Composite light guiding film module

A technology of light guide film and light, which is applied in the direction of light guide, optics, optical components, etc., and can solve the problems of high cost, light coupling into the film, light source into the film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

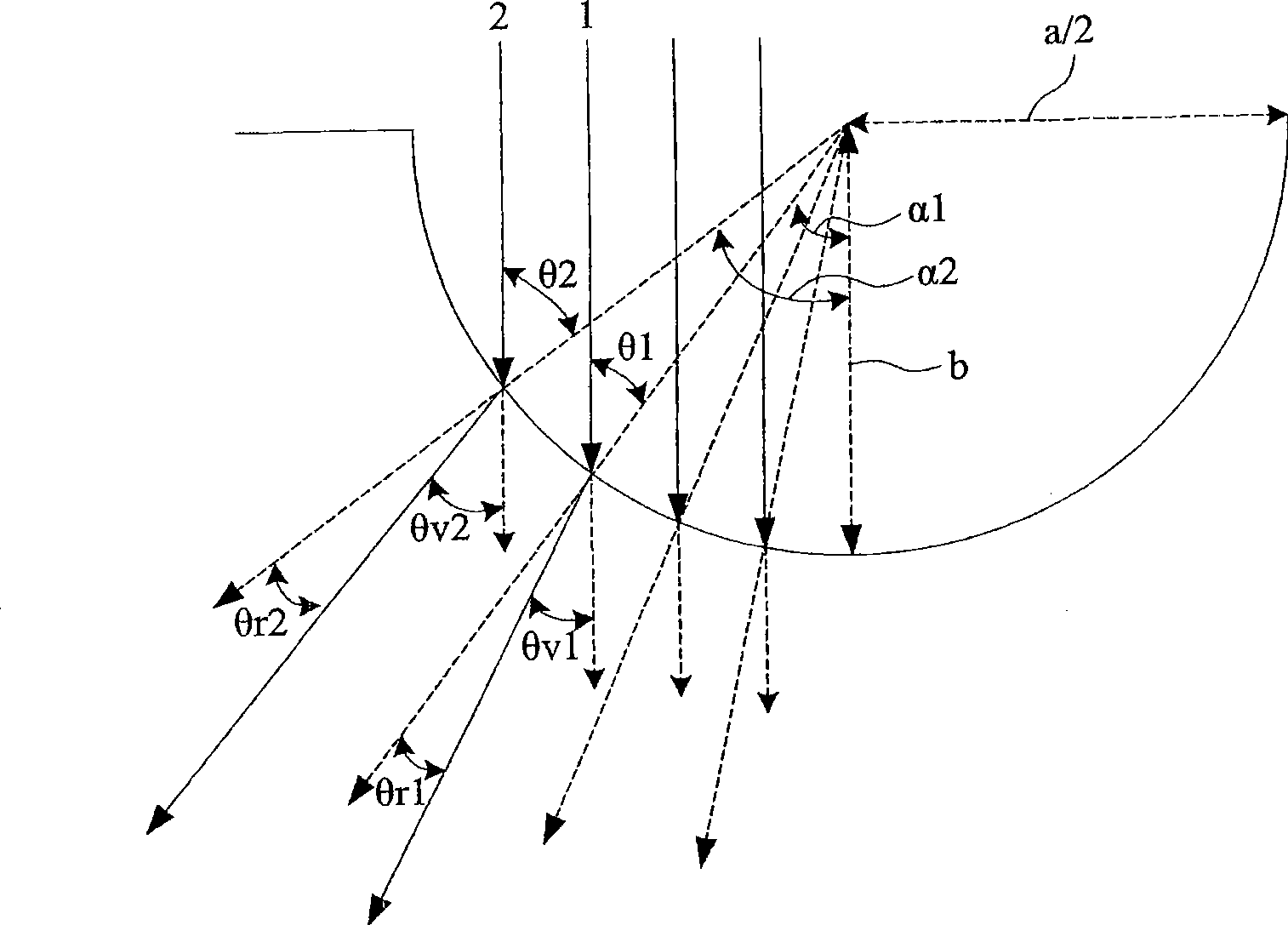

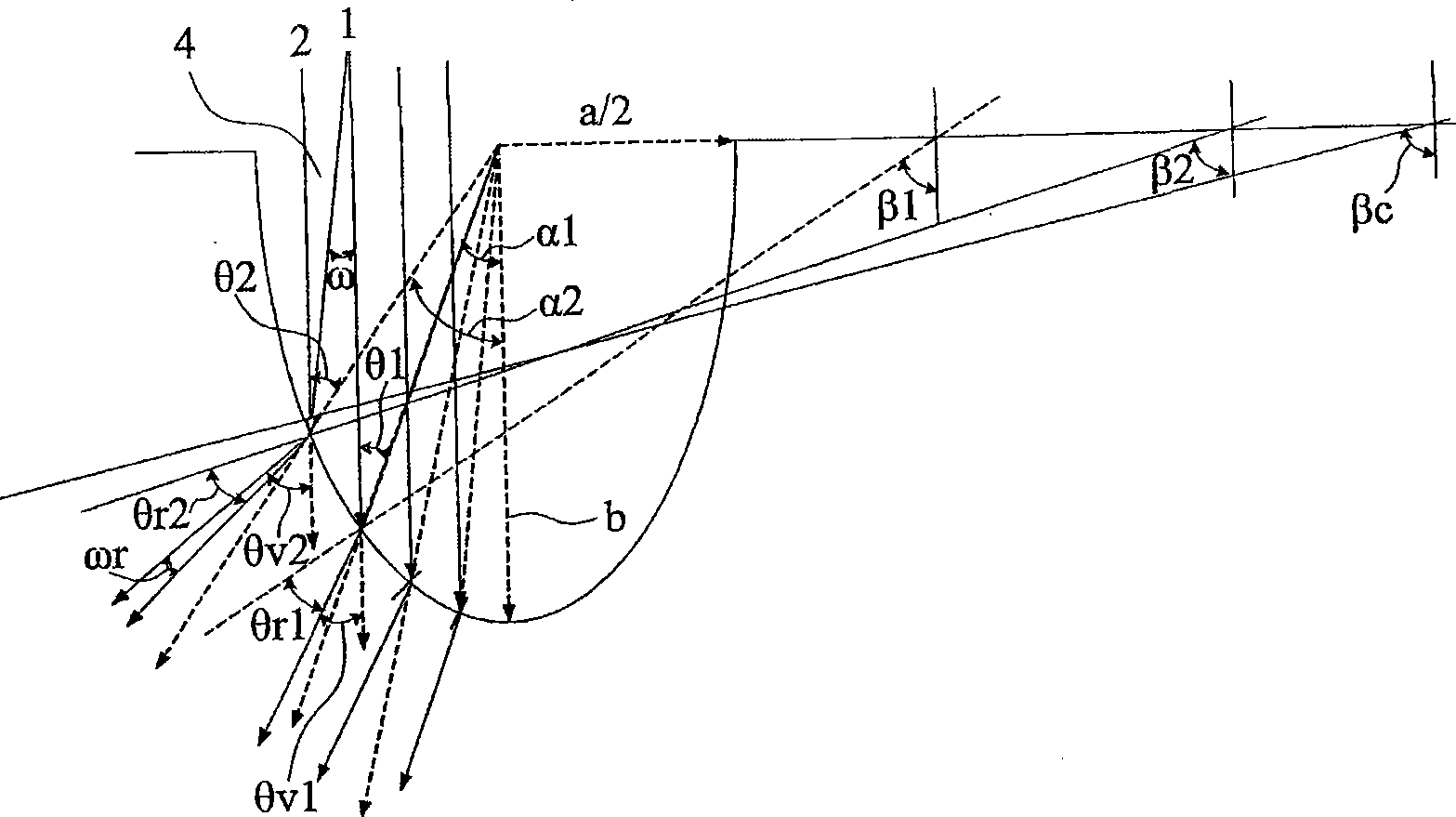

[0042] The composite light-guiding film module of the present invention mainly arranges a refraction member above a light-guiding film. After the light passes through the refracting member, a larger incident angle is generated, so that the light enters the light-guiding film and then passes through the light-guiding film. The total reflection is done in the diaphragm, and the larger the incident angle of the light will increase the amount of light transmitted by the total reflection of the light in the light guide diaphragm, reducing the loss of light due to penetration and scattering. The following is the relevant analysis.

[0043] figure 1 , 2 is a schematic diagram of light passing through a micro-concave lens structure.

[0044] figure 1 For the case of light passing through a hemispherical dimple lens.

[0045] 1, 2: Beam

[0046] a / 2: dimple lens aperture

[0047] b: Micro-concave lens depth

[0048] n1: air refractive index

[0049] n2: Refractive index of micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com