Polydimethylsiloxane permeable vaporized gasoline desulphurization membrane and preparation method thereof

A technology of polydimethylsiloxane and pervaporation, which is applied in chemical instruments and methods, semi-permeable membrane separation, refining by dialysis, etc. It can solve the problem of unsatisfactory modification effect, expensive filler, and flux Reduce the problem of large drop, and achieve the effects of not being easy to secondary pollution, low cost, and simple membrane production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

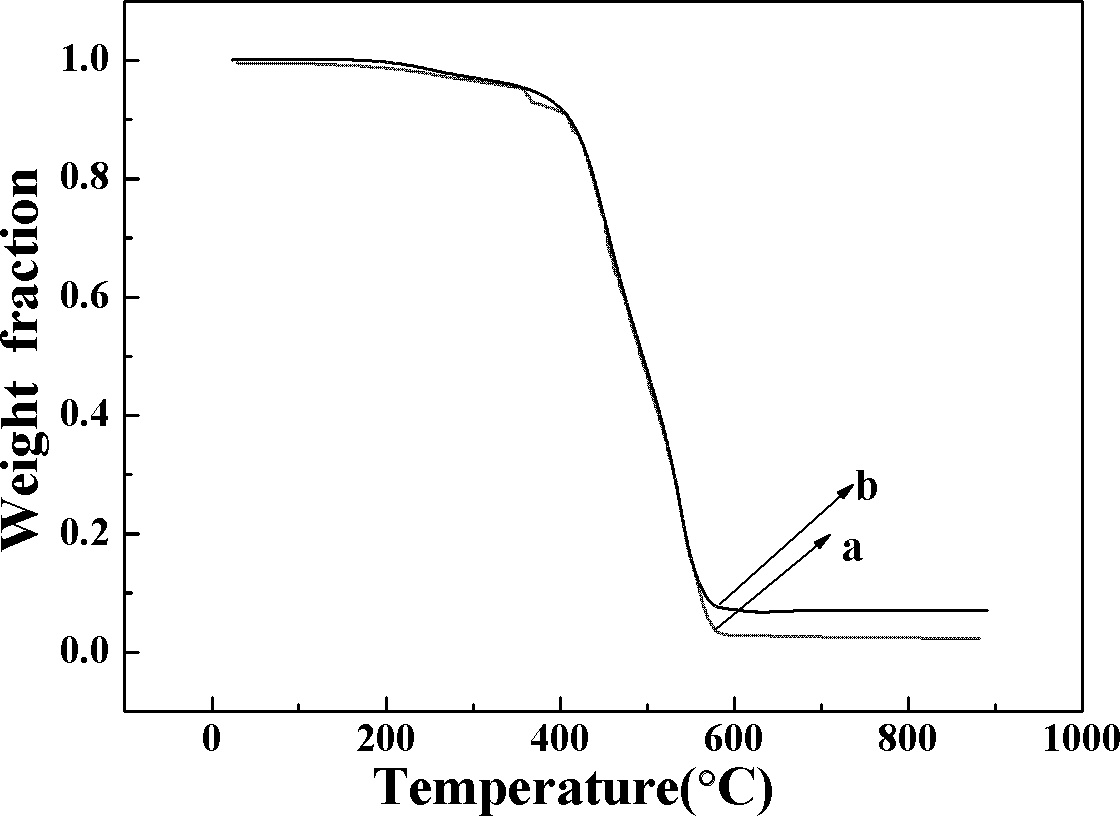

[0025] α-Al 2 o 3 Vacuum-dry at 120°C for 14 hours before use. Cut out a 12×12cm PTFE membrane, wash it with ethanol, flatten it, and spread it on an organic plate. Weigh 6.000g of PDMS, measure 11.6ml of n-heptane and 6.46ml of TEOS into the beaker, and stir magnetically for 1h. Weigh 0.375g of dried α-Al 2 o 3 Add the solution and sonicate for 1h. Then measure 0.2ml of dibutyltin laurate and add it to continue magnetic stirring for 10min, then measure 6ml of the solution and coat it on the PTFE membrane, and put it in an oven at 35°C to dry for 14h to form a film. A metal oxide-filled PDMS composite film was obtained.

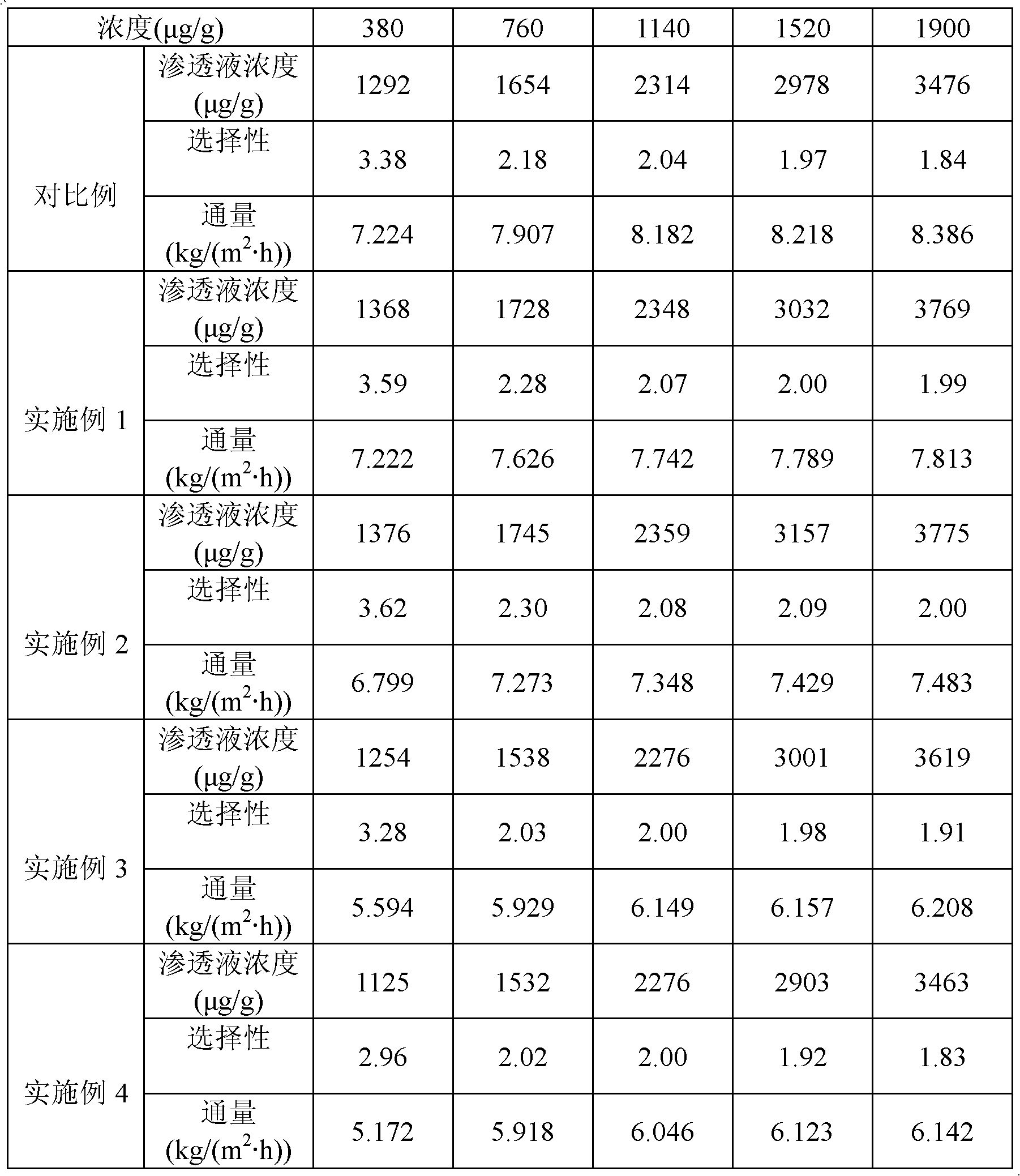

[0026] The evaluation of the pervaporation performance of the composite membrane was carried out by a pervaporation test device, using n-heptane-thiophene mixture to simulate gasoline, and the evaluation results showed that when the sulfur content of the feed liquid was 380 μg / g and the temperature was 30°C, the permeate obtained on the permeate side Th...

Embodiment 2

[0034] Weigh 6.000g of PDMS, measure 11.6ml of n-heptane and 6.46ml of TEOS into the beaker, and stir magnetically for 1h. Weigh 0.750g of dried α-Al 2 o 3 Add the solution, sonicate for 1 hour, add 0.2ml of dibutyltin laurate and continue magnetic stirring for 10 minutes. During this period, cut out a 12×12cm PAN film, wash it with ethanol, flatten it, and spread it on an organic plate. Measure 6ml of the solution and coat it on the PTFE membrane, and put it in an oven at 35°C to dry for 14h to form a membrane.

[0035] The evaluation of the pervaporation performance of the composite membrane is the same as in Example 1. The pervaporation results of the temperature in the range of 30-70°C are shown in Table 1, and the pervaporation results of the feed liquid sulfur content in the range of 380-1900 μg / g are shown in Table 2.

Embodiment 3

[0037] Weigh 6.000g of PDMS, measure 11.6ml of n-heptane and 6.46ml of TEOS into the beaker, and stir magnetically for 1h. Weigh 1.500g of dried α-Al 2 o 3 Add the solution, sonicate for 1 hour, add 0.2ml of dibutyltin laurate and continue magnetic stirring for 10 minutes. During this period, cut out a 12×12cm PEI film, wash it with ethanol, flatten it, and spread it on an organic plate. Measure 6ml of the solution and coat it on the PTFE membrane, and put it in an oven at 35°C to dry for 14h to form a membrane.

[0038] The evaluation of the pervaporation performance of the composite membrane is the same as in Example 1. The pervaporation results of the temperature in the range of 30-70°C are shown in Table 1, and the pervaporation results of the feed liquid sulfur content in the range of 380-1900 μg / g are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com