Method suitable for directly testing and evaluating quenching effect of aluminum alloy material

An aluminum alloy material and aluminum alloy technology, which is applied in the preparation of test samples, analysis materials, and test material hardness, etc., can solve the problems of large waste, difficult operation, and difficulty in measuring residual stress at the same time, and achieve strong operability , to ensure the consistency of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

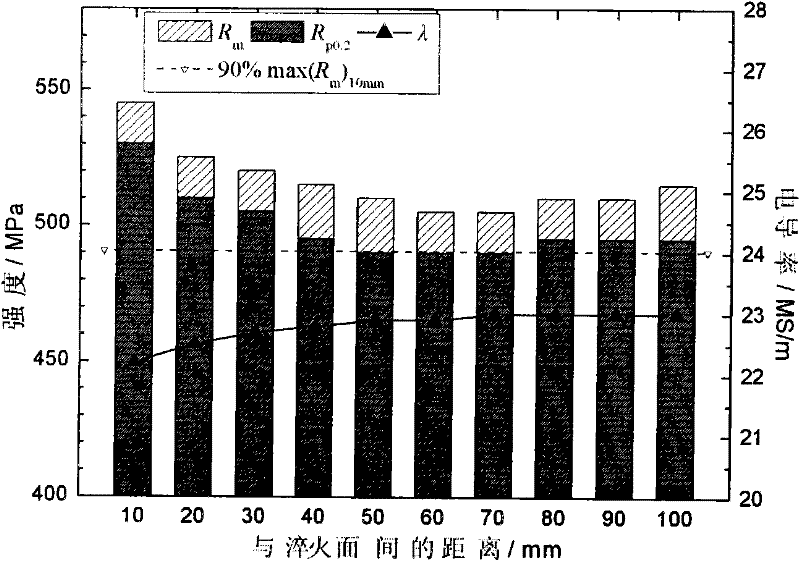

[0038] This embodiment is to test and evaluate the quenching effect of 210 mm thick Al-7.6Zn-1.8Mg-1.4Cu-0.12Zr (wt%) alloy forgings immersed in water at room temperature. Cut a quenched sample with a size of 210mm high x 150mm wide x 150mm long from a whole forging with a specification of 210mm thick x 600mm wide x 2000mm long, such as figure 1 as shown, figure 1 The dotted line in the figure shows the outline of the cube quenched sample, except that the upper and lower planes in the thickness direction are used as the quenching surface, and the other sides are heat-insulated. After solid solution treatment, it is quenched by water immersion at room temperature; and a thermocouple is embedded in the sample for real-time temperature monitoring. figure 1 A schematic diagram of the immersion and quenching sample and the position of the embedded thermocouple for temperature measurement is given. In order to obtain the cooling rate at different positions in the direction of samp...

Embodiment 2

[0042] Al-7.5Zn-1.7Mg-1.4Cu-0.12Zr (wt%) alloy thick plate, the specification of the whole thick plate is 120mm thick × 1000mm wide × 2500mm long, and the dimensions cut from it are 120mm high × 150mm long × 150mm For the wide quenched sample, except for the upper and lower planes in the thickness direction as the quenching surface, the other sides are heat-insulated. After solid solution treatment, spray quenching with water at room temperature, followed by T76 aging treatment; and a thermocouple is embedded in the sample for real-time temperature monitoring. Using this method, the maximum difference in strength in the thickness direction of the sample is 3.9%, and the maximum difference in conductivity is 2.1%. At the same time, the equivalent surface residual stress of the sample is measured to be 203MPa; the whole thick plate is tested in actual production. Spray quenching treatment, after aging treatment, the maximum difference in strength along the thickness direction of...

Embodiment 3

[0044] Al-7.5Zn-1.7Mg-1.4Cu-0.12Zr (wt%) alloy thick plate, the specification of the whole thick plate is 120mm thick × 800mm wide × 2000mm long, and the dimensions cut from it are 120mm high × 150mm long × 150mm For the wide quenched sample, except for the upper and lower planes in the thickness direction as the quenching surface, the other sides are heat-insulated. After solution treatment, immerse in 25% PAG quenching solution at room temperature, and then perform T76 aging treatment; and pre-embed thermocouples in the sample for real-time temperature monitoring. Using this method, the maximum difference in strength in the thickness direction of the sample is 9.2%, and the maximum difference in conductivity is 4.7%. At the same time, the equivalent surface residual stress of the sample is 61MPa; the whole thick plate is tested in actual production. Quenching treatment, after aging treatment, the maximum difference in the strength of the central part of the plate along the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com