Catalyst for synthesizing isopropenyl acetate and preparation method thereof

A technology of propylene acetate and catalyst, applied in the field of catalyst and preparation thereof, can solve the problems of high initial activity of catalyst, loss of catalyst yield, shortening of catalyst acclimation period, etc., and achieve the effect of reducing energy consumption and material consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

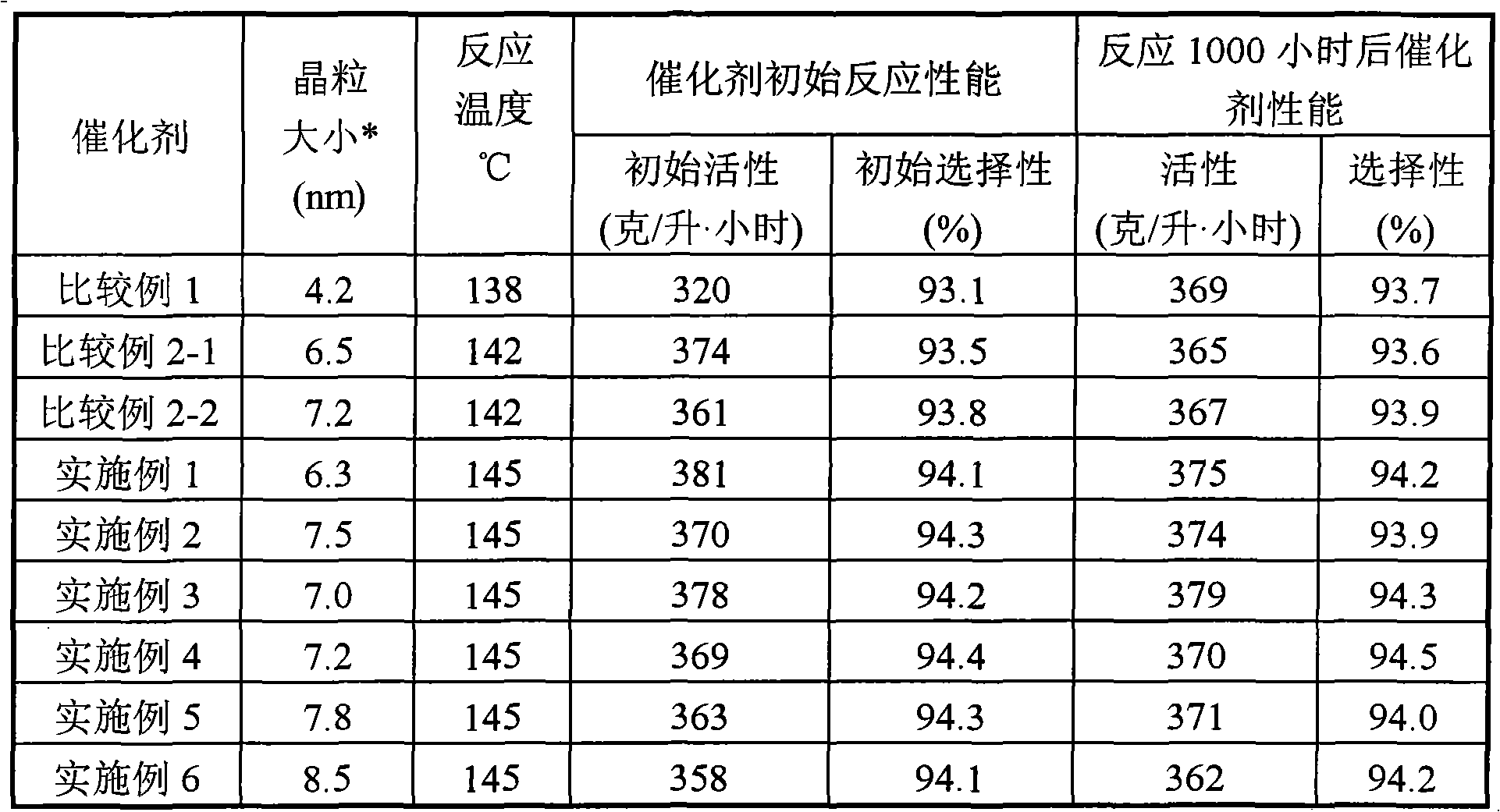

Examples

Embodiment 1

[0041] Prepare 5% palladium in H 2 PdCl 4 Solution 66 g and 5% copper in CuCl 215 grams of the solution was diluted to 1000 milliliters with deionized water, and 1100 milliliters of a spherical silica carrier (particle size 4-6 mm) was taken and immersed for 1 hour at room temperature to prepare a catalyst precursor.

[0042] 27.5 g of sodium silicate nonahydrate was made into 100 ml of aqueous solution and added to the catalyst precursor, shaken several times to avoid agglomeration, and then stood still for 24 hours.

[0043] The catalyst precursor was impregnated with 85wt% hydrazine hydrate 30ml for reduction, and the impregnation time was 5 hours. The catalyst precursor was washed with deionized water until the effluent did not contain chloride ions (tested with silver nitrate), and then dried at 60°C.

[0044] The catalyst precursor was calcined under a nitrogen / acetic acid atmosphere with acetic acid partial pressure at 5% of the total pressure. The calcination tempe...

Embodiment 2

[0048] The catalyst precursor was calcined under an air / acetic acid atmosphere, wherein the partial pressure of acetic acid accounted for 20% of the total pressure, and the rest were the same as in Example 1.

Embodiment 3

[0050] The catalyst precursor was calcined under an air / acetic acid atmosphere with acetic acid partial pressure of 20% of the total pressure. Calcining temperature is 300 ℃, and calcining time is 5 hours, all the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com