Separator

A separator and eddy current separation technology, applied in the field of separators, can solve the problems of waste of resources, mediocre beneficiation effect, unusable resources, etc., to achieve the effect of eliminating nitrogen oxide emissions, solving water resource pollution, and solving water resource shortages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

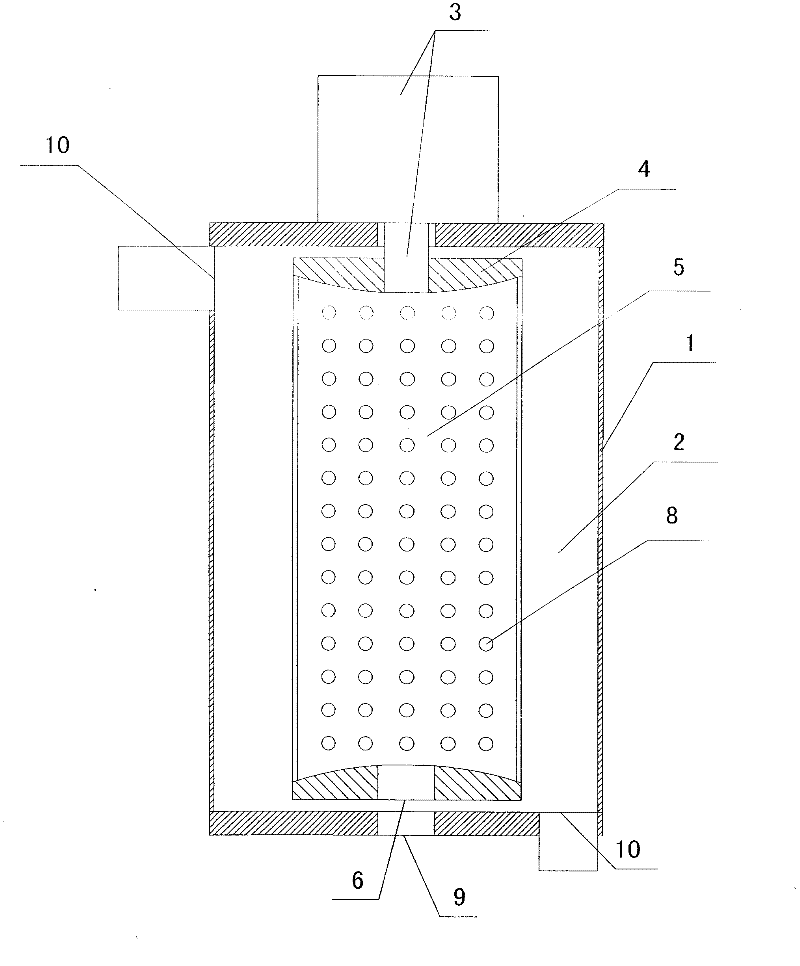

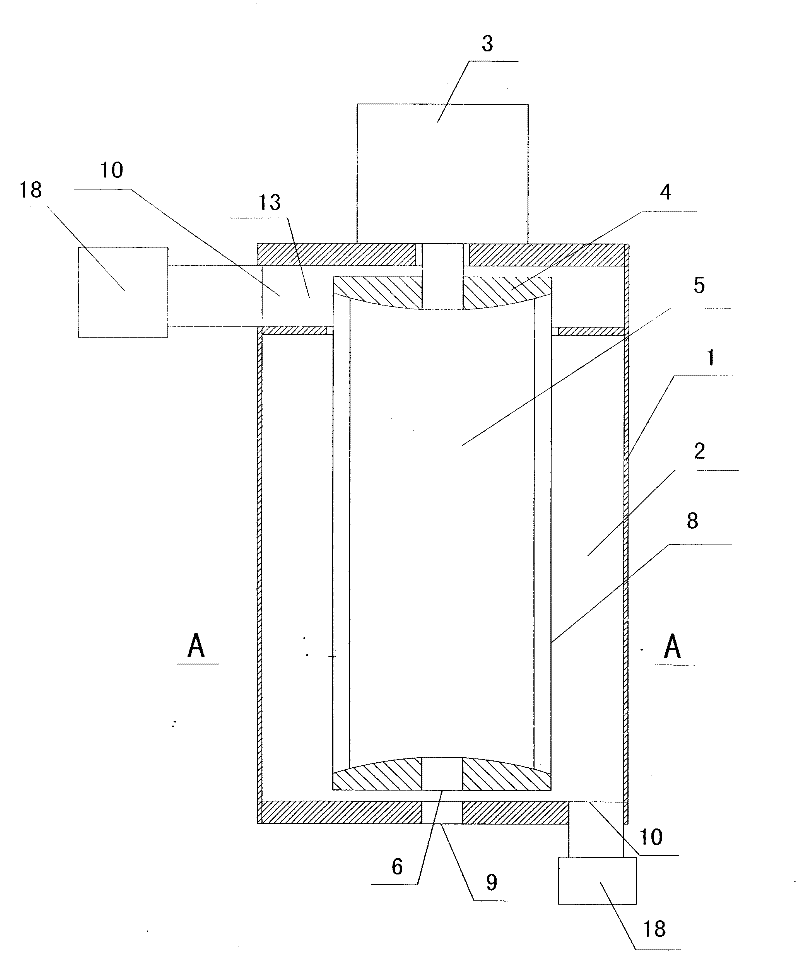

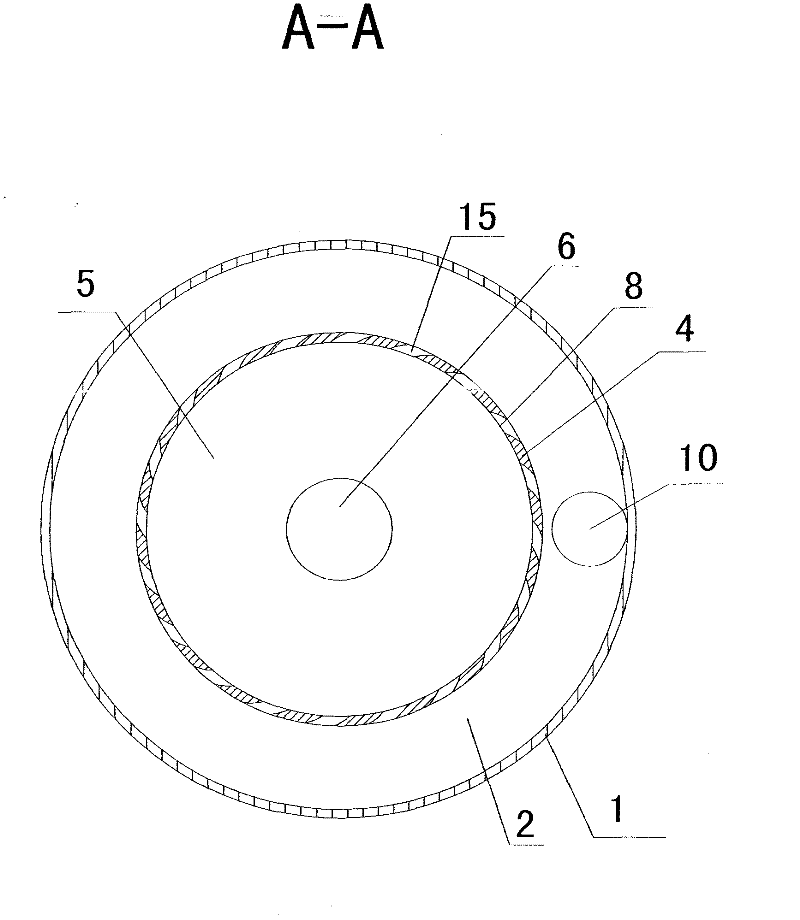

[0036] The main structure of the separator of the present invention includes a housing 1, at least one housing chamber 2 is arranged in the housing 1, a transmission device 3 is installed on the housing 1, a vortex separation cylinder 4 is arranged in the housing chamber 2, the transmission device 3 and the eddy current separation cylinder 4 Connection, the vortex separation cylinder 4 is provided with a vortex separation chamber 5, one end of the vortex separation chamber 5 is provided with a fluid inlet 6, and a plurality of vortex separation chamber outlets 8 are arranged on the outer periphery of the vortex separation chamber 5, and the shell cavity inlet 9 is set corresponding to the fluid inlet 6, and the shell cavity 2 At least two housing chamber outlets 10 are provided.

[0037] The scope of the casing 1 includes a base, a casing, and a power unit, and each part can be collectively referred to as a casing. The housing can also be integrated with the power device to fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com