Method for synthesizing cyclic carbonate ester in micro reactor system

A technology of cyclic carbonates and microreactors, applied in chemical instruments and methods, organic chemistry methods, formation/introduction of functional groups, etc., can solve the problem of low catalyst system activity, poor heat and mass transfer performance, and difficult process control and other issues, to achieve the effect of improving energy utilization, operating flexibility, and shortening response time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

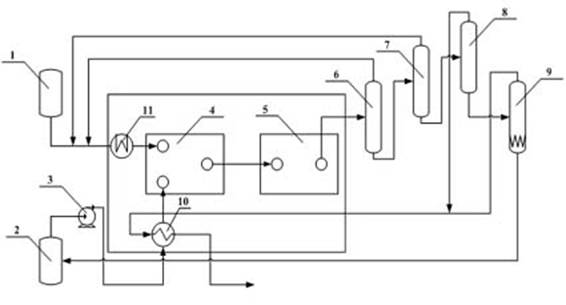

[0018] For the reaction process, see figure 1 . The microreactor system consists of a preheater 11 , a micromixer 4 , a microchannel reactor 5 and a microheat exchanger 10 . The inner channel of the micro-mixer 4 adopts the interdigitated T-shaped mixing method, and the channel is a square channel of 300 μm×300 μm, that is, the equivalent diameter is 300 μm; the length of the channel in the micro-channel reactor 5 is 300 mm, and the equivalent diameter is 300 μm.

[0019] The microreactor system specifically includes a storage tank 1 containing carbon dioxide gas, a storage tank 2 for the reaction raw material liquid, a high-pressure metering pump 3; a micromixer 4, a microchannel reactor 5, a gas-liquid separation tank 6, a first-stage flash Steam tank 7, second stage flash tank 8, vacuum distillation tower 9, microchannel heat exchanger 10, preheater 11;

[0020] The storage tank 1 of carbon dioxide gas is connected to one inlet of the micro-mixer 4 through a preheater 11 ...

Embodiment 2~8

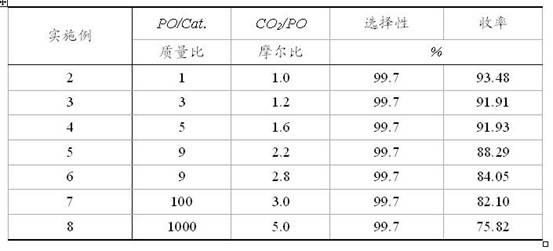

[0024] The reaction process is described with reference to Example 1. Change the concentration of key reaction materials in the process, that is, change the molar ratio of carbon dioxide to propylene oxide (denoted as, CO 2 / PO), and the mass ratio of propylene oxide and 1-ethanol-3-methylimidazolium bromide (recorded as PO / Cat.), at the same reaction temperature, reaction pressure and material residence time conditions as in Example 1 Next, in the microreactor system, carry out the ring closure synthesis reaction, the selectivity of the obtained target product propylene carbonate ( Selectivity ) and yield ( Yield ) are listed in the table below:

[0025]

Embodiment 9

[0027] The reaction process is described with reference to Example 1. The concentration of the key reactant material in the fixed process, i.e. the molar ratio of carbon dioxide to propylene oxide (CO 2 / PO) is 1.4, and the mass ratio of propylene oxide to 1-ethanol-3-methylimidazolium bromide (PO / Cat.) is 9, and the residence time of the reaction materials in the micro-mixer and microchannel reactor is 60 seconds, reaction pressure 3.5MPa, synthesis of propylene carbonate under the conditions of reaction temperature 100°C, 140°C, 160°C, 220°C, the one-pass yield of the target product propylene carbonate under the corresponding conditions were 35.62%, 53.84%, 79.58% %, 68.74%, the selectivity is greater than 99.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com