A kind of preparation method of rare earth modified regenerated cellulose fiber

A technology of regenerated cellulose and rare earth modification, applied in the direction of man-made filament made of viscose, can solve the problems of non-degradable environmental pollution and achieve the effect of rare earth stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

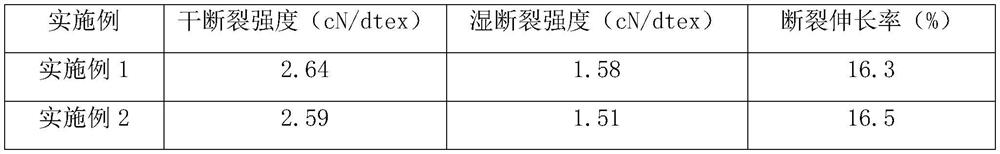

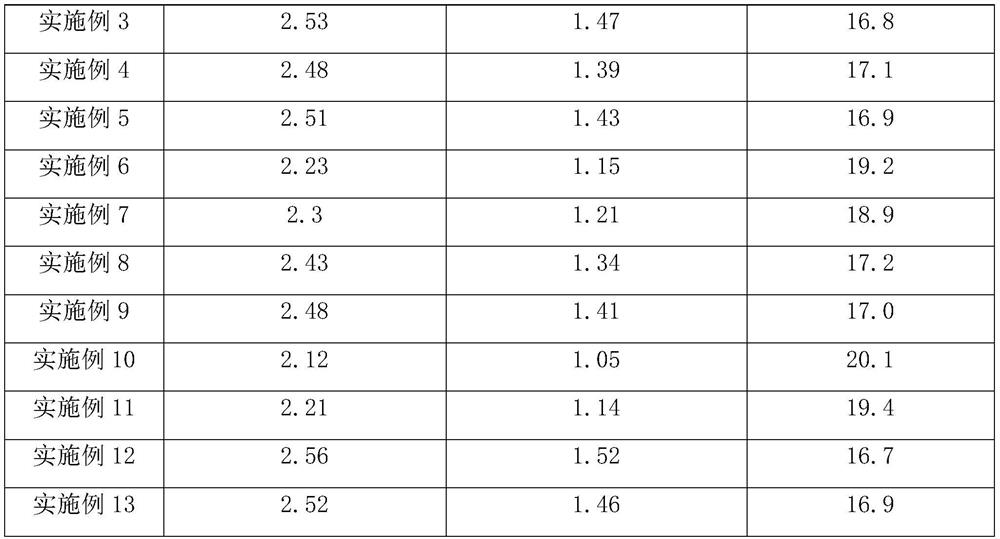

Examples

Embodiment 1

[0056] Embodiment 1 A preparation method of rare earth modified regenerated cellulose fiber, comprising the following steps:

[0057] 1. Preparation of rare earth modified functional additives

[0058] (1) Preparation of rare earth chlorides

[0059] Dissolve lanthanum oxide in hydrochloric acid, sonicate at 37°C for 15min, ultrasonic frequency 160KHZ, the concentration of hydrochloric acid is 5mol / L, and the addition amount is 180% of lanthanum oxide; after the dissolution is complete, evaporate and concentrate at 60°C, and crystallize to obtain chloride lanthanum.

[0060] (2) Oxidation

[0061] Grind the chitosan into powder, put it in the 5% glacial acetic acid solution according to the ratio of 1:17, stir at 65 ° C for 70min, the stirring speed is 700r / min, and then add the 2% NaOH solution to stir 18min, the chitosan solution was obtained after the chitosan was completely swollen;

[0062] The added amount of the NaOH solution is 6 times that of chitosan.

[0063] P...

Embodiment 2

[0089] Embodiment 2 A preparation method of rare earth modified regenerated cellulose fiber, comprising the following steps:

[0090] The difference between this example and Example 1 is that the preparation of rare earth chloride and the oxidation steps are different, and the remaining steps are consistent with Example 1, as follows:

[0091] (1) Preparation of rare earth chlorides

[0092] Dissolve lanthanum oxide in hydrochloric acid, sonicate at 35°C for 20min, ultrasonic frequency 150KHZ, the concentration of hydrochloric acid is 6mol / L, and the amount added is 150% of lanthanum oxide; after the dissolution is complete, evaporate and concentrate at 55°C, and crystallize to obtain chloride lanthanum.

[0093] (2) Oxidation

[0094] Grind the chitosan into powder, put it in a 4% glacial acetic acid solution in a ratio of 1:15, stir at 60 °C for 60 min, and the stirring rate is 600 r / min, and then add a mass fraction of 1% NaOH solution to stir For 15min, the chitosan sol...

Embodiment 3

[0098] Embodiment 3 A preparation method of rare earth modified regenerated cellulose fiber, comprising the following steps:

[0099] The difference between this example and Example 1-2 is that the preparation of rare earth chloride and the oxidation steps are different, and the remaining steps are the same as those of Example 1-2, as follows:

[0100] (1) Preparation of rare earth chlorides

[0101] Dissolve lanthanum oxide in hydrochloric acid, sonicate at 40°C for 10 min, ultrasonic frequency 180KHZ, the concentration of hydrochloric acid is 4mol / L, and the addition amount is 200% of lanthanum oxide; after the dissolution is complete, evaporate and concentrate at 65°C, and crystallize to obtain chloride lanthanum.

[0102] (2) Oxidation

[0103] Grind the chitosan into powder, put it in a 6% glacial acetic acid solution at a ratio of 1:20, stir at 70°C for 80 minutes, and the stirring speed is 800r / min, and then add a 1% NaOH solution to stir. 20min, the chitosan solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com