Cellulose base/Fe3O4 composite adsorption material used for removing arsenic in water and preparation method thereof

A composite adsorption material, cellulose-based technology, used in water/sewage treatment, chemical instruments and methods, adsorbed water/sewage treatment, etc. Remove, easy to remove, easy to apply effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

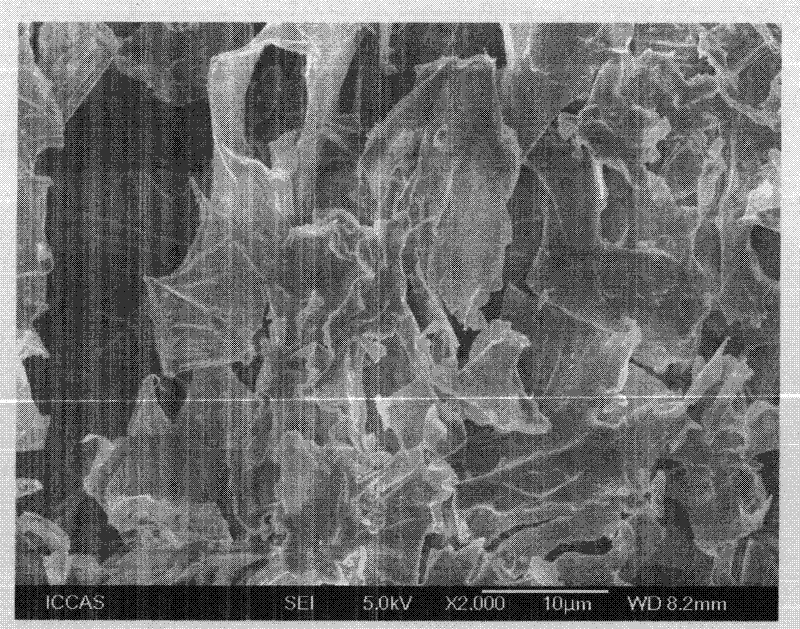

[0040] Using wheat straw as raw material mechanically pulverized wheat straw powder to prepare cellulose-based / Fe 3 o 4 (sample 1), and carry out the test of adsorption performance to sample 1

[0041] In a 100mL single-mouth bottle, add 0.5g of mechanical crushing to obtain a specific surface area of 0.1m 2 / g of wheat straw powder (the SEM photo of this wheat straw powder is shown in figure 1 ), and 50mLFeCl 3 / FeSO 4 Mixed aqueous solution (Fe 3+ with Fe 2+ The molar ratio is 2:1, the total concentration is 0.01mol / L), and 1 mL of ammonia water with a mass concentration of 25% is added under the protection of nitrogen to obtain a reaction system. The closed reaction system is reacted for 10 hours at 50 ° C. Precipitation method loads Fe on the surface of the wheat straw powder 3 o 4 Particles; after the reaction is over, the reaction product is repeatedly washed with water, magnetically separated, and vacuum-dried to obtain arsenic-free cellulose-based / Fe 3 o 4 ...

Embodiment 2

[0044] Using wheat straw as raw material mechanically pulverized wheat straw powder to prepare cellulose-based / Fe 3 o 4 (sample 2), and carry out the test of adsorption performance to sample 2

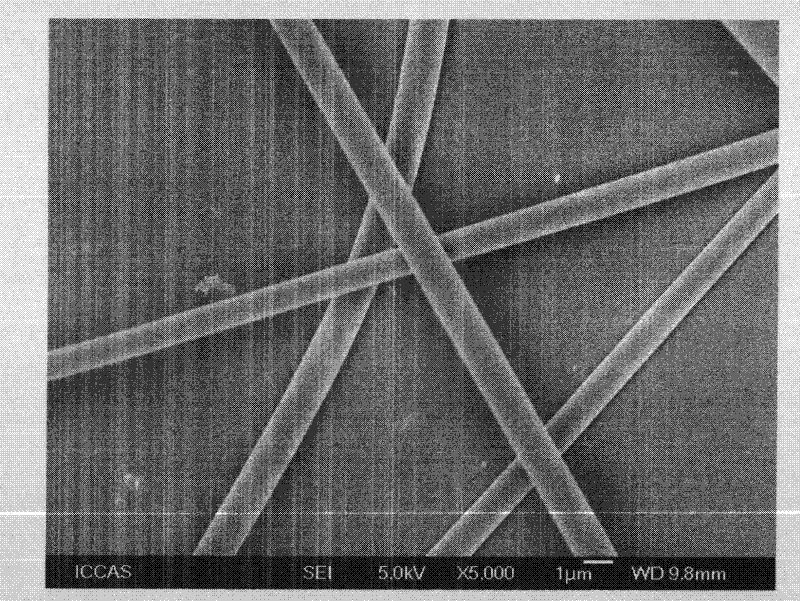

[0045] In a 100mL single-mouth bottle, add 0.5g of mechanical crushing to obtain a specific surface area of 10m 2 / g of wheat straw powder, and 50mLFeCl 3 / FeSO 4 Mixed aqueous solution (Fe 3+ with Fe 2+ The molar ratio is 2:1, the total concentration is 0.5mol / L), under the protection of nitrogen, add 10mL of ammonia water with a mass concentration of 25%, to obtain a reaction system, a closed reaction system, and react for 4 hours at 70 ° C. Precipitation method loads Fe on the surface of the wheat straw powder 3 o 4 Particles; after the reaction is over, the reaction product is repeatedly washed with water, magnetically separated, and vacuum-dried to obtain arsenic-free cellulose-based / Fe 3 o 4 Composite adsorbent material sample 2, the Fe 3 o 4 Granules make the cellul...

Embodiment 3

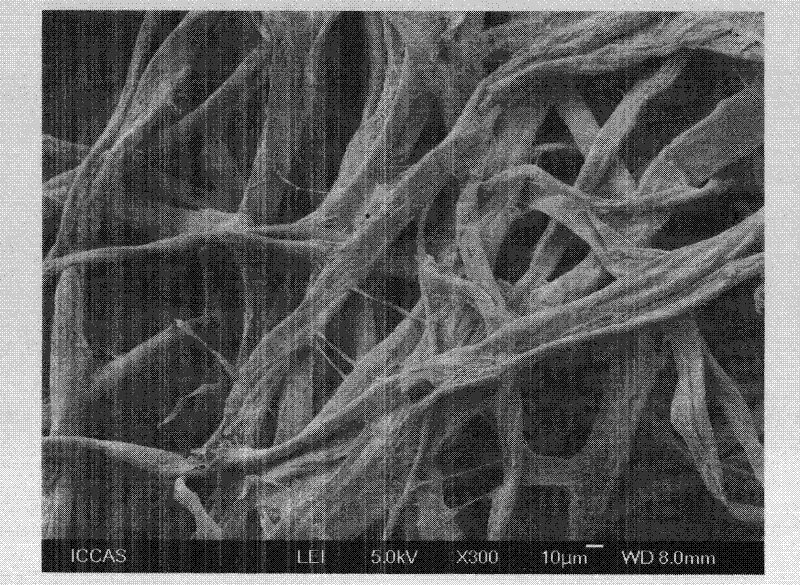

[0050] The cellulose fibers obtained after crushing the board prepared by using wood chips as raw materials were used to prepare the cellulose-based / Fe 3 o 4 (sample 3), and carry out the test of adsorption performance to sample 3

[0051] In a 100mL single-necked bottle, add 0.4g of mechanically pulverized cellulose fibers with a diameter of 10nm-100μm (see the SEM photo of the cellulose fibers in figure 2 ), and 50mLFeCl 3 / FeSO 4 Mixed aqueous solution (Fe 3+ with Fe 2+ The molar ratio is 2:1, and the total concentration is 1mol / L), under the protection of nitrogen, add 4mL of ammonia water with a mass concentration of 25%, to obtain a reaction system, close the reaction system, react for 24 hours at 20°C, and pass through in-situ co-precipitation method to load Fe on the surface of the cellulose fiber 3 o 4 Particles; after the reaction is over, the reaction product is repeatedly washed with water, magnetically separated, and vacuum-dried to obtain arsenic-free cel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com