Chemically mechanical polishing solution

A technology of chemical machinery and polishing fluid, applied in the direction of polishing compositions containing abrasives, etc., can solve the problems of high price and high equipment requirements, and achieve the effect of good stability and long precipitation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

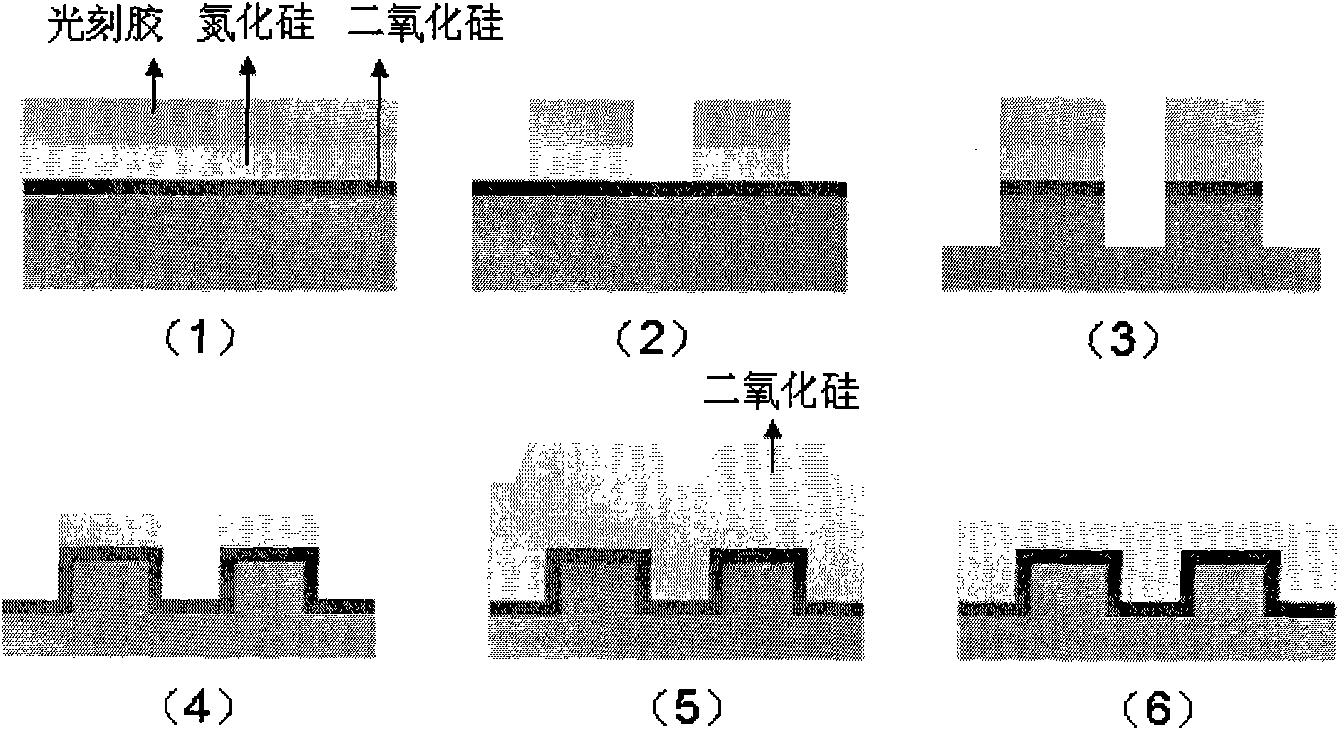

Method used

Image

Examples

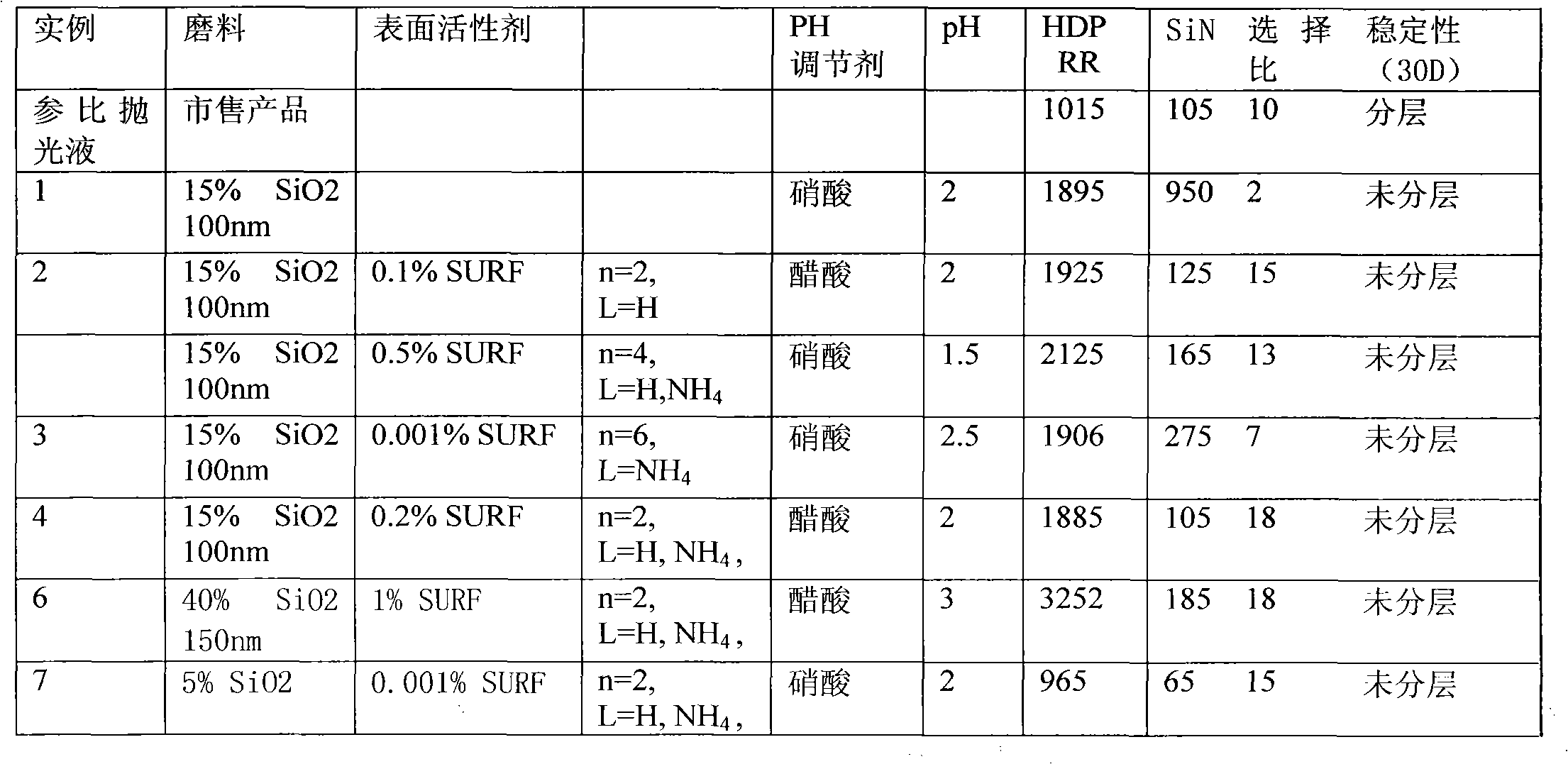

Embodiment 1~7

[0022]

[0023] SURF: CF 3 CF 2 (CF 2 CF 2 ) n CH 2 CH 2 SO 3 L, n=2-6, L=H, NH 4

[0024] As can be seen from the data in the table above, the abrasive particles of this patent have a higher HDP polishing rate and a higher silicon nitride rate. After adding a fluorine-containing surfactant, the removal rate of silicon nitride is greatly reduced, while HDP silicon dioxide has almost no effect, and the polishing selection ratio of the two is adjusted to 10-20, which is beneficial to eliminate the step height of silicon dioxide, realize planarization, and stop at the silicon nitride layer to form shallow trench isolation.

[0025] The polishing liquid of the invention has a higher HDP removal rate and a higher selectivity ratio to silicon nitride than the commercially available products, and the polishing liquid has a longer precipitation time than the commercially available products, better stability and low cost.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com