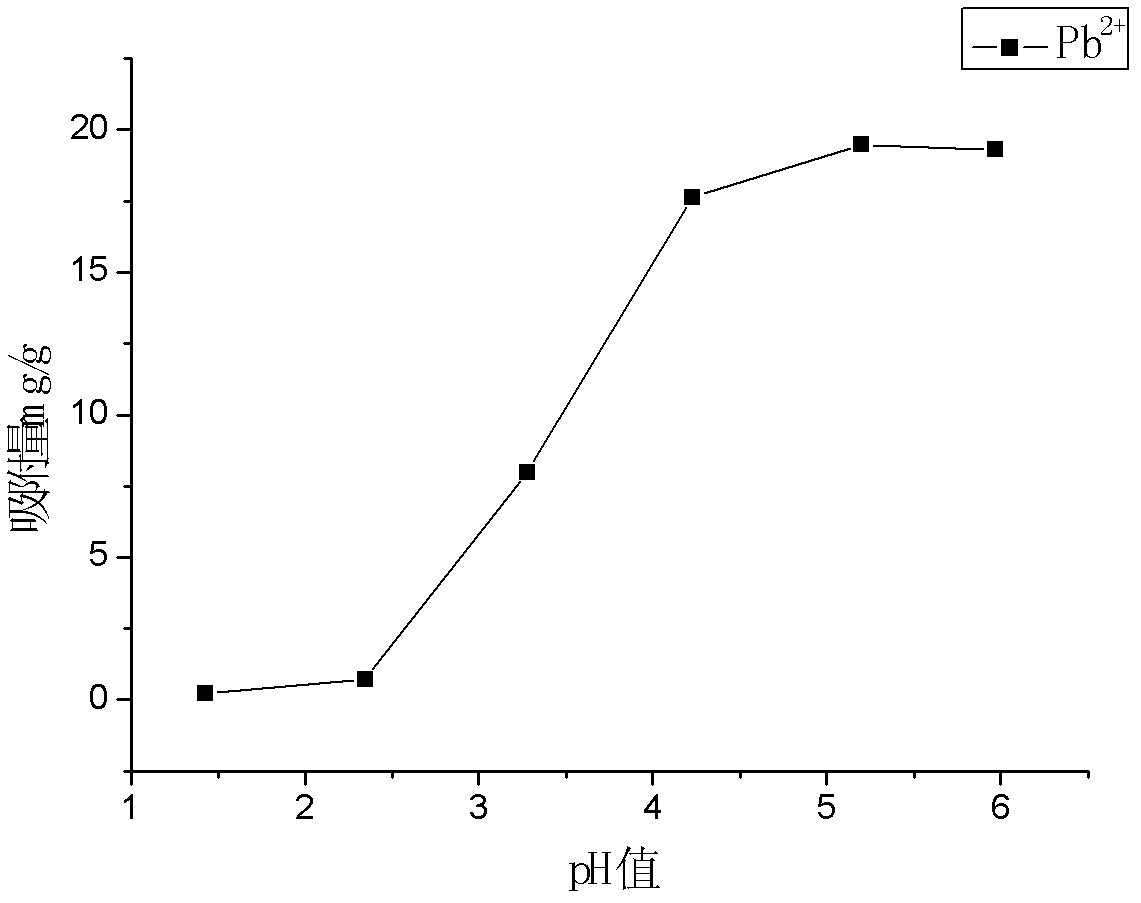

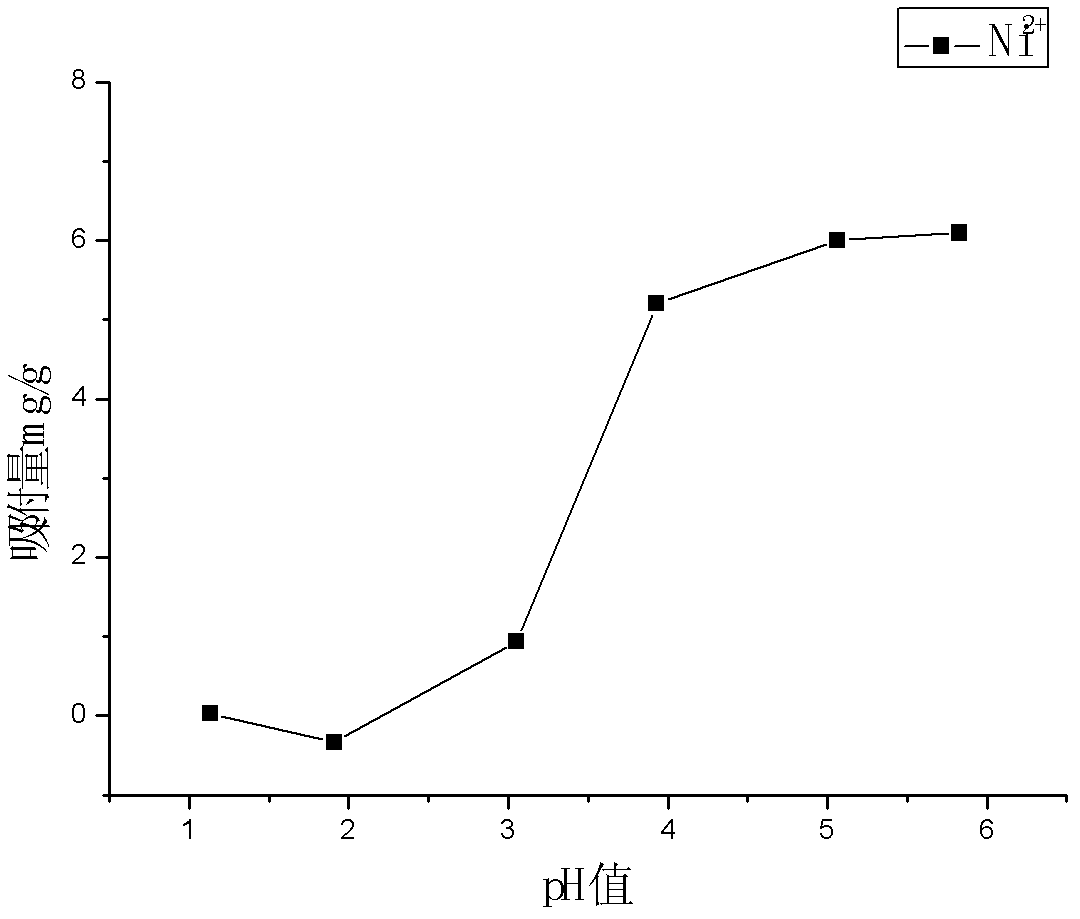

[0038]4. Weigh five parts of 0.1g hydrogel dried product and put them in 100ml Erlenmeyer flask respectively, then add 50ml, 1g / L Pb respectively 2+ 、Ni ...

Embodiment 3

[0040] 1. Weigh a certain mass of maleamic acid (Maleamic acid) and dissolve it in deionized water, and use it as component A after fully dissolving. Then, add a certain amount of hydroxyethyl acrylate monomer (HEA for short) to the above solution, mix well, as component B; deionized water as component C, according to (A+B):C is 2:8 (ml / ml) for mixing, where A:B is 1:1 (mol / mol). Ultrasonic treatment was then performed for 10 min.

[0041] 2. After nitrogen filling, at a temperature of -63°C, the radiation dose range is controlled within 1×10 3 ~1×10 6 Gy, using high-energy rays ( 60 Co-γ-ray) irradiation polymerization to form polymer hydrogels.

[0042] 3. Cut the irradiated hydrogel into small pieces of 1cm×1cm×1cm, put them in a conical flask, wash them with deionized water several times, and dry them at 45°C.

[0043] 4. Weigh five parts of 0.1g hydrogel dried product and put them in 100ml Erlenmeyer flask respectively, then add 50ml, 1g / L Pb respectively 2+ 、Ni 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com