High-pressure in-situ infrared spectroscopy apparatus for monitoring supercritical system on line

An infrared spectrum and infrared spectrometer technology, which is applied in the field of high-pressure in-situ infrared spectrum monitoring devices, can solve the problems of reduced reliability and reliability of measurement results, limited application scope, inability to realize stirring, etc., and achieves improved mass transfer diffusion rate and Test efficiency, overcome the complex structure, and the effect of reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

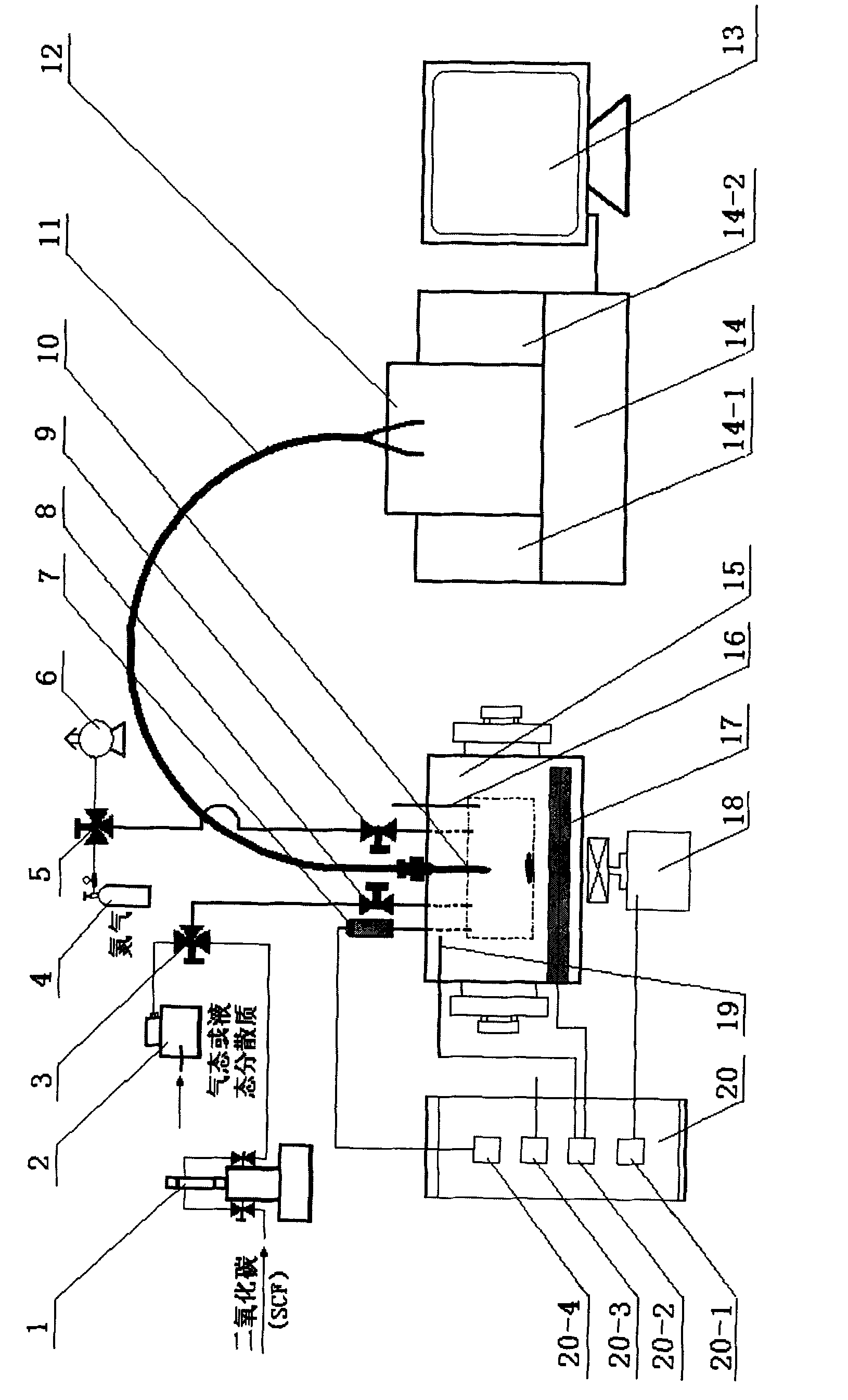

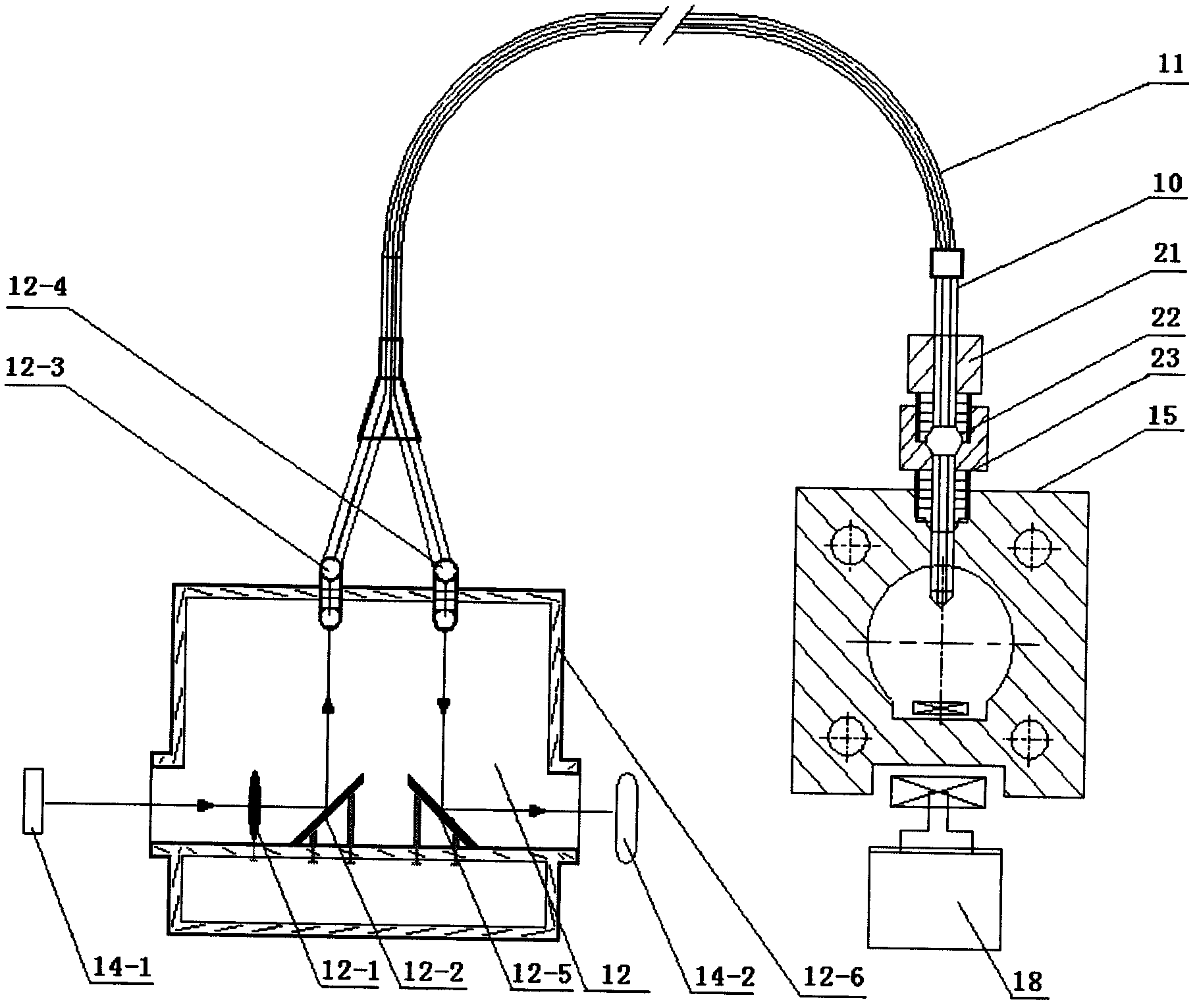

[0021] exist figure 1 Among them, the high-pressure in-situ infrared spectroscopy device for on-line monitoring of supercritical systems in this embodiment consists of a high-pressure injection pump 1, a metering pump 2, a gas-liquid three-way valve 3, a nitrogen cylinder 4, a nitrogen three-way valve 5, a vacuum pump 6, and a pressure sensor 7. Injection valve 8, exhaust valve 9, infrared sensor 10, optical fiber 11, reflection chamber 12, computer 13, infrared spectrometer 14, high pressure reactor 15, temperature measuring thermocouple 16, heater 17, electromagnetic stirrer 18 , temperature control thermocouple 19, controller 20, sealing pressure cap 21, sealing ferrule 22, and sealing joint 23 are connected to form.

[0022]An electromagnetic stirrer 18 is installed under the lower surface of the high-pressure reactor 15, and the electromagnetic stirrer 18 is connected to the governor 20-1 on the controller 20 through a wire, and the governor 20-1 controls the operating st...

Embodiment 2

[0027] The attenuation total reflection prism 10-2 of the infrared sensor 10 of the present embodiment is a single crystal silicon crystal attenuation total reflection prism, the front end part of the optical fiber 11 penetrates into the inner cavity of the sensor housing 10-1, and the end of the optical fiber 11 is bonded to the The upper end face of the attenuated total reflection prism 10-2. The shape of the present embodiment attenuating total reflection prism 10-2 is a conical prism at the top, and the bottom is a triangular prism whose side is connected with the bottom surface of the conical truncated body. The angle α between the other two side attenuated total reflection detection planes R1 and attenuated total reflection detection plane R2 is 90°. The other components and the connection relationship of the components are the same as in Embodiment 1. The performance parameters of the high-pressure in-situ infrared spectroscopy device for on-line monitoring of the supe...

Embodiment 3

[0029] The attenuation total reflection prism 10-2 of the infrared sensor 10 of the present embodiment is a single crystal silicon crystal attenuation total reflection prism, the front end part of the optical fiber 11 penetrates into the inner cavity of the sensor housing 10-1, and the end of the optical fiber 11 is bonded to the The upper end face of the attenuated total reflection prism 10-2. The shape of the attenuating total reflection prism 10-2 of the present embodiment is a frustum of a cone, and the bottom is a triangular prism whose side is connected with the bottom of the frustum of a cone. The angle α between the other two side attenuated total reflection detection planes R1 and attenuated total reflection detection plane R2 is 90°. The other components and the connection relationship of the components are the same as in Embodiment 1. The performance parameters of the high-pressure in-situ infrared spectroscopy device for on-line monitoring of the supercritical sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com