Antibacterial aging-resistant antistatic plastic master batch and preparation method thereof

An antistatic plastic, plastic masterbatch technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of non-compliance with hygienic standards, easy to age, not resistant to washing and service life, and achieve stable antibacterial and mildew resistance. The effect of pollution, aging resistance and weather resistance enhancement, flame retardant and fire resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

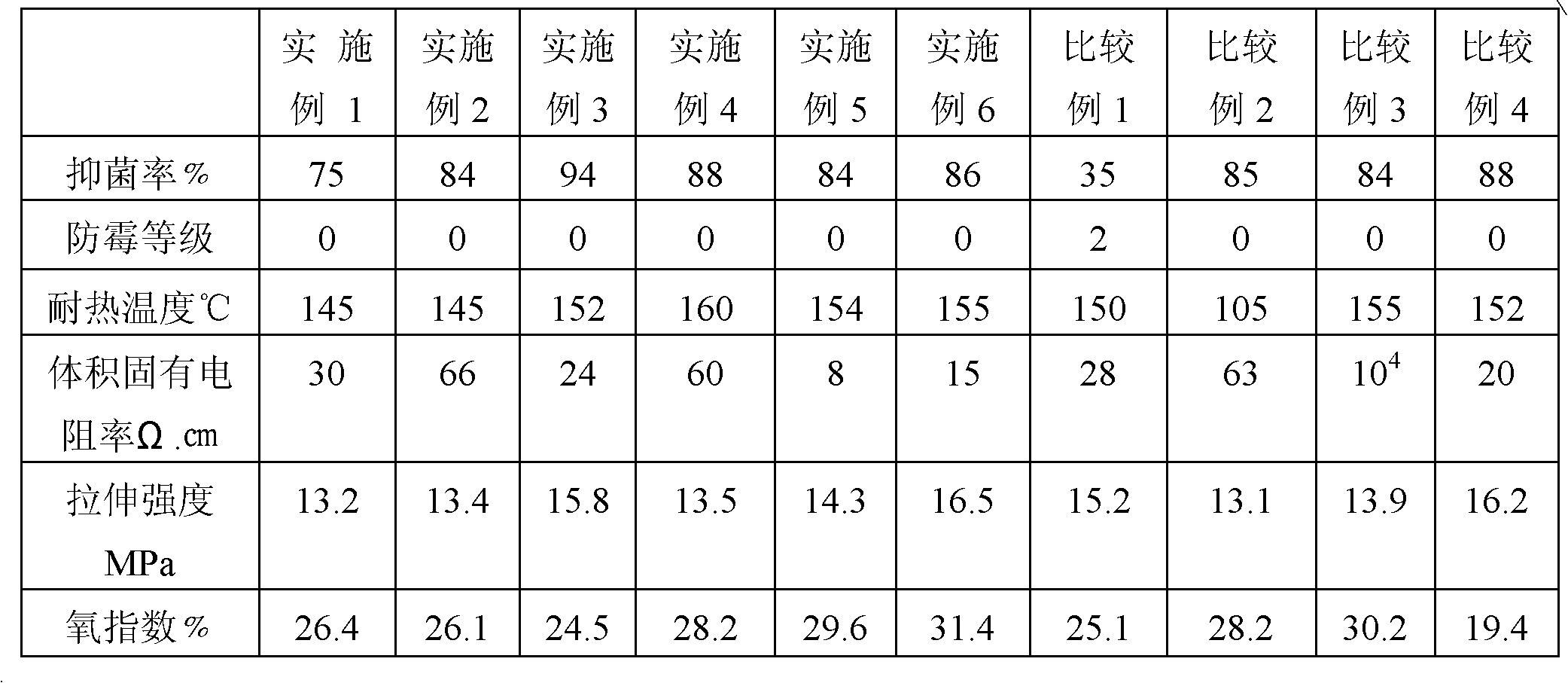

Examples

Embodiment 1

[0032] First put the base material consisting of 80 parts of low-density polyethylene and 20 parts of linear low-density polyethylene, 0.5 parts of stearic acid, 2 parts of oxidized polyethylene wax, 0.4 parts of coupling agent KR-9S, and 40 parts of conductive acetylene carbon black in the Mix in the mixer for 12 minutes; then 10 parts of copper powder (325 mesh), composite inorganic flame retardant (45 parts of aluminum hydroxide and 20 parts of zinc borate), 10103 parts of antioxidant, 6 parts of antioxidant DLTP, poly 25 parts of oxyethylene diamine biguanide salt and 6 parts of tris(1,2,2,6,6-pentamethylpiperidinium) phosphite were sequentially added and stirred for 8 minutes; then kneaded in a high-speed kneader for 6 minutes, The temperature of the material is 120°C, the speed of the kneader is 500-800r / min, and it is completely crushed; then it is extruded and granulated through a co-rotating and parallel twin-screw extruder, the diameter of the screw is (50-65) mm, and...

Embodiment 2

[0034]First put the base material consisting of 80 parts of low-density polyethylene and 20 parts of linear low-density polyethylene, 0.6 parts of stearic acid, 2 parts of oxidized polyethylene wax, 0.4 parts of coupling agent KR-9S, and 45 parts of conductive acetylene carbon black in the Mix in the agitator for 10 minutes; then compound inorganic flame retardant (50 parts of aluminum hydroxide and 20 parts of zinc borate), 10103 parts of antioxidant, 7 parts of antioxidant DLTP, 31 parts of polyoxyethylene diamine biguanide salt, Add 7 parts of tris(1,2,2,6,6-pentamethylpiperidinyl) phosphite in sequence and stir and mix for 8 minutes; then knead in a high-speed kneader for 8 minutes, the material temperature is 130°C, and the kneader speed is 500~800r / min, and completely pulverized; then extruded and granulated by co-rotating, parallel twin-screw extruder, the screw diameter is (50~65)mm, the aspect ratio (20~26): 1, and the screw speed is 60~80r / min. Processing conditions...

Embodiment 3

[0036] Firstly, base material consisting of 75 parts of low-density polyethylene and 25 parts of linear low-density polyethylene, 0.6 parts of stearic acid, 2 parts of oxidized polyethylene wax, 0.5 parts of coupling agent KR-9S, and 45 parts of conductive acetylene carbon black Mix in the mixer for 14 minutes; then 10 parts of copper powder (325 mesh), composite inorganic flame retardant (50 parts of aluminum hydroxide and 25 parts of zinc borate), 10104 parts of antioxidant, 7 parts of antioxidant DLTP, poly 40 parts of oxyethylene diamine biguanide salt and 7 parts of tris(1,2,2,6,6-pentamethylpiperidinium) phosphite were added in turn and stirred and mixed for 6 minutes; then kneaded in a high-speed kneader for 8 minutes, The temperature of the material is 110°C, the speed of the kneader is 500-800r / min, and it is completely pulverized; then it is extruded and granulated through a co-rotating and parallel twin-screw extruder with a screw diameter of (50-65) mm and an aspect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com