Coiled membrane separating technology and equipment with forward feeding and reversed washing processes

A technology of separation equipment and roll-type membrane, which is applied in the direction of semi-permeable membrane separation, membrane technology, chemical instruments and methods, etc. It can solve the problems of accelerating the replacement frequency, difficult to restore the membrane, and increasing the operating cost of the membrane system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

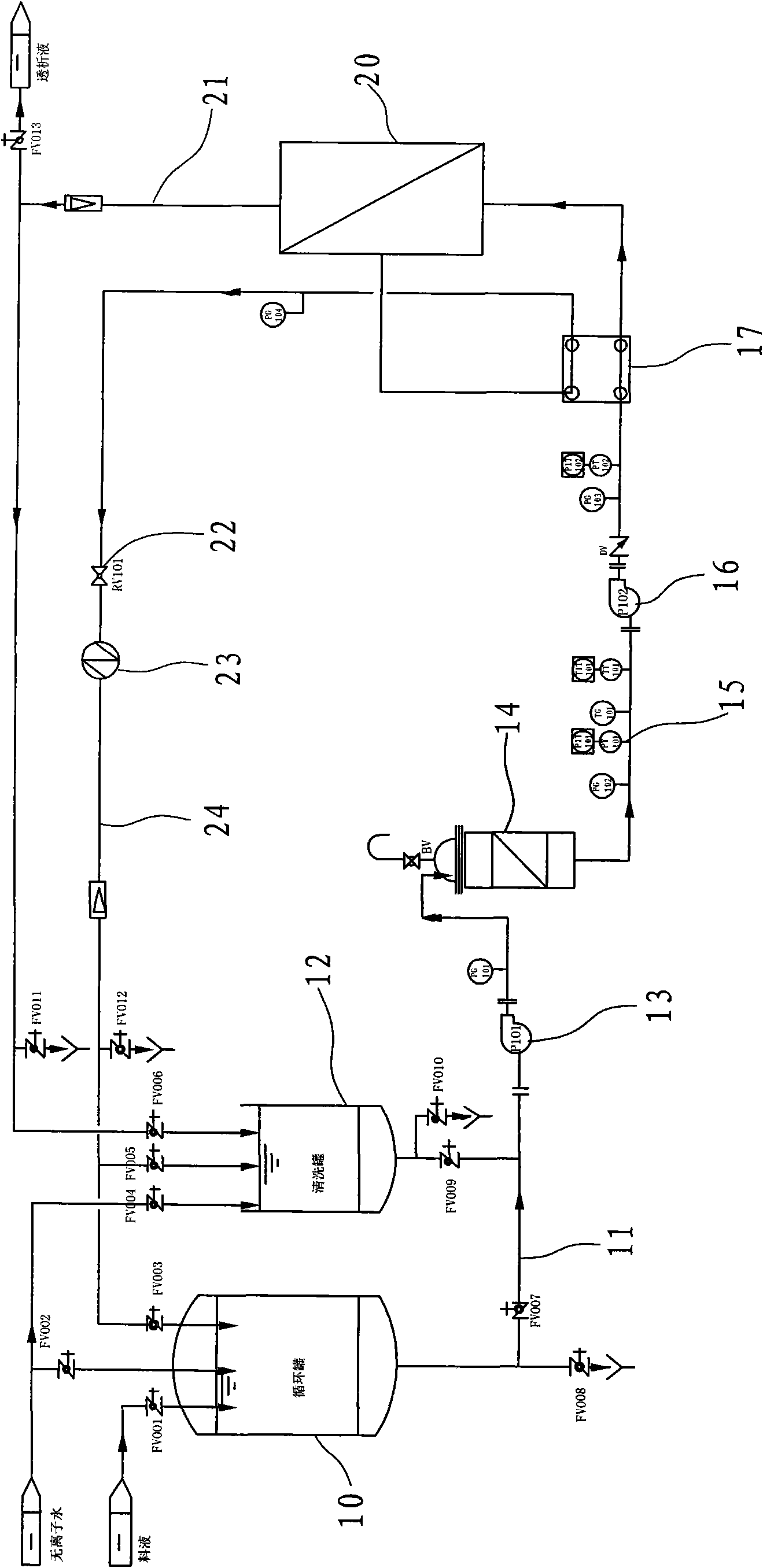

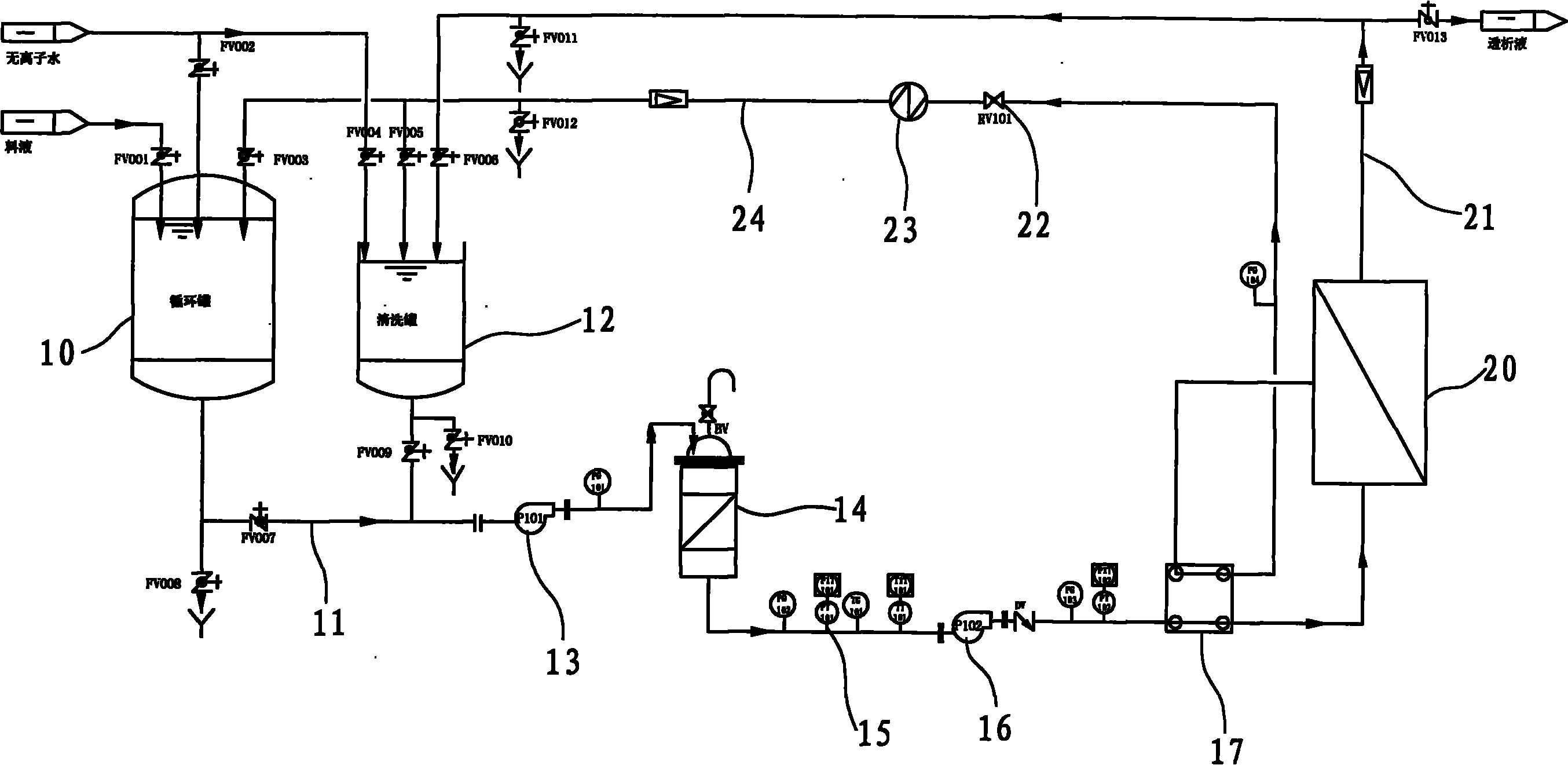

[0033] Such as figure 1 As shown, the present invention discloses a roll-type membrane separation device with forward feeding and reverse flow cleaning, including a circulation tank 10, a cleaning tank 12, a feeding pump 13, a high-pressure pump 16, a membrane stack 20 and a shut-off valve 22 . The inlet liquid pipe of the circulation tank 10, the outlet is connected to the feed end of the membrane stack 20 through the pipeline 11, the feed pump 13 and the high pressure pump 16, and the discharge end of the membrane stack 20 is connected back through the concentration pipe 24 and the stop valve 22 The circulation tank 10 and the dialysis end of the membrane stack 20 are connected to a dialysis pipeline 21 . In this embodiment, a security filter 14 and a pressure sensor 15 are connected between the feeding pump 13 and the high-pressure pump 16 . The membrane elements of the membrane stack 20 are connected to the switch plate 17, and the switch plate 17 is used to conveniently...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com