Composite nano porous electrode material, process for production thereof, and lithium ion secondary battery

An electrode material and nanoporous technology, which is used in the manufacture of composite nanoporous electrode materials and in the field of lithium ion secondary batteries, can solve the problems of poor electron conductivity and poor diffusion of Li ions and cannot exert performance, and achieves improved electron conductivity, The effect of increased insertion and disengagement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

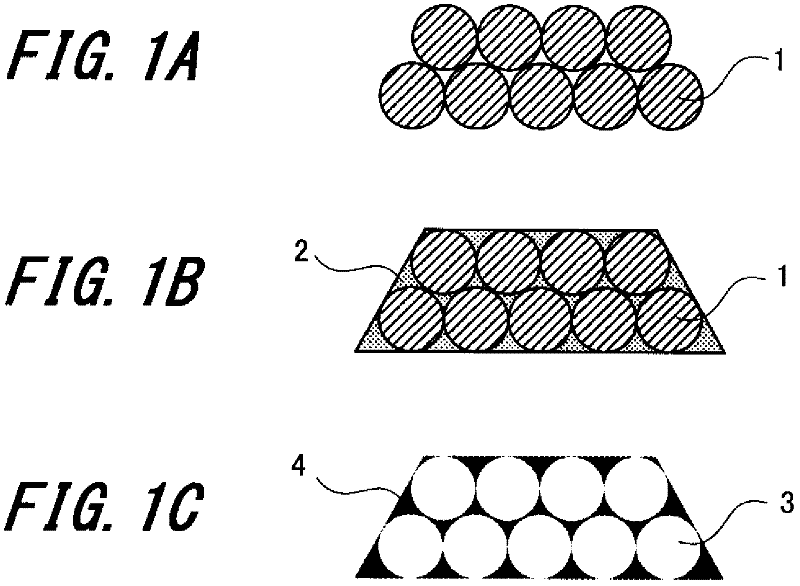

[0036] Below, refer to Figure 1 to Figure 12 , the composite nanoporous electrode material and its manufacturing method according to the first embodiment of the present invention will be described.

[0037] [Structure of Composite Nanoporous Electrode Material]

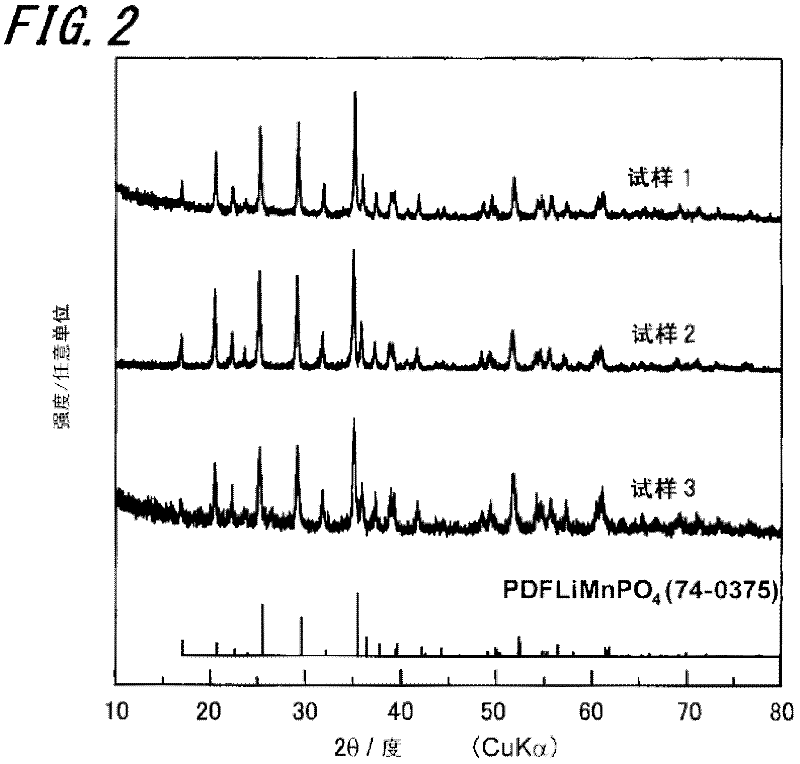

[0038] First, the structure and characteristics of the composite nanoporous electrode material of the present embodiment will be described. The composite nanoporous electrode material of this embodiment example has a porous structure in which nanometer-sized pores are connected in a three-dimensional manner, and its pore walls are made of olivine-type LiMnPO 4 and carbon formation. In addition, its specific surface area Sa is 55m 2 g -1 2 g -1 , the carbon content Cc is 15.5wt%<Cc<28wt%, and the crystallite diameter is less than 39nm.

[0039] Hereinafter, the manufacturing method of the composite nanoporous electrode material of this embodiment example is demonstrated.

[0040] [Manufacturing method of compos...

Embodiment

[0052] First, a colloidal dispersion liquid composed of polystyrene particles having a particle diameter of 200 nm was centrifuged to produce colloidal crystals composed of polystyrene particles. Then, the polystyrene pellets were dried under reduced pressure to obtain polystyrene pellets as molds.

[0053] On the other hand, water and ethanol were mixed to prepare a mixed solution having an ethanol concentration of 20 wt%. Next, the LiNO 3 , Mn(NO 3 ) 2 ·6H 2 O, NH 4 h 2 PO 4 Dissolve in this mixed solution so that each concentration becomes 0.5 mol / L, and further add sucrose so that the concentration becomes 1 mol / L to adjust the precursor solution. That is, the number of moles of sucrose is adjusted so that the number of moles of sucrose becomes twice the concentration of the number of moles of Mn in the precursor solution.

[0054] Next, the dried polystyrene particles are immersed in the precursor solution for 5 to 7 days, and the spaces of the polystyrene particl...

no. 2 Embodiment approach

[0112] [Lithium ion secondary battery]

[0113] Figure 14 A schematic configuration diagram of a lithium ion secondary battery according to a second embodiment of the present invention is shown in . The lithium ion secondary battery 10 of this embodiment example is an example in which the composite nanoporous electrode material of the first embodiment is used as a positive electrode active material.

[0114] The lithium ion secondary battery 10 of the present embodiment includes a cylindrical case 16 made of nickel, a roll body 20 housed in the case 16 , and a non-aqueous electrolytic solution housed in the case 16 as well.

[0115] A positive terminal 17 is formed on the upper bottom of the casing 16 . In addition, although not shown, a negative electrode terminal is formed on the lower bottom of the casing 16 .

[0116] The roll body 20 has a structure in which a strip-shaped positive electrode member 12 , a separator 11 , and a negative electrode member 13 are sequentia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Crystallite diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com