Method for centrifugally removing harmful elements and impurities in iron-containing mixture

A technology of harmful elements and mixtures, applied in the field of metallurgy, can solve the problems of no harmful elements and impurities removed by centrifugation, strict requirements on raw material purity or impurity content, and high cost, so as to increase product profits, high product value, and increase efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

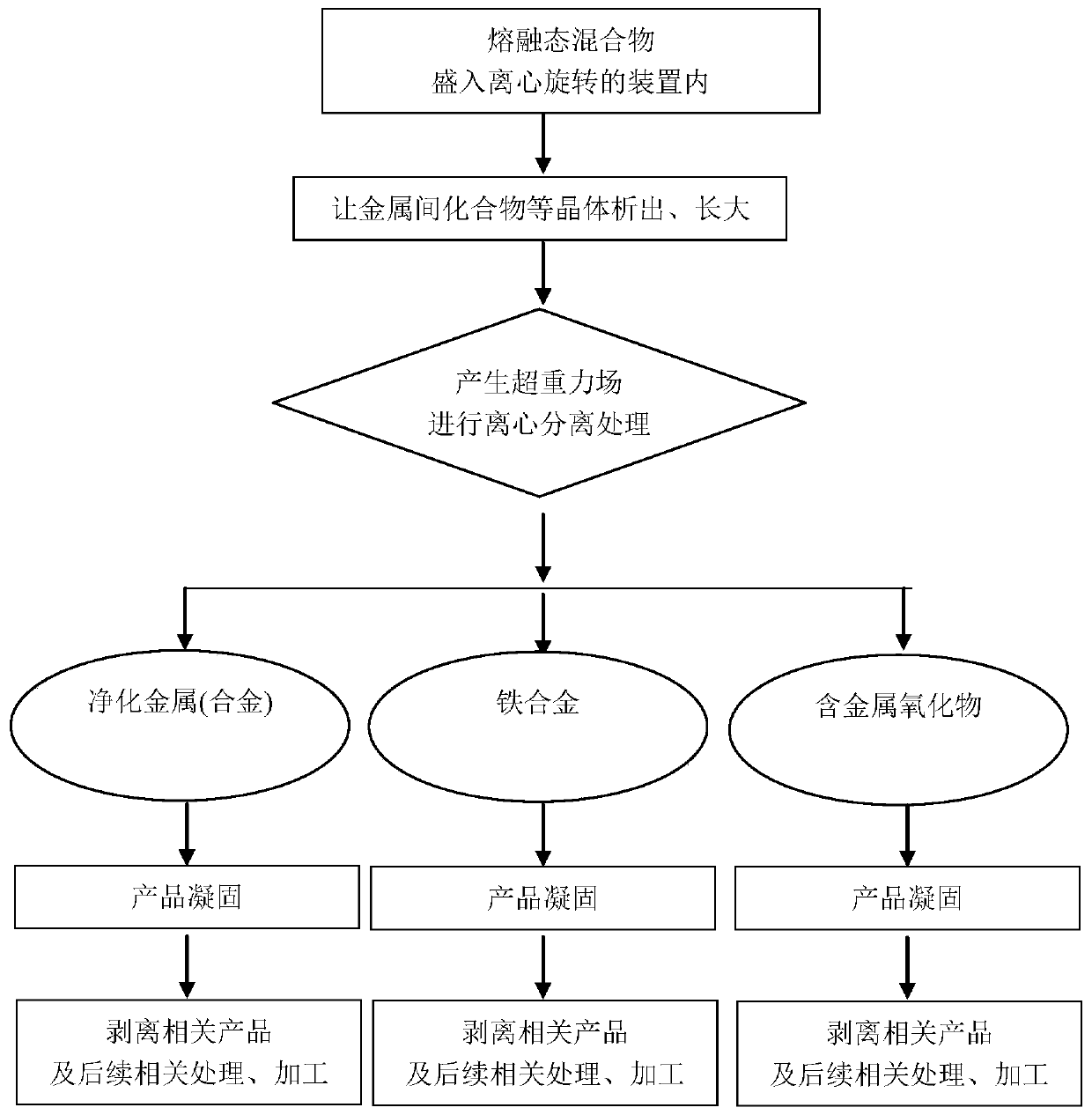

Image

Examples

Embodiment 1

[0030] A method for centrifugally removing harmful elements and impurities in iron-containing mixtures, the steps are:

[0031] ⑴Put 1000kg of molten mixture at 2400°C into a vertical centrifugal rotating device, in which the molten mixture contains 51% silicon, 42% aluminum, 4% iron, and 1.5% titanium, and the others contain Slag impurities, the inner wall of the vertical centrifugal rotating device is made of ceramic material.

[0032] (2) Completely place the molten mixture in the vertical centrifugal rotating device, control the cooling rate of the molten mixture to 30°C / min, and the centrifuge temperature to 2200°C to allow the solid phase compounds to precipitate and grow;

[0033] (3) Apply a supergravity centrifugal field to the molten mixture, the supergravity coefficient is 2500g, and gradually cool down to solidification; during the cooling process, the sedimentation and enrichment of the various substances of the compound in the periphery of the supergravity field,...

Embodiment 2

[0036] A method for centrifugally removing harmful elements and impurities in iron-containing mixtures, the steps are:

[0037] (1) A total of 200kg of molten mixture at 1700°C is put into a horizontal centrifugal rotating device, in which the molten mixture contains 61% of aluminum, 27% of silicon, 9% of iron, and 2.5% of titanium, and the others contain Slag impurities, the inner wall of the horizontal centrifugal rotating device is made of fire-resistant and heat-insulating materials.

[0038] ⑵The molten mixture is completely placed in the horizontal centrifugal rotating device, the cooling rate of the molten mixture is controlled to 5°C / min, and the centrifugation temperature is 1600°C, so that the solid phase compounds can precipitate and grow.

[0039] (3) Apply a supergravity centrifugal field to the molten mixture, and gradually cool down to solidification. During the cooling process, substances such as compounds settle and enrich on the periphery of the hypergravity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com