Blast furnace flux and application thereof

A flux and blast furnace technology, applied in the field of metallurgy, can solve the problems of heat consumption, dilute reducing atmosphere, increase coke ratio, etc., and achieve the effect of reducing coke consumption, reducing production cost and broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

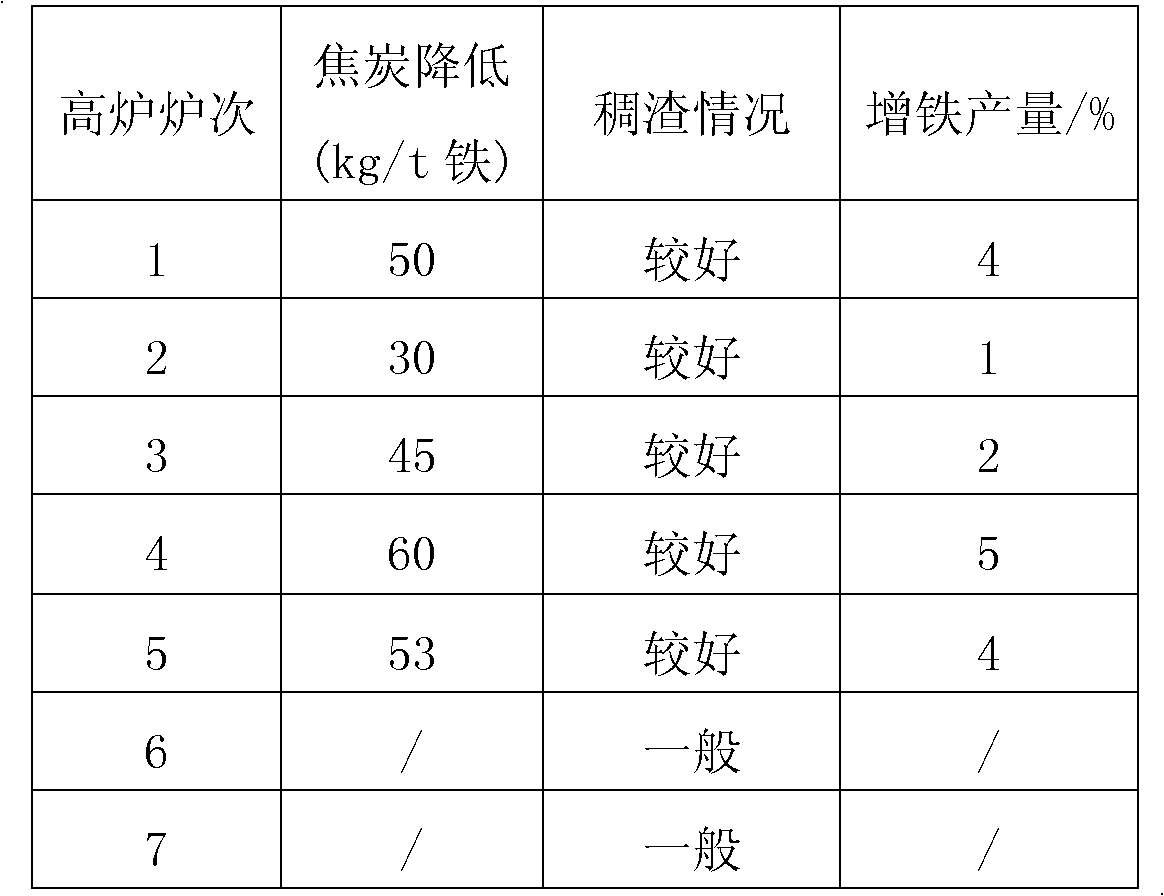

Examples

Embodiment Construction

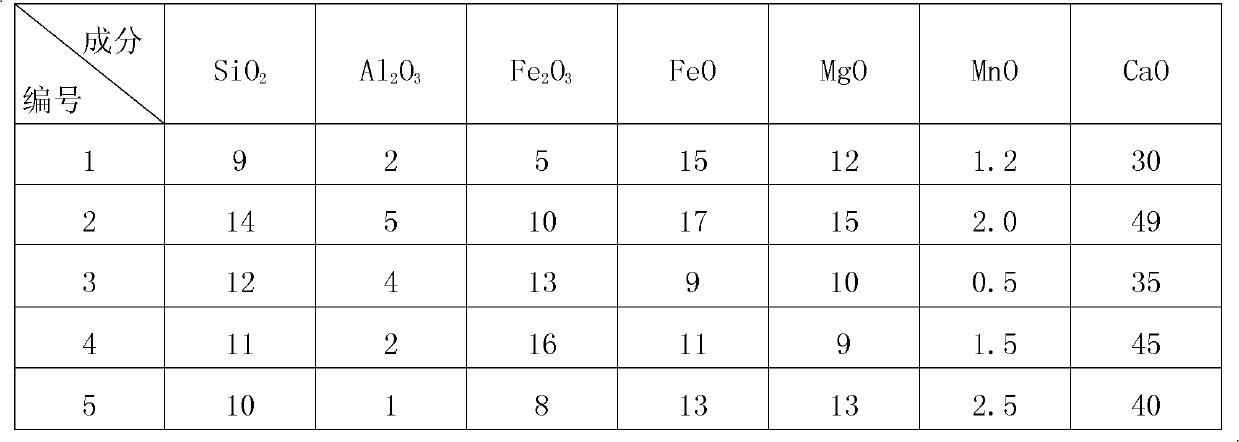

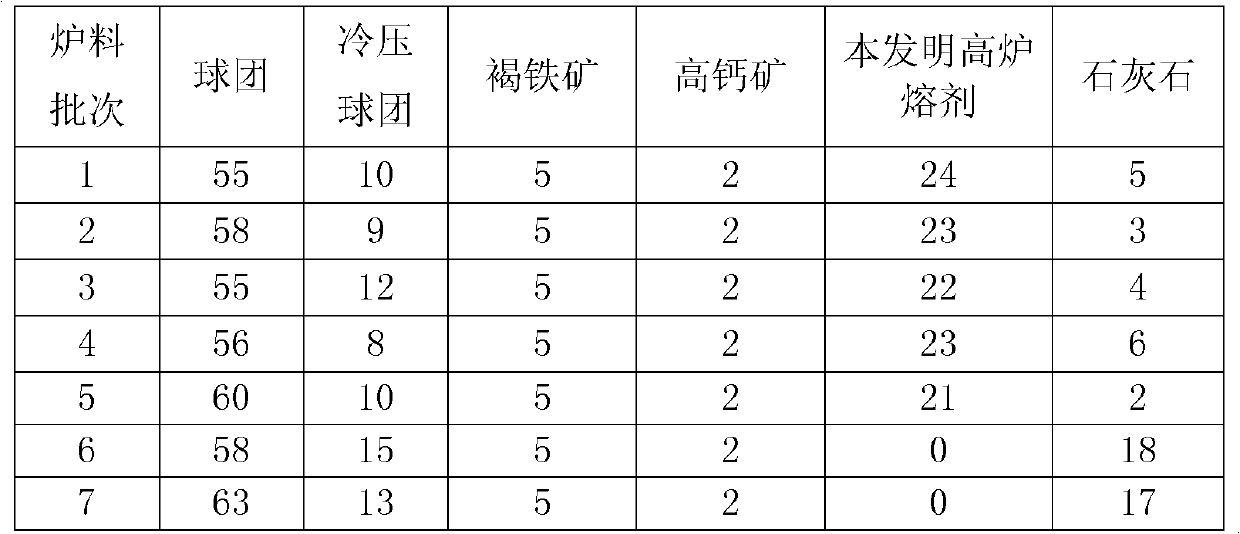

[0013] The blast furnace flux of the present invention contains the following components by weight ratio: SiO 2 4 to 16 parts, Al 2 o 3 1 to 10 parts, Fe 2 o 3 5 to 20 parts, 5 to 30 parts of FeO, 2 to 20 parts of MgO, 20 to 60 parts of CaO, 1 to 50 parts of MFe (MFe means free iron, metal iron).

[0014] Wherein, the blast furnace flux of the present invention may also contain ≤10 parts of MnO in proportion by weight and the content of MnO is >0.

[0015] Among them, the blast furnace flux of the present invention is preferably composed of components in the following weight ratio: SiO 2 4 to 16 parts, Al 2 o 3 1 to 10 parts, Fe 2 o 3 5-20 parts, 5-30 parts of FeO, 2-20 parts of MgO, 20-60 parts of CaO, 1-50 parts of MFe, 0-10 parts of MnO.

[0016] Further, in order to improve the use effect of the blast furnace flux of the present invention, the particle diameter of the blast furnace flux is preferably 10-150mm.

[0017] In the blast furnace flux of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com