Hard carbon negative electrode material, its preparation method and application

A negative electrode material, hard carbon technology, applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of high cost, complicated preparation process, difficult industrial production, etc., and achieve low cost, good electrochemical performance, and stable product properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

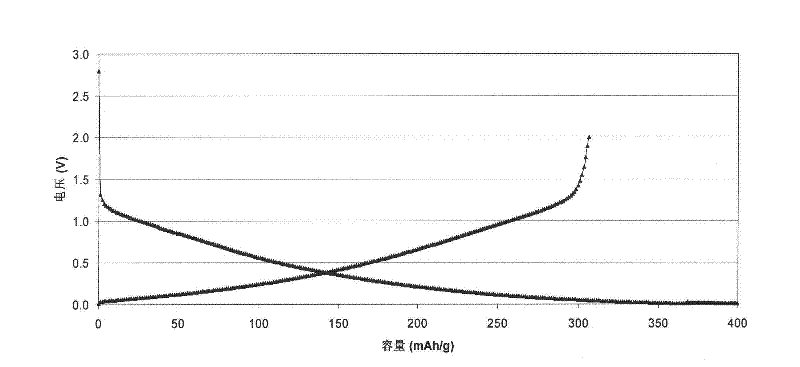

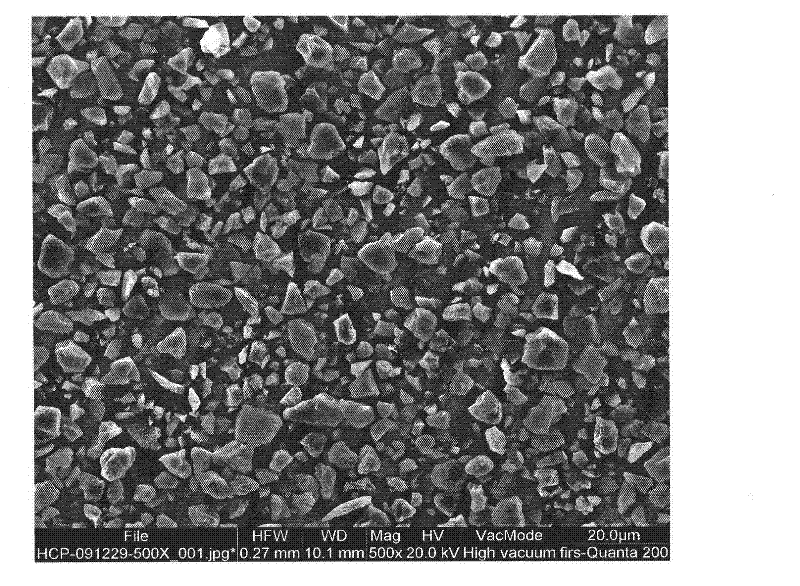

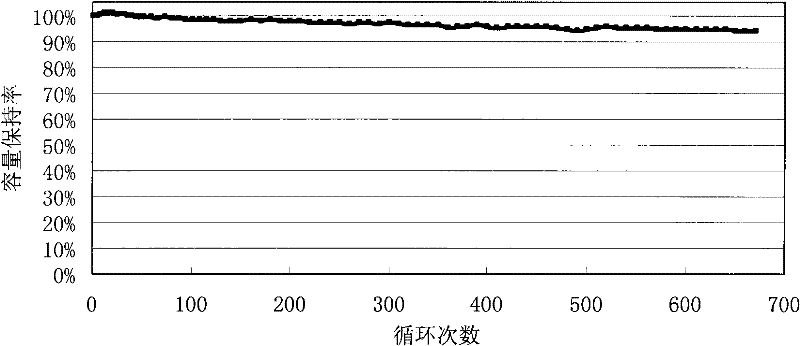

Embodiment 1

[0038] Crush the coal tar pitch to less than 0.1mm, add 100g of benzaldehyde, 50g of sulfuric acid and 1000g of the coal tar pitch powder into the reaction kettle under stirring and mix, raise the temperature to 200°C for cross-linking reaction and polymerization reaction for 5 hours to obtain cross-linking polymerization After the reaction, it was dissolved in 500g washing oil at 200°C for 2 hours, filtered hot, and the filtrate was vacuum-dried (-0.09~-0.1MPa, 150°C) for 2 hours, cooled to room temperature and discharged. 100-mesh sieve, put it into a well-type carbonization furnace, heat up to 600°C under the protection of nitrogen for pre-carbonization treatment for 2 hours, cool down to room temperature, and pass the crushed material through a 100-mesh sieve after being crushed, and put it in a pusher kiln under the protection of nitrogen Carry out carbonization treatment at 1000° C. for 2 hours to obtain a hard carbon negative electrode material. The first discharge capac...

Embodiment 2

[0040] Grind the coal tar pitch to below 0.1 mm, add 300 g of formaldehyde, 50 g of sulfuric acid and 1000 g of the coal tar pitch powder into the reaction kettle under stirring and mix, raise the temperature to 80°C for cross-linking reaction and polymerization reaction for 10 hours, after the reaction is completed, Dissolve 2000g of toluene at 100°C for 6 hours, heat filter, vacuum-dry the filtrate (-0.09~-0.1MPa, 150°C) for 2 hours, cool down to room temperature, and discharge the material. In the carbonization furnace, the temperature was raised to 400°C for 5 hours under the protection of nitrogen, and the temperature was lowered to room temperature. After crushing, the crushed material was passed through a 100-mesh sieve, and carbonization was carried out at 1000°C in a pusher kiln under the protection of nitrogen. 4 Hours, the hard carbon negative electrode material was prepared, the first discharge capacity of the half-cell was 296.4mAh / g, and the first discharge effici...

Embodiment 3

[0042]Crush the petroleum asphalt to less than 0.1mm, add 200g of paraformaldehyde, 100g of p-toluenesulfonic acid and 1000g of the petroleum asphalt powder into the reaction kettle alternately under stirring and mix, raise the temperature to 150°C for crosslinking reaction and polymerization reaction After 2 hours, dissolve in 1250g xylene at 150°C for 4 hours after the reaction, heat filter, vacuum-dry the filtrate (-0.09~-0.1MPa, 150°C) for 2 hours, cool down to room temperature and discharge, crush the crushed product Pass through a 100-mesh sieve, put it into a well-type carbonization furnace, raise the temperature to 500°C under the protection of nitrogen for pre-carbonization treatment for 4 hours, cool down to room temperature, and pass the crushed material through a 100-mesh sieve, and put it in a pusher kiln under the protection of nitrogen Carbonization treatment at 1600° C. for 2 hours yielded a hard carbon negative electrode material. The initial discharge capacity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com