Processing agent composition for semiconductor surface and method for processing semiconductor surface using same

A composition and semiconductor technology, which can be used in the preparation of detergent mixture compositions, detergent compositions, chemical instruments and methods, etc., and can solve the problems of complicated procedures and difficulty in peeling off the anti-reflection film layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Embodiment 1 Preparation of semiconductor surface treatment agent composition (1) of the present invention

[0079] For a solution of 4.74 g of water and 1.29 g of sodium alkyl sulfosuccinate (Neocol P; manufactured by Daiichi Kogyo Pharmaceutical Co., Ltd.), under a yellow lamp (straight tube yellow fluorescent lamp, FLR40SY-IC / M; Mitsubishi Electric OSRAM Co., Ltd. 0.06 g of ammonium fluoride and 0.5 g of 2-benzyl-2-dimethylamino-1-(4-morpholinephenyl)-butanone-1 (Irgacure 369; manufactured by Ciba Seika Co., Ltd.) were added under the irradiation of g, stirred at room temperature. After confirming the dissolution of ammonium fluoride and Irgacure 369, the stirring was continued, 93 g of γ-butyrolactone was added to the solution, and 0.01 g of diethylhydroxylamine was added, followed by 0.4 g of citric acid to prepare a combination of the present invention at pH 2 thing (1).

Embodiment 2~18

[0080] Embodiments 2-18 Preparation of semiconductor surface treatment agent compositions (2)-(18) of the present invention

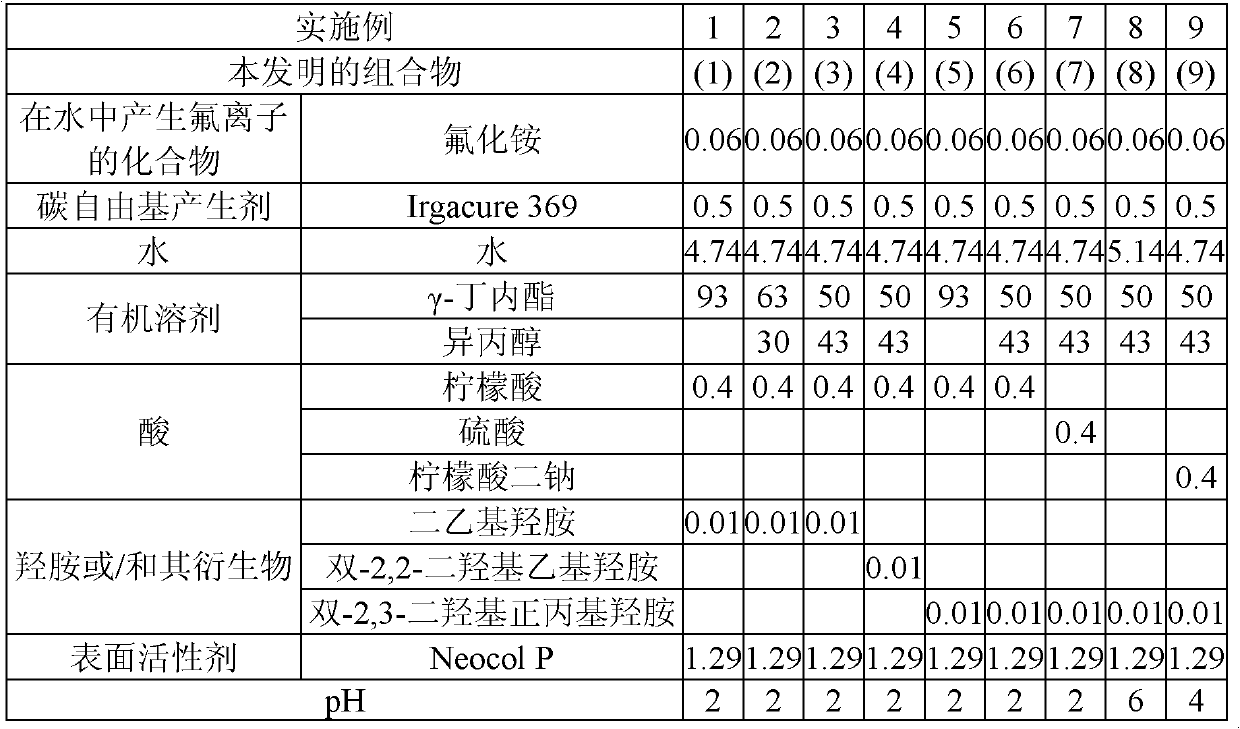

[0081] In Examples 2 to 18, compositions (2) to (18) of the present invention were prepared in the same manner as in Example 1, except that the components shown in Table 1 and Table 2 were used and the amounts shown in Table 1 and Table 2 were added. ). Their compositions are listed in Table 1 and Table 2 together with the composition of Example 1. In addition, the numerical value shown in Table 1 and Table 2 is the weight% density|concentration of each component when the total weight of a composition is assumed as 100%.

[0082] [Table 1]

[0083]

[0084] Irgacure 369: 2-Benzyl-2-dimethylamino-1-(4-morpholinephenyl)-butanone-1

[0085] Neocol P: sodium alkyl sulfosuccinate

[0086] [Table 2]

[0087]

[0088] Irgacure 369: 2-Benzyl-2-dimethylamino-1-(4-morpholinephenyl)-butanone-1

[0089] VA-057: 2,2'-Azobis[N-(2-carboxyethyl)-2-methylpro...

Embodiment 19

[0097] Example 19 Evaluation of the semiconductor surface treatment agent composition (1) of the present invention

[0098] For 50 mL of the composition (1) of the present invention prepared in Example 1, an ultraviolet irradiation device (UV irradiation device, MUV-35U MUV-PF001 with color filter; manufactured by Moritex Co., Ltd.) was used at room temperature with a center wavelength of 320 nm. The above-mentioned substrate sample for evaluation was immersed for 3 minutes under gentle stirring while irradiating with light. Thereafter, the substrate surface was rinsed with pure water for 30 seconds and dried with compressed air. As a result of observing the dried substrate sample visually and with a field emission scanning electron microscope (S-4800; manufactured by Hitachi High-Technologies Co., Ltd.), it was confirmed that the resist layer and the cured resist layer were well peeled off. There is no residue, and more than 90% of the anti-reflection film layer has been pee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com