Pull boring processing method and device of cylinder barrel of thin-walled slender hydraulic cylinder

A technology for hydraulic cylinders and cylinder barrels, applied in the field of drawing and boring processing methods and devices for thin-walled and slender hydraulic cylinder barrels, to achieve the effects of improving fatigue strength, highlighting substantive features, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

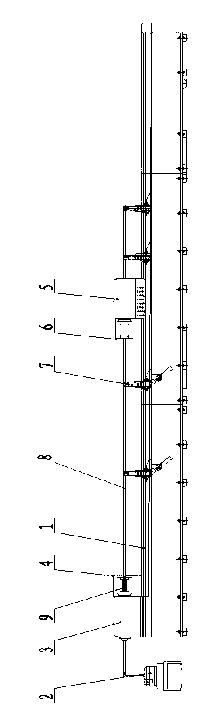

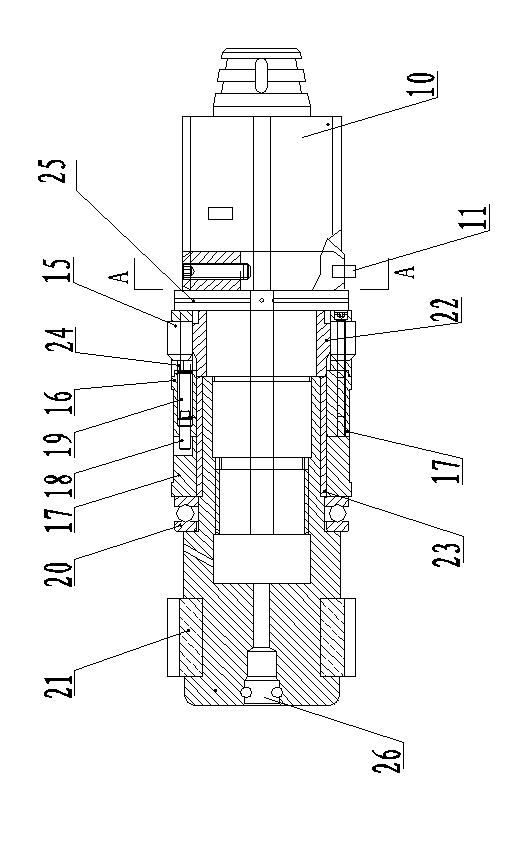

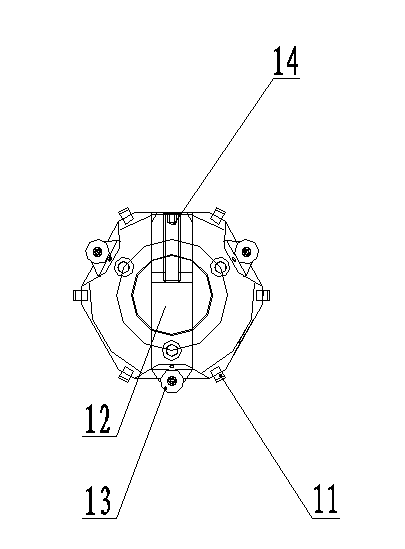

[0017] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0018] As can be seen from the accompanying drawings, a thin-walled and slender hydraulic cylinder barrel broaching and boring processing method of the present program includes the following steps:

[0019] A thin-walled and slender hydraulic cylinder barrel drawing and boring processing method comprises the following steps:

[0020] a. Put the thin-walled and slender hydraulic cylinder cylinder blank on the hydraulic control bracket of the drawing and boring processing device, adjust the center height of the hydraulic cylinder cylinder blank with the hydraulic control bracket, and pass the pull rod of the drawing and boring processing device through the cylinder barrel blank;

[0021] b. Install a tapered broaching and boring head on the pull rod, and connect a high-pressure liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com