Heat-activatable free-radical initiators and composite material which comprises magnetic particles

A technology of composite materials and initiators, applied in the direction of silver compounds, silver compounds, iron compounds, etc., can solve the problems of uneconomical energy input, heating, affecting properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] Example 1 : One stream consists of SiCl containing 0.49kg / h 4 and 0.05kg / h of monosilane in vapor form, the second stream of the aerosol form obtained at room temperature (23° C.) by a two-fluid nozzle is composed of a 25% by weight concentration of ferrous (II) chloride in water ( Equivalent to 1.55kg / h of ferrous (II) chloride) and 5Nm 3 / h of nitrogen as spray gas, the two streams are introduced separately into the mixing zone of the reactor. This mixture is ignited in the combustion zone of the reactor by 7.9Nm 3 / h of hydrogen and 21Nm 3 / h of the air mixture produced by the flame reaction. The residence time of the reaction mixture in the combustion zone is about 40 ms.

[0092] In the cooling zone following the combustion zone, the reaction mixture was cooled to 332° C. by introducing 8 kg / h of water.

[0093] The resulting solids are separated from the gaseous substances on a filter.

Embodiment 2

[0094] Example 2 Same as Example 1, except that the proportions of silicon tetrachloride, monosilane, hydrogen and air were changed.

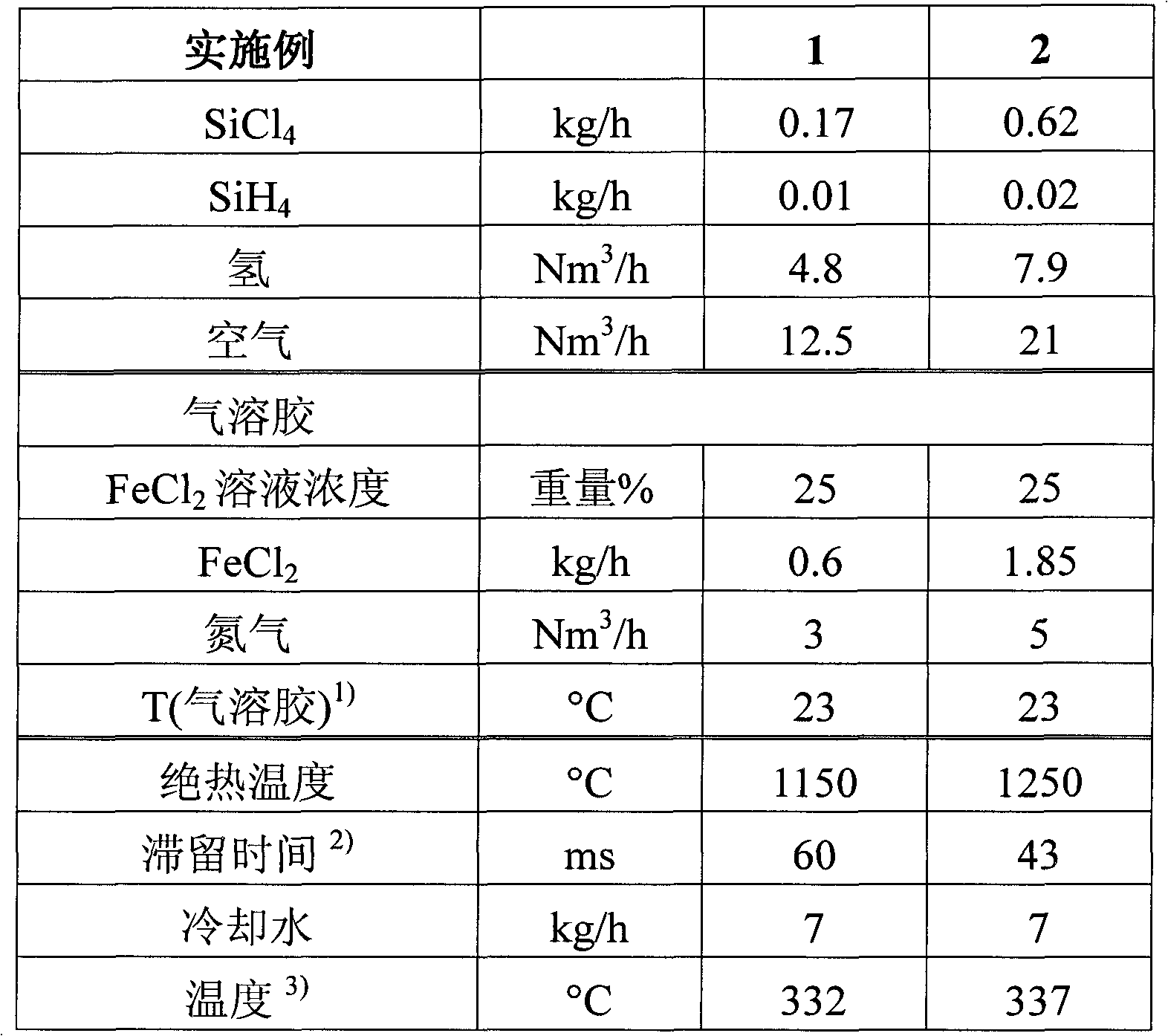

[0095] Table 1 gives the reaction parameters of Examples 1 and 2, and Table 2 gives the physicochemical data of the powders obtained.

[0096] Table 1: Reaction parameters

[0097]

[0098] 1) when entering the mixing zone; 2) in the combustion zone; 3) after cooling;

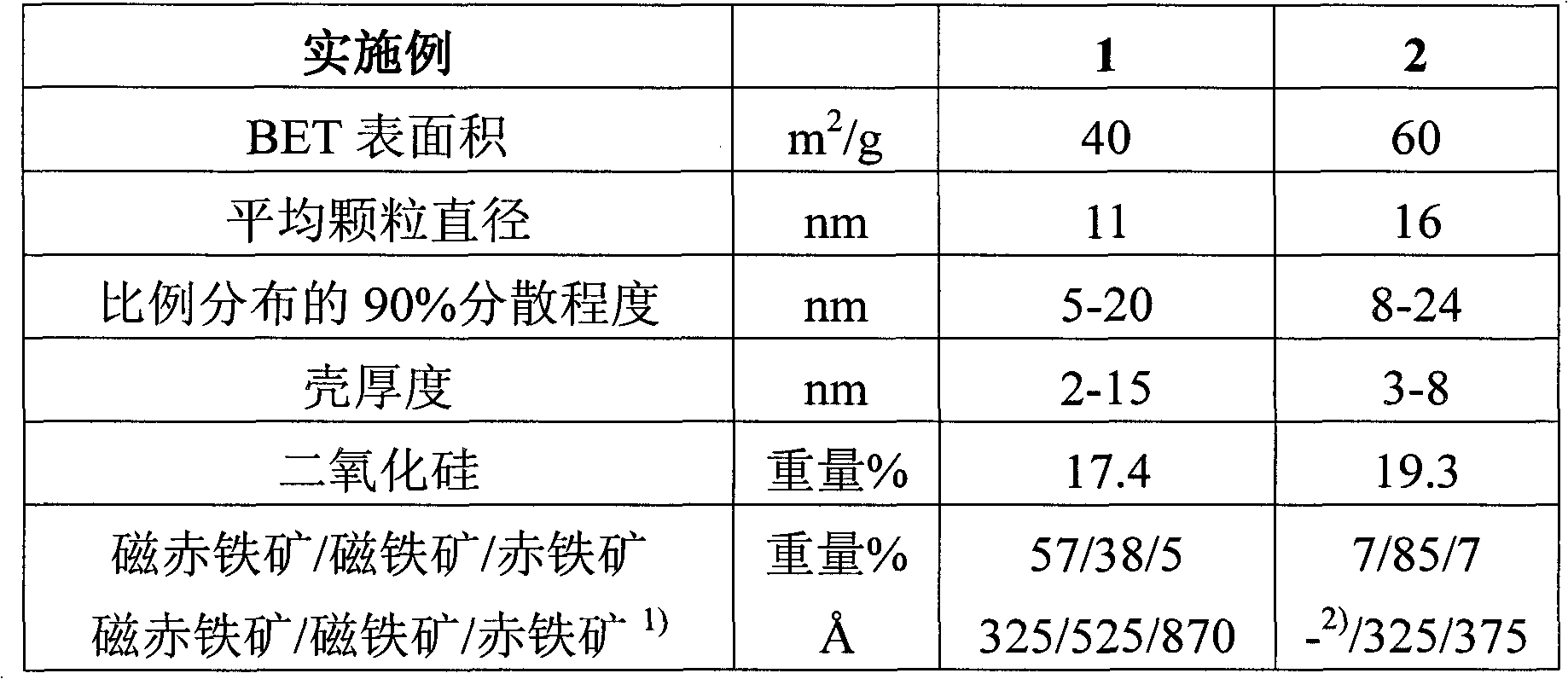

[0099] Table 2: Physicochemical data of powders

[0100]

[0101] 1) Magnetite, hematite ± 5%; maghemite ± 10%;

[0102] 2) The crystallite size cannot be determined due to the low proportion of maghemite.

[0103] peroxide:

[0104] Dicumyl peroxide (DCUP, CAS 80-43-3) in crystalline form, considered technically pure.

[0105] 2,5-Dimethyl-2,5-bis(tert-butylperoxy)hex-3-yne (DYBP-85-WO, CAS 1068-27-5), in desensitized form at 75 % content exists in white oil.

[0106]2,4-Dichlorobenzoyl peroxide (DCLBP-50-PSI, CAS 133-14-2), crystalline peroxide desensitized in...

Embodiment 3

[0111] Example 3 : 100 g of tert-butyl peroxybenzoate (liquid component) and 100 g of the granulate from example 1 were mixed in a paddle mixer (Beken kneader) for 20 min to obtain a dry flowable, dust-free composite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com