Power module and method for manufacturing same

A technology of a power module and a manufacturing method, which is applied in the manufacturing of semiconductor/solid-state devices, electrical components, and electric solid-state devices, etc., can solve the problems of reduced joint reliability, reduced joint reliability, and increased operating temperature, and can prevent reliability. Deterioration, thermal stress suppression, and quality improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0024]

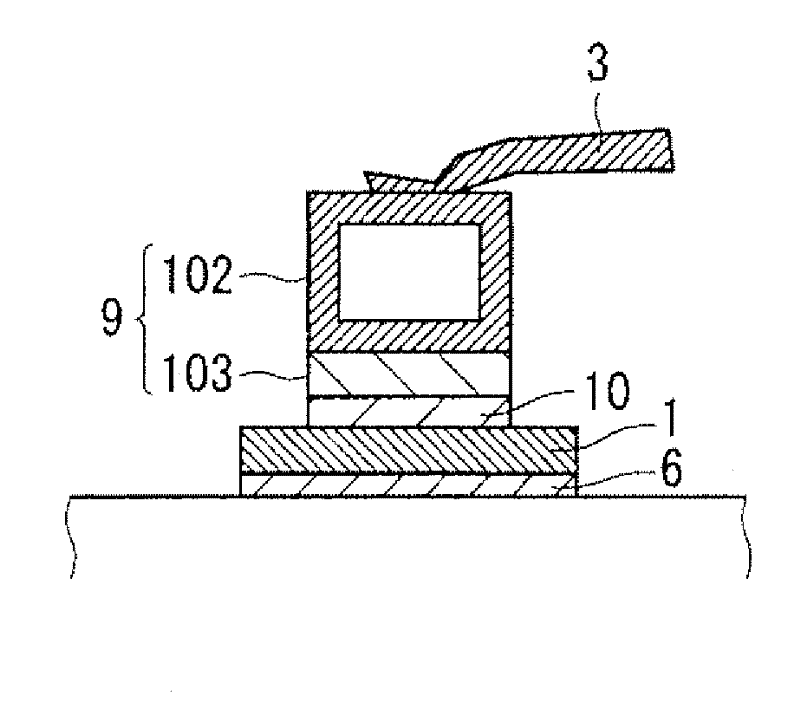

[0025] The power module according to Embodiment 1 of the present invention will be described using the drawings. Such as figure 1 As shown, the power module of the present invention is provided in the box body 8 with: a bottom plate 7; an insulating substrate 5 is arranged on the bottom plate 7 through the solder 6; a power element 1 is arranged on the insulating substrate 5 through the solder 6; The wiring member 9 as the first wiring member is bonded to the surface electrode of the power element 1 via the bonding material 10; the terminal 4 is connected to the wiring member 9 via the aluminum wire 3 as wiring; and the sealing material 2 is filled in the case 8 And covers insulating substrate 5 , power element 1 , wiring member 9 , and aluminum wire 3 . By using SiC or the like, which is a wideband gap semiconductor, as the power element 1 , a device capable of operating at a higher temperature can be realized.

[0026] The wiring member 9 is made of a highly con...

Embodiment approach 2

[0038]

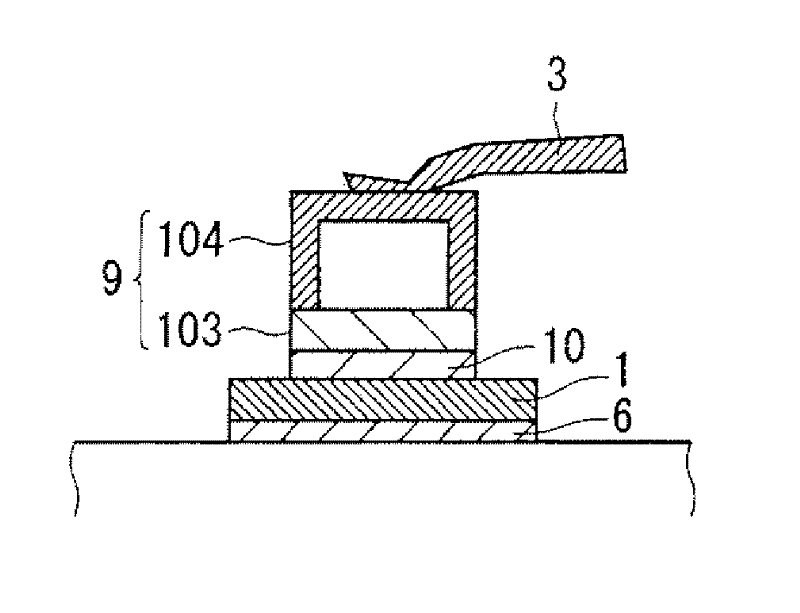

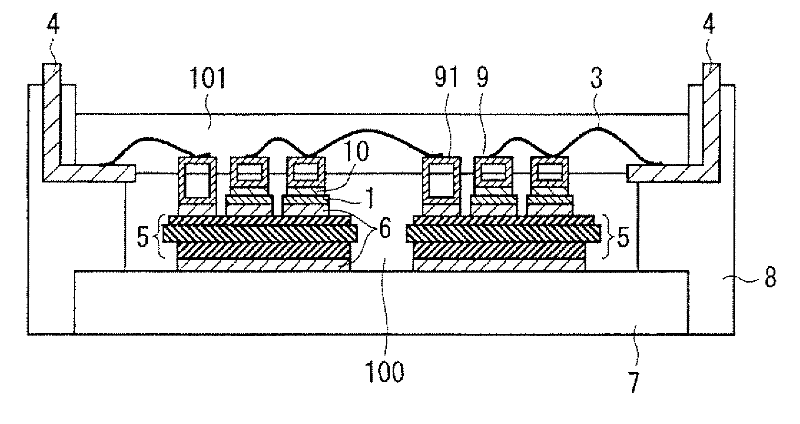

[0039] Figure 4 A power module according to Embodiment 2 is shown. As shown in the figure, in addition to the configuration of the power module shown in Embodiment 1, the power module further includes a wiring member 91 having a first side surface bonded to the insulating substrate 5 as a second wiring member. The rectangular cylindrical metal on the surface pattern connects the wiring member 91 and the terminal 4 via the aluminum wire 3 .

[0040] Here, the sealing material 2 can also be filled in the case body 8 as in the first embodiment, but in the second embodiment, the aluminum wire 3 is used on the side surface (the second side surface) where the wiring member 9 and the wiring member 91 are joined. ) is filled with a sealing material 100 (first sealing material) such as epoxy resin and cured so that at least it is exposed, and then the aluminum wire 3 is bonded to the exposed surfaces of the wiring members 9 and 91 . After that, the remaining exposed porti...

Embodiment approach 3

[0049]

[0050] Figure 5 A power module in the case of using a plurality of power elements connected in parallel in Embodiment 3 is shown. As shown in the figure, in addition to the configuration of the power module shown in Embodiment 2, the power module of Embodiment 3 further includes a wiring member 90, and the wiring members provided corresponding to each power element 1 are arranged on the second side surface side. joined to each other.

[0051] The wiring member 90 is an integral structure straddling a plurality of power elements 1 . With this structure, the intensity of ultrasonic vibrations to withstand the weight applied at the time of joining the aluminum wire 3 is further increased compared to Embodiment 2, and the surface area for heat dissipation is also increased due to the formation of the connection portion. Therefore, a further heat dissipation effect can be expected.

[0052]

[0053] According to Embodiment 3 of the present invention, in the power m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com