Method for electrodepositing metal lanthanum in ionic liquid

An ionic liquid and metal lanthanum technology, which is applied in the field of electrodeposited metal lanthanum, can solve the problem of not being able to obtain a single metal lanthanum deposition layer, and achieve the effects of excellent conductivity, low viscosity, and wide electrochemical window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0016] Specific embodiment one: a kind of method for electrodepositing metal lanthanum in ionic liquid of the present embodiment is to carry out in the glove box of argon atmosphere according to the following steps:

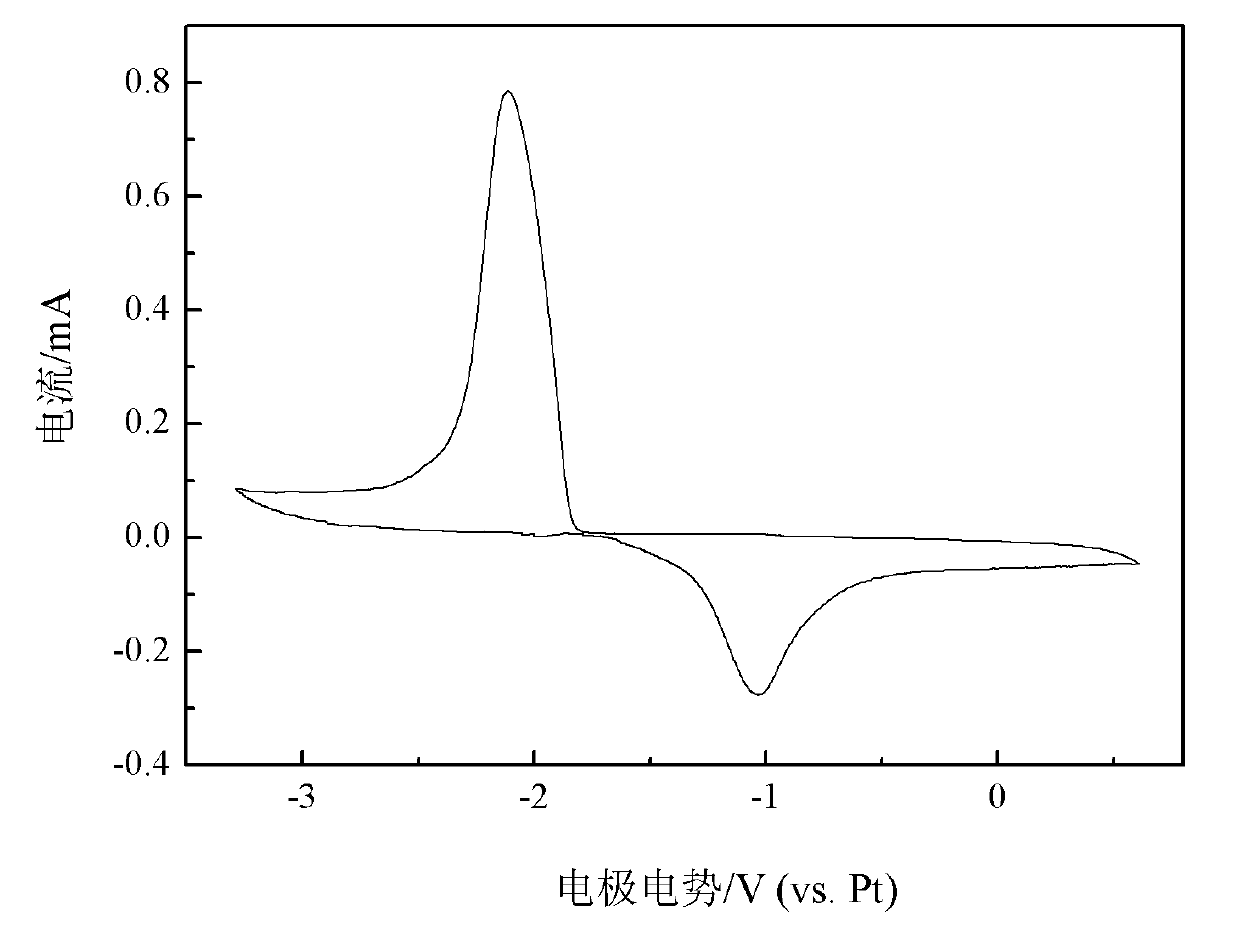

[0017] 1. Add anhydrous lanthanum chloride to the ionic liquid according to the molar ratio of anhydrous lanthanum chloride to ionic liquid at a ratio of 1:2 to 4, and mix evenly to obtain an electroplating solution; the ionic liquid is 1-formazol Base-3-ethylimidazole bis(trifluoromethylsulfonyl)imide;

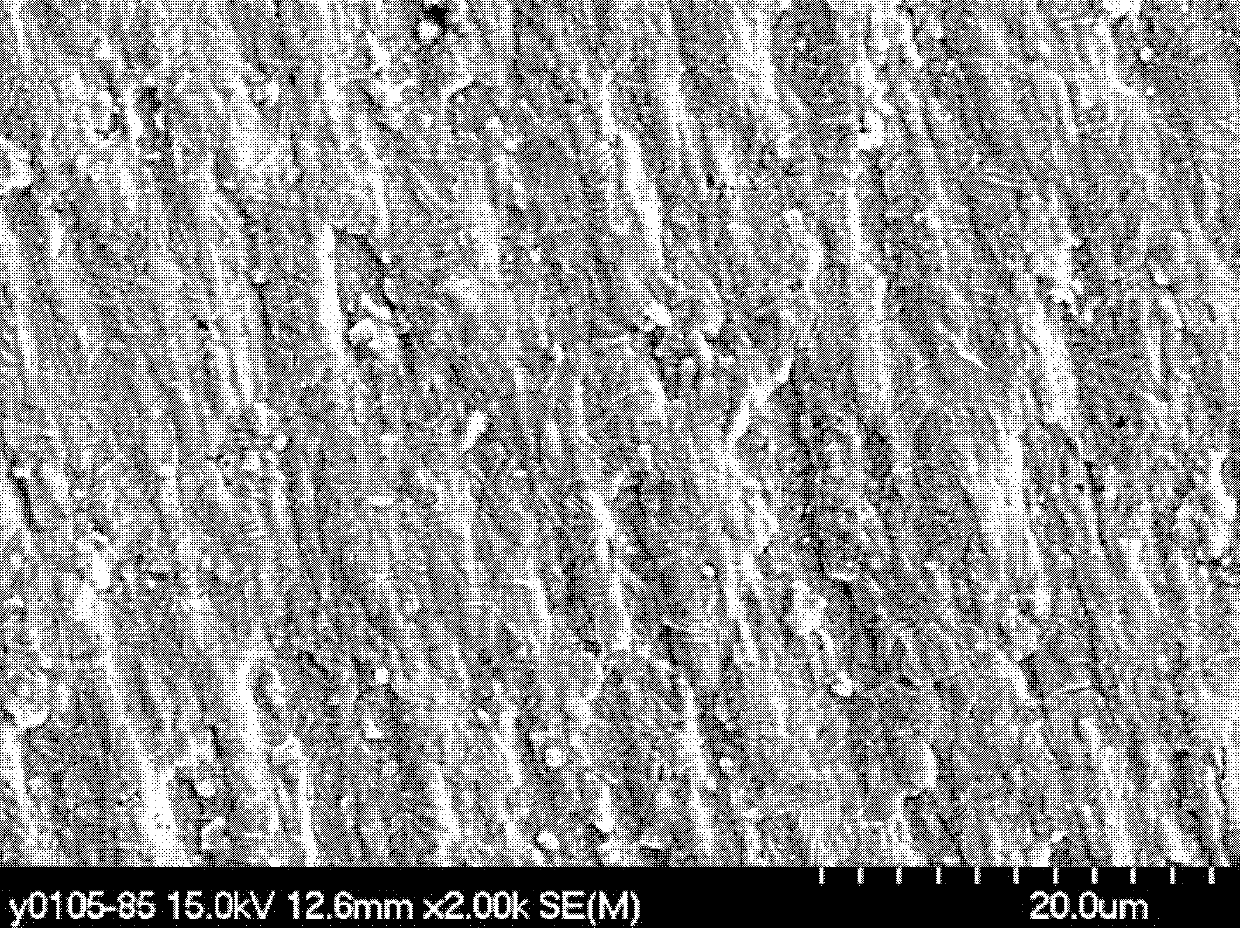

[0018] 2. Take the pretreated copper sheet as the cathode, and use platinum, graphite or titanium-based oxide as the anode. The distance between the cathode and the anode is 1cm to 5cm. The electroplating solution prepared in step 1 is used in a constant current mode. The current density is 10A / m 2 ~100A / m 2 , Electroplating for 1min to 30min at a temperature of 25°C to 50°C;

[0019] 3. After taking out the copper sheet, wash it with ethanol first, then wash...

specific Embodiment approach 2

[0021] Embodiment 2: This embodiment differs from Embodiment 1 in that the pretreatment process in step 2 is as follows: a. Alkaline degreasing: immerse the copper sheet in a conventional alkaline degreasing solution until the oil is completely removed; b, pickling: immerse the copper sheet processed in step a into hydrochloric acid with a mass concentration of 20% for 10 to 30 seconds; c, water washing: wash the copper sheet processed in step b with water, and then dry it. Complete the pretreatment of copper sheet. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the molar ratio of anhydrous lanthanum chloride to ionic liquid in step 1 is 1:2.3-3.5. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com