Algae organic fertilizer and preparing process thereof

A preparation process and organic fertilizer technology, applied in the direction of organic fertilizers, etc., can solve the problems of destroying the active ingredients of seaweed, affecting coastal landscapes, polluting the environment, etc., achieving significant comprehensive economic benefits, avoiding degradation and denaturation, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment 1 Preparation of seaweed organic fertilizer

[0032] Proceed as follows:

[0033] (1) Desanding the seaweed, drying it in the sun, so that the water content is lower than 10% (mass percentage), to obtain dried seaweed;

[0034] (2) Pulverize the above-mentioned dried seaweed to obtain seaweed powder, the particle size of seaweed in seaweed powder is not more than 0.5cm×0.5cm, then seaweed powder and water are mixed in a mass ratio of 1:20, and 0.1mol / L Adjust the pH to 3 with hydrochloric acid, adjust the temperature to 50°C, and ultrasonically break the wall for 10 minutes with an ultrasonic power of 125w; Ultrasonic power 150w, get the extract;

[0035] (3) Filter and centrifuge the above extract to remove insoluble matter, then decolorize the resulting clear liquid through 5% (mass percent) activated carbon, after decolorization, concentrate, control the concentration temperature at 50°C, and keep the concentrated steam pressure at 0.03 ~0.05Mpa, concen...

Embodiment 2

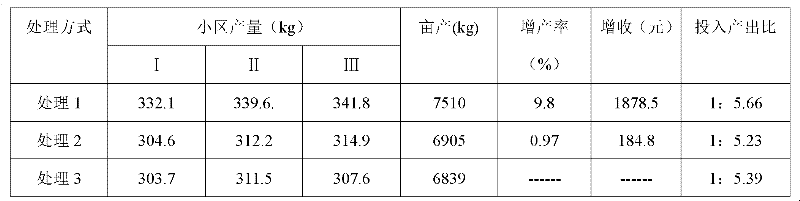

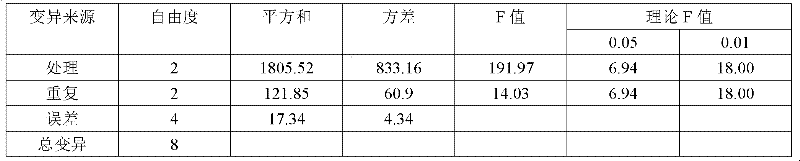

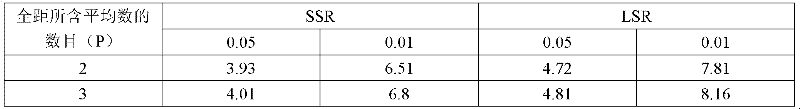

[0039] Example 2 Effect of seaweed organic fertilizer

[0040] Application test report of alginic acid water-soluble fertilizer on cucumber

[0041] In order to verify the effect of the application of seaweed organic fertilizer on cucumber production, to explore the effect of this fertilizer on the physiological characters and yield of cucumber, and to provide a basis for high-yield, high-quality, and high-efficiency cultivation of cucumber, this experiment was set up, and the experimental results are reported as follows:

[0042] 1. Test time and place:

[0043] 1.1 Test time: September 30, 2010 - January 20, 2010

[0044] 1.2 Test site: Niyi Village, Songcun Town, Wendeng City

[0045] 2. Test materials and methods

[0046] 2.1 Test soil

[0047] Soil type

Organic matter (g / kg)

Alkaline nitrogen (mg / kg)

Available phosphorus (mg / kg)

Available Potassium (mg / kg)

PH value

brown loam

9.14

95.2

124.7

131.1

6.1 ...

Embodiment 3

[0076] Example 3 Preparation of seaweed organic fertilizer

[0077] Proceed as follows:

[0078] (1) remove the sand from the seaweed, and dry it at 60° C. so that the water content is lower than 10% (mass percentage), to obtain dried seaweed;

[0079] (2) The above-mentioned dried seaweed is pulverized to obtain seaweed powder, the particle size of seaweed in seaweed powder is not more than 0.5cm×0.5cm, then seaweed powder and water are mixed in a mass ratio of 1:15, and 0.1mol / L Adjust the pH to 2 with hydrochloric acid, adjust the temperature to 50°C, and break the wall with ultrasonic waves. The breaking time is 12 minutes, and the ultrasonic power is 150w. Ultrasonic power 150w, get the extract;

[0080] (3) Filter and centrifuge the above extract to remove insoluble matter, then decolorize the resulting clear liquid through 5% (mass percent) activated carbon, after decolorization, concentrate, control the concentration temperature at 45°C, and keep the concentrated ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com