Hydraulic station for feeding trolley

A technology of feeding trolley and hydraulic station, which is applied in the direction of fluid pressure actuators, conveyors, servo motors, etc., and can solve the problems of inaccurate control of feeding device feeding, feeding device stuck on the track, low production efficiency, etc. , to achieve the effect of simple structure, good self-priming performance and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

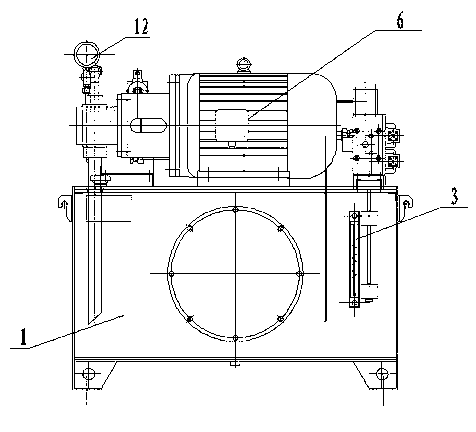

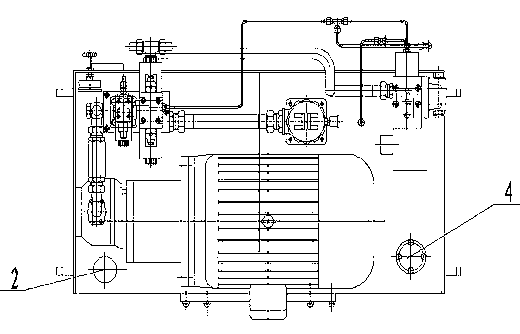

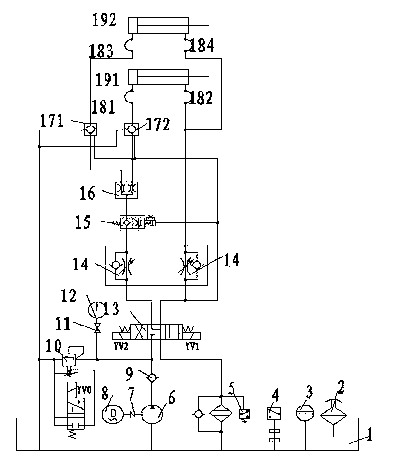

[0014] like figure 1 , figure 2 and image 3 As shown, the feeding trolley hydraulic station is mainly composed of a motor pump group, an executive cylinder, a control valve group and auxiliary devices. Collector valve 16, hydraulic control check valve 171, 172, electromagnetic overflow valve 10 and pipe check valve 9, auxiliary devices include fuel tank 1, air filter 2, liquid level gauge 3, liquid level controller 4, Oil return filter 5, elastic coupling 7, motor 8, shockproof pressure gauge 12 and 4 high-pressure hose joints 181, 182, 183, 184, motor pump unit, control valve group, liquid level controller 4, air filter The cleaner 2 and the oil return filter 5 are arranged on the top of the oil tank 1, the liquid level gauge 3 is arranged on the side of the oil tank 1, the motor 8 is connected with the motor pump unit through the elastic coupling 7, and two executive oil cylinders 191, 192 They are respectively connected to the control valve group through 4 high-pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com