Method for preparing zirconia-alumina composite oxide xerogel

A composite oxide, aluminum hydroxide sol technology, used in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problem of rapid precipitation of zirconia, wide particle size distribution, and different particle sizes. problem, to achieve the effect of large pore volume, low preparation cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

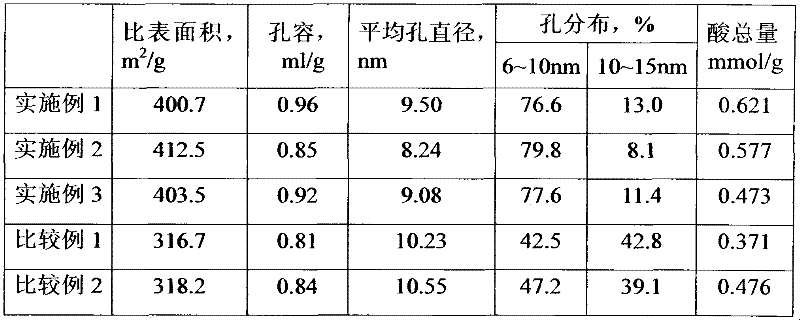

[0028] Mix 1000ml 2mol / L aluminum nitrate with 20ml silica gel (containing SiO 2 25 wt%), mixed with ammonia water to adjust the pH value to 7, and reacted at 80°C to obtain Sol A. 1mol / l ZrCl 4 The solution and dilute ammonia water were added dropwise in a beaker filled with ethanol and deionized water, the ethanol accounted for 15v% of the water, the pH value was controlled to 6.5, and the reaction temperature was 45°C to obtain Sol B. Mix sol B and sol A, stir for 2 hours, heat up to 50°C, age for 2 hours, add 200ml of ethanol, filter with suction, wash with deionized water for 3 times, dry at 120°C for 3 hours, and pulverize to obtain the composite oxide dry glue. Calcined at 600°C for 3 hours to obtain a composite oxide, in which the content of zirconia is 60wt%, and the content of silicon oxide is 1.5wt%. The main properties are listed in Table 1.

[0029] Take 123g of composite oxide dry glue, 13.9g of SB powder, add 3g of scallop powder, 5ml of dilute nitric acid, k...

Embodiment 2

[0031] Mix 100ml 2mol / L aluminum nitrate with 20ml silica gel (containing SiO 225 wt%), mixed with ammonia water to adjust the pH value to 7.0, and reacted at 60°C to obtain Sol A. Under the condition of stirring, oxalic acid (0.1mol / l) was slowly dropped into 0.1mol / l zirconium nitrate to make the pH value = 5.5, and after continuing to stir for 10 minutes, put it into a three-necked flask and heat it to 95°C, and reflux at a constant temperature for 2 Sol B was obtained in 1 hour. Dilute sol B twice with distilled water and mix it with sol A, stir for 2 hours, heat up to 50°C, age for 2 hours, add 200ml of ethanol, filter with suction, wash 3 times with deionized water, dry at 120°C for 3 hours and pulverize to obtain The composite oxide dry glue was calcined at 600°C for 3 hours to obtain a composite oxide, in which the content of zirconia was 30wt%, and the content of silicon oxide was 2wt%. The main properties are listed in Table 1.

[0032] Take 114g of composite oxide...

Embodiment 3

[0034] Mix 1 mol / L aluminum sulfate and 1 mol / L sodium aluminate in parallel, adjust the pH value to 7.0, and react at 50°C to obtain Sol A. All the other are identical with embodiment 1. Wherein the content of zirconia in the composite oxide is 10wt%, and its main properties are listed in Table 1.

[0035] Take 132g of composite oxide dry glue, 13.9g of SB powder, add 3g of scallop powder, 5ml of dilute nitric acid, knead, extrude, dry at 120°C for 3 hours, and roast at 600°C for 3 hours to obtain a composite oxide carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com