Support of olefinic polymerization catalyst and preparation method thereof, solid catalyst components for olefinic polymerization and olefinic polymerization catalyst

A solid catalyst and olefin polymerization technology, applied in the field of olefin polymerization catalysts, can solve the problems of complex operation, high content of fine powder, and inadequacy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

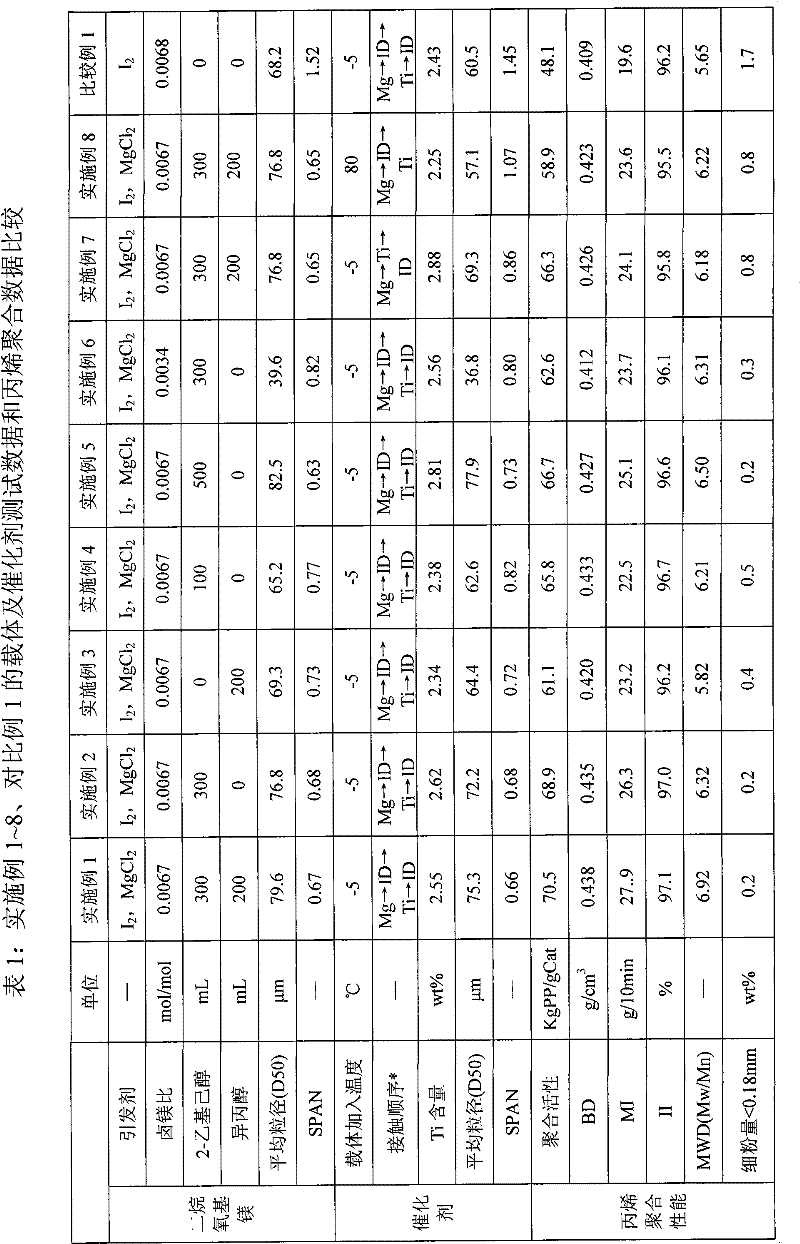

Examples

Embodiment 1

[0065] (1) Preparation of dialkoxymagnesium carrier

[0066] After the 16L pressure-resistant reactor with a stirrer was fully replaced with nitrogen, 10000 mL of ethanol, 300 mL of 2-ethylhexanol and 200 mL of isopropanol were added to the reactor, and 12 g of iodine and 8 g of magnesium chloride were added to dissolve them. After stirring, the temperature was raised until reaching the reflux temperature of the reaction system. Then add magnesium powder 640g successively. The reaction was carried out to completion, ie no more hydrogen evolution. It is then washed, separated and dried. The obtained dialkoxymagnesium carrier 1#.

[0067] (2) Preparation of catalyst components

[0068]Take the above-mentioned dialkoxymagnesium carrier 1#650g, 3250mL of toluene, and 65mL of di-n-butyl phthalate (DNBP) to prepare a suspension; add 2600mL of toluene to a 16L pressure-resistant reactor that has been repeatedly replaced by high-purity nitrogen and titanium tetrachloride 3900mL, ...

Embodiment 2

[0073] Except that in the preparation of the dialkoxymagnesium carrier, 10200 mL of ethanol was added and isopropanol was not added, the others were the same as in Example 1.

Embodiment 3

[0075] Except that in the preparation of the dialkoxymagnesium carrier, 10300 mL of ethanol was added and 2-ethylhexanol was not added, the others were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com