Yellow phosphorus ore processing technology

A processing technology and ore technology, which is applied in the field of yellow phosphorus ore processing technology, can solve the problems of high energy consumption and low output of yellow phosphorus production, and achieve the effects of reducing power consumption, increasing production, and reducing coke consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

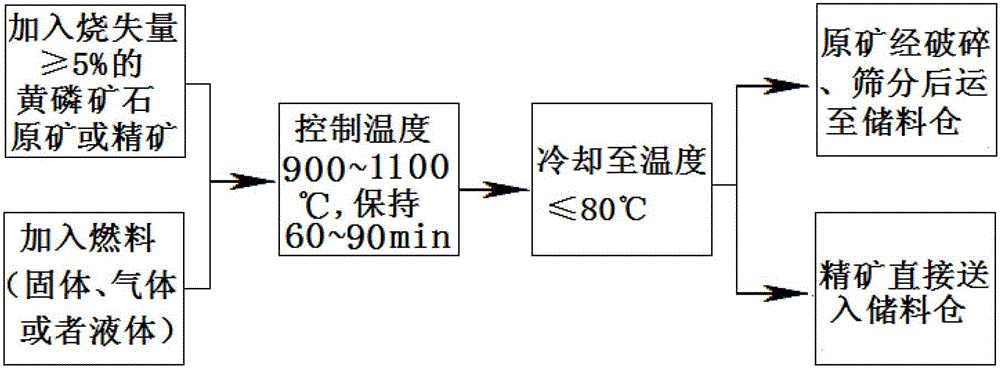

[0014] (1) Take raw ore of yellow phosphorus ore with loss on ignition ≥ 5% and diameter ≤ 300mm, or concentrate of yellow phosphorus ore with loss on ignition ≥ 5% and diameter of 15-80mm after processing, and calculate the unit by chemical analysis The quantity of yellow phosphorite heated to 1100°C requires heat and the heat content of the fuel used, and the ratio of required heat to available heat is 1:1.05 to obtain the weight ratio of yellow phosphorite to fuel, and according to this The proportion of yellow phosphorus ore and fuel is continuously added to the heating device;

[0015] (2) Control the temperature in the heating device within the range of 900°C to 1100°C for 60 to 90 minutes;

[0016] (3) After cooling the heated yellow phosphorus ore to a temperature of ≤80°C; the raw ore is crushed and screened and transported to the storage bin for standby, and the yellow phosphorus ore concentrate is directly transported to the storage bin for standby.

[0017] The fu...

Embodiment 1

[0020] Take the raw ore of yellow phosphorus ore with loss on ignition ≥ 5% and diameter ≤ 300mm, calculate the heat required to heat a unit amount of yellow phosphorus ore to 1100°C and the heat content of the fuel used, according to the required heat and The ratio of available heat is 1:1.05, and the weight ratio of yellow phosphate ore and fuel is obtained, and the yellow phosphate ore and solid fuel are continuously added to the smoke-reducing heating device according to this ratio; then the heating temperature is controlled to 1100°C, Keep it for 90 minutes; cool the heated yellow phosphorus ore to 80°C, crush and screen it and transport it to the storage bin for standby.

Embodiment 2

[0022] Take the raw ore of yellow phosphorus ore with loss on ignition ≥ 5% and diameter ≤ 200mm, calculate the heat required for heating a unit amount of yellow phosphorus ore to 1050°C and the heat content of the fuel used, according to the required heat and The available heat ratio is 1:1.05, and the weight ratio of yellow phosphate rock and fuel is obtained, and the yellow phosphorite and gas fuel are continuously added to the trolley heating device according to this ratio; then the heating temperature is controlled to be 1050°C, and the 90 minutes; after cooling the heated yellow phosphorus ore to 80°C, it is crushed and screened and transported to the storage bin for standby.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com