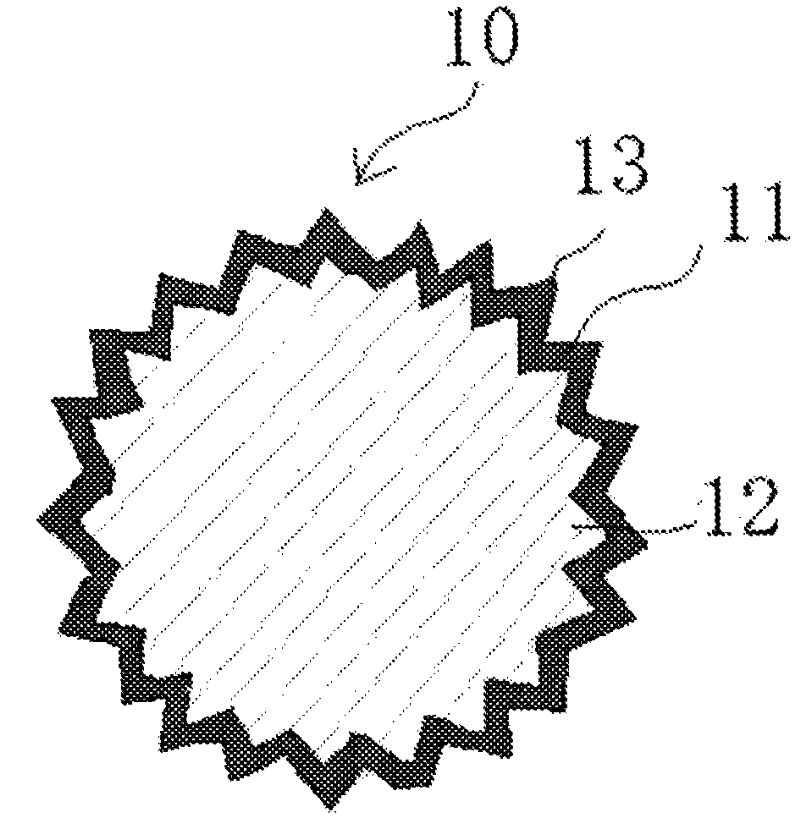

Conductive particles, anisotropic conductive film, assembly, and connection method

A conductive particle and anisotropic technology, applied in the direction of conductive adhesive connection, conductive connection, electrical component connection, etc., can solve the problems of indestructibility and low connection reliability, and achieve the goal of preventing agglutination and high connection reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0136] In Comparative Example 1, the production of the conductive particles was performed as follows, except that, in the same manner as in Comparative Example 1, the evaluation of the conductive particles, the production of the anisotropic conductive film, the production of the junction body 1, and the preparation of the junction body 1 were performed. Evaluation, preparation of the bonded body 2 , evaluation of the bonded body 2 , and observation of the presence or absence of indentations in the bonded body 2 . The results are shown in Tables 1, 3 and 4, Figure 4 middle.

[0137] (Production of conductive particles)

[0138] Put nickel particles with an absolute specific gravity of 8.9 and an average particle size of 5.0 μm (manufactured by Nikko-rica Corporation, trade name nickel powder 123) into an aqueous solution of thallium nitrate, and stir at a rate of 30 mL / min while heating to 60 ° C. Nickel plating is performed by adding a mixed solution of nickel sulfate, sodi...

Embodiment 2

[0140] In Example 1, changing the mixing ratio of nickel sulfate, sodium hypophosphite, sodium citrate, and thallium nitrate in the mixed solution is nickel-nickel particles formed by a nickel-plated layer with a phosphorus concentration of 2.3% by mass on the surface. B, except that, in the same manner as in Example 1, the evaluation of the conductive particles, the production of the anisotropic conductive film, the production of the bonded body 1, the evaluation of the bonded body 1, the preparation of the bonded body 2, and the preparation of the bonded body 2 were carried out. Evaluation. The results are shown in Tables 1, 3 and 4.

Embodiment 3

[0142] In Example 1, changing the mixing ratio of nickel sulfate, sodium hypophosphite, sodium citrate, and thallium nitrate in the mixed solution is nickel-nickel particles formed by a nickel-plated layer with a phosphorus concentration of 6.9% by mass. C, except that, in the same manner as in Example 1, the evaluation of the conductive particles, the production of the anisotropic conductive film, the production of the junction body 1, the evaluation of the junction body 1, the preparation of the junction body 2, and the preparation of the junction body 2 were carried out. Evaluation. The results are shown in Tables 1, 3 and 4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com