Method for producing daptomycin by fermentation

A technology of daptomycin and fermented liquid, which is applied in the field of fermentative production of daptomycin and antibiotics to achieve the effects of wide sources, fast utilization and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

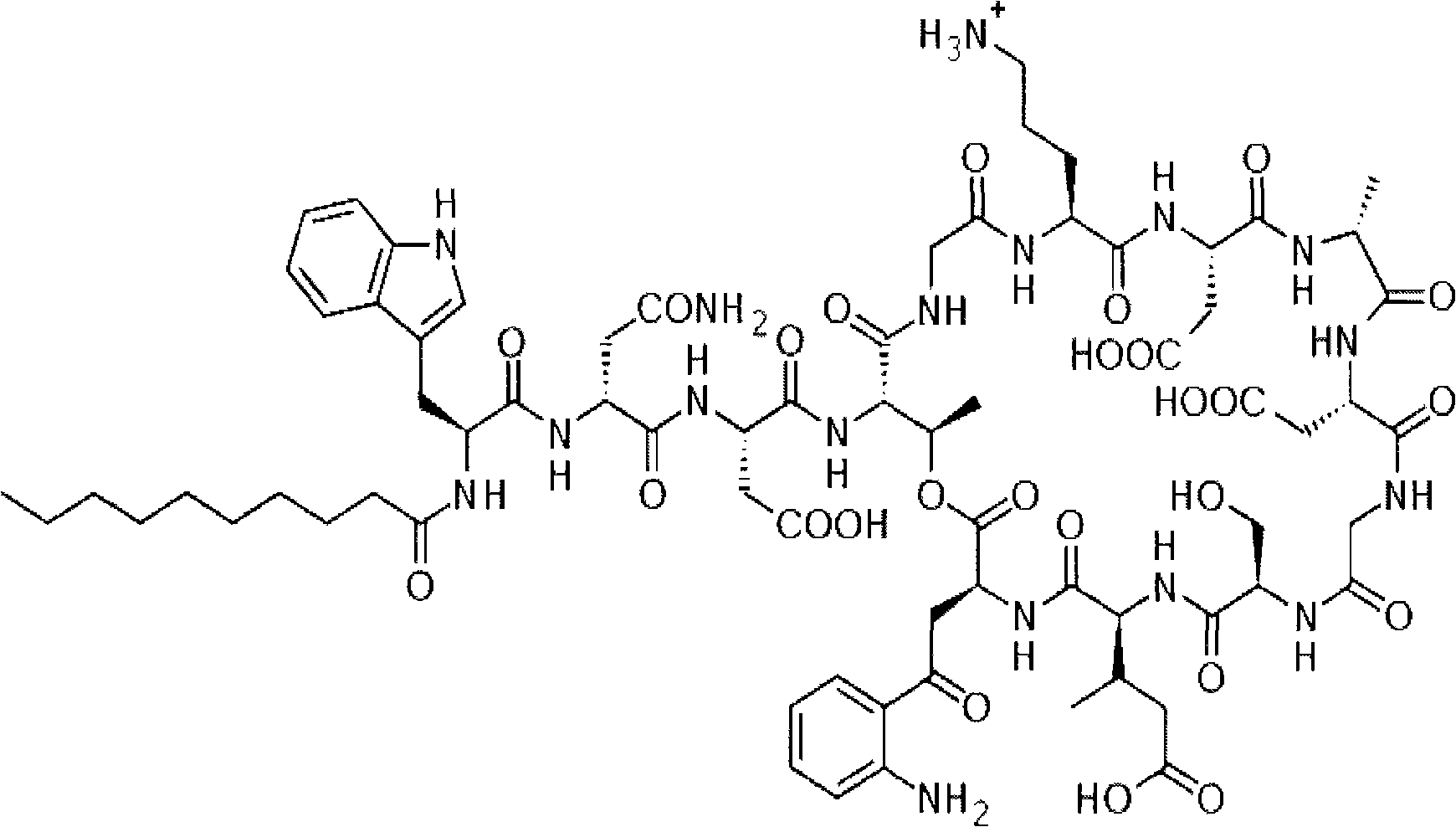

Image

Examples

Embodiment 1

[0078] 1. Preparation of amino acid solution:

[0079] Weigh amino acids with the following components and masses:

[0080] L-kynurenine: 3.67g, 3-methylglutamic acid: 2.86g, D-serine: 1.85g, D-alanine: 1.57g, L-ornithine: 2.33g, glycine: 2.65g , L-threonine: 2.10g, L-aspartic acid: 7.04g, L-asparagine: 2.33g, L-tryptophan: 3.60g; the total weight of the above amino acids is 30g.

[0081] Add the above-mentioned weighed amino acid into purified water, stir to dissolve it fully, and set the volume to 10L to obtain a compound amino acid aqueous solution with a concentration of 3.0g / L; sterilize the compound amino acid aqueous solution at 121°C for 15 minutes by high-pressure steam , cooled to obtain sterile compound amino acid aqueous solution.

[0082] 2. Fermentation and cultivation of Streptomyces roseospora NRRL11379 strain according to the following method:

[0083] The spores were inserted into 150 ml of seed medium, and the proportion of the medium was: vegetable prote...

Embodiment 2

[0090] 1. Preparation of amino acid solution:

[0091] The crude product of industrial compound amino acid contains the following amino acid composition and mass ratio:

[0092] Aspartic Acid: 7.28%, Threonine: 3.04%; Serine: 4.53%; Glutamic Acid: 8.01%; Glycine: 2.76%; Alanine: 2.54%; Cysteine: 0.79%; Valine: 2.63%; Methionine: 0.71%; Isoleucine: 1.72%; Leucine: 2.43%; Tyrosine: 0.52%; Phenylalanine: 1.35%; Lysine: 1.98%; Histidine: 1.35 %; Arginine: 5.32%; Proline: 4.01%. The total amount of amino acids is: 50.97%.

[0093] Weigh 110 g of the above-mentioned industrial compound amino acid crude product and add it into purified water, stir to make it fully dissolve, and set the volume to 10 L to obtain a compound amino acid aqueous solution with a concentration of 11.0 g / L; sterilize the compound amino acid aqueous solution at 121 ° C for 15 Minutes, cooled to obtain sterile compound amino acid aqueous solution.

[0094] 2. Fermentation and cultivation of Streptomyces ros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com