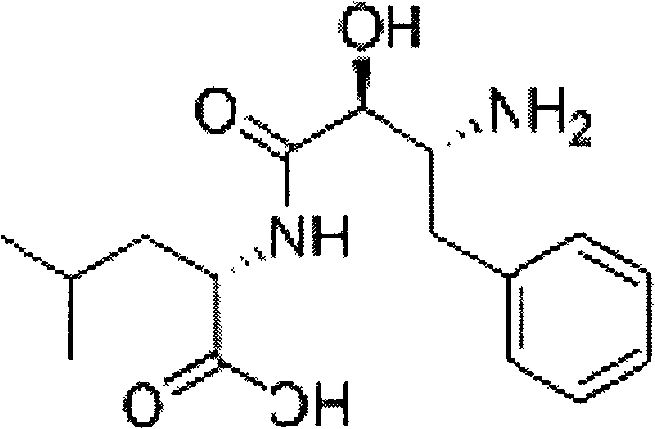

Method for preparing ubenimex hydrolysis intermediates

A technology of ubimethoxine and intermediates, which is applied in the field of preparation of ubimethoxine hydrolysis intermediates, can solve problems such as being unsuitable for large-scale production, consume a lot of energy, waste solvents and the like, and achieve solvent and energy saving and yield High, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

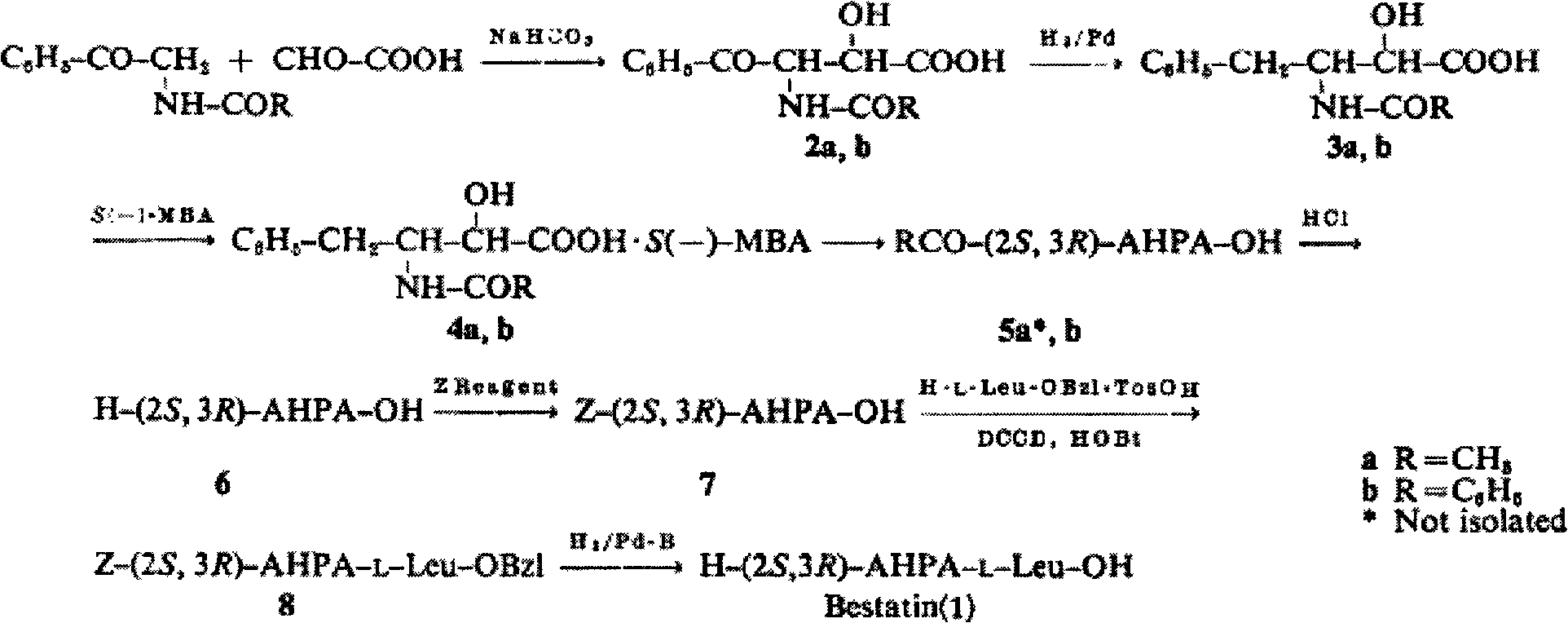

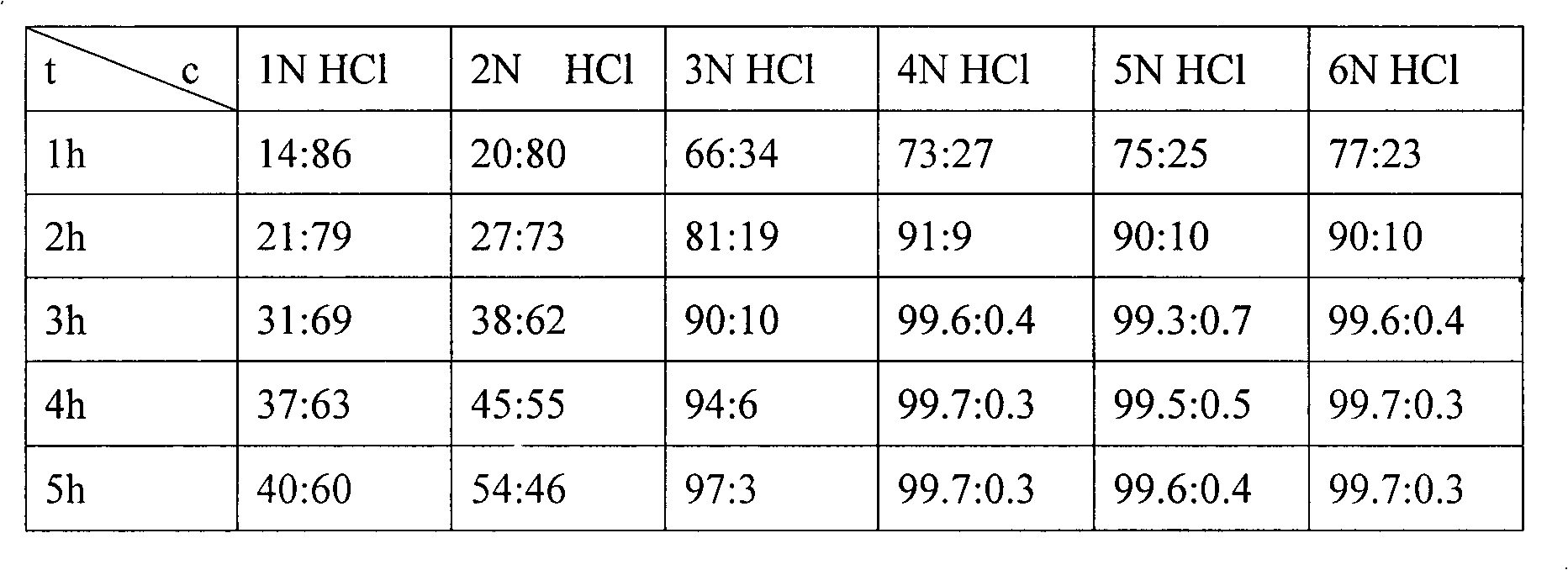

Method used

Image

Examples

Embodiment 1

[0025] Put 200g of (2S, 3R)-3-acetamido-2-hydroxy-4-phenylbutyric acid S(-)-α-phenethylamine salt into the reactor, add 640g of 4N hydrochloric acid aqueous solution, at 50°C Stir for 3 hours, add 4N sodium hydroxide solution to adjust pH=8.2, and filter with suction to obtain 109.6 g of crude product. The crude product was heated to 90°C with 986.4g of 60% DMF-water solution to dissolve, stirred and crystallized at room temperature, filtered with suction, and dried to obtain 103.63g of white crystals with a purity of 98.6% and an optical rotation of +31.7° (C=1, 1N HCl ), yield 93.27%.

Embodiment 2

[0027] Put 200g of (2S, 3R)-3-acetamido-2-hydroxy-4-phenylbutyric acid S(-)-α-phenethylamine salt into the reactor, add 640g of 4N aqueous hydrochloric acid, at 70°C Stir for 3 hours, add 6N sodium hydroxide solution to adjust pH=8.2, and filter with suction to obtain 110.1 g of crude product. The crude product was heated to 90°C with 990.9g of 60% DMF-water solution to dissolve, stirred and crystallized at room temperature, filtered with suction, and dried to obtain 102.98g of white crystals with a purity of 98.5% and an optical rotation of +31.5° (C=1, 1N HCl), yield 92.87%.

Embodiment 3

[0029] Put 200g of (2S, 3R)-3-acetamido-2-hydroxy-4-phenylbutyric acid S(-)-α-phenethylamine salt into the reactor, add 1000g of 4N hydrochloric acid aqueous solution, at 60°C Stir for 3 hours, add 6N sodium hydroxide solution to adjust pH=8.2, and filter with suction to obtain 105.4 g of crude product. The crude product was heated to 90°C with 700g of 70% DMF-water solution to dissolve, stirred and crystallized at room temperature, suction filtered, and dried to obtain 103.50g of white crystals with a purity of 98.2% and an optical rotation of +31.4° (C=1, 1N HCl ), yield 93.21%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com