Method for preparing high-optical purity pitavastatin calcium

A technology of pitavastatin calcium and optical purity, applied in the field of preparation of cholesterol-lowering drugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

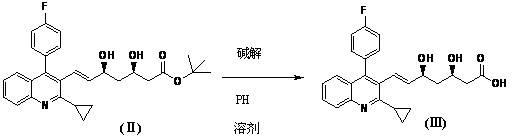

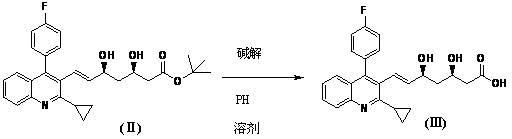

[0037] In a 1000ml four-neck flask, add 600ml methanol, 33g (0.0638mol) (3R,5S)-dihydroxy-7-[2-cyclopropyl-4-(4-fluorophenyl)-3-quinoline base]-3,5-dihydroxy-3,5-Oisopropylidene-6-heptenoic acid tert-butyl ester (I), at 10°C, add 85ml of 1mol / L hydrochloric acid, and react for 1 hour to obtain (3R ,5S)-dihydroxy-7-[2-cyclopropyl-4-(4-fluorophenyl)-3-quinolinyl]-6-(E)-heptenoic acid tert-butyl ester (Ⅱ) methanol solution .

[0038] Add 85ml of 1mol / L sodium hydroxide solution to the methanol solution of (II) above, stir for 2 minutes, then add 64ml of 1mol / L sodium hydroxide solution, and react for 2 hours. Recover under reduced pressure at 55°C, stop recovery when about 100-200ml remains, add water to 250ml, extract twice with 300ml dichloromethane each, adjust the acidity of the water layer to pH 4-5, extract with 300ml dichloromethane , washed with 50ml of purified water to obtain (3R,5S)-dihydroxy-7-[2-cyclopropyl-4-(4-fluorophenyl)-3-quinolyl]-6-(E)-heptenoic acid (Ⅲ) i...

Embodiment 2

[0042] In a 1000 ml four-necked flask, add 600 ml of tetrahydrofuran, 33 g (0.0638 mol) (3R,5S)-dihydroxy-7-[2-cyclopropyl-4-(4-fluorophenyl)-3-quinoline base]-3,5-dihydroxy-3,5-Oisopropylidene-6-heptenoic acid tert-butyl ester (I), at 50°C, add 100ml of 1mol / L sulfuric acid, and react for 1 hour to obtain (3R ,5S)-dihydroxy-7-[2-cyclopropyl-4-(4-fluorophenyl)-3-quinolyl]-6-(E)-heptenoic acid tert-butyl ester (Ⅱ) tetrahydrofuran solution .

[0043]Add 85 ml of 1 mol / L sodium hydroxide solution to the tetrahydrofuran solution of (II) above, stir for 2 minutes, then add 64 ml of 1 mol / L sodium hydroxide solution, and react for 2 hours. Recover under reduced pressure at 55°C, stop the recovery when there are about 100-200ml remaining, add water to 250ml, extract twice with 300ml methyl tert-butyl ether, adjust the acidity of the water layer to about 5, and use 300mM methyl Extracted with tert-butyl ether, washed with 50ml of purified water to obtain (3R,5S)-dihydroxy-7-[2-cyclo...

Embodiment 3

[0047] In a 1000ml four-neck flask, add 600ml of ethanol, 33g (0.0638mol) (3R,5S)-dihydroxy-7-[2-cyclopropyl-4-(4-fluorophenyl)-3-quinoline base]-3,5-dihydroxy-3,5-Oisopropylidene-6-heptenoic acid tert-butyl ester (Ⅰ), at 25°C, add 85ml of 1mol / L hydrochloric acid, and react for 1 hour to obtain (3R ,5S)-dihydroxy-7-[2-cyclopropyl-4-(4-fluorophenyl)-3-quinolyl]-6-(E)-heptenoic acid tert-butyl ester (Ⅱ) ethanol solution .

[0048] Add 85ml of 1mol / L sodium hydroxide solution to the ethanol solution of (II) above, stir for 2 minutes, then add 64ml of 1mol / L sodium hydroxide solution, and react for 2 hours. Recover under reduced pressure at 55°C, stop recovery when about 100-200ml remains, add water to 250ml, extract twice with 300ml toluene each, adjust the acidity of the aqueous layer to pH 2-3, extract with 300ml dichloromethane, 50ml Purified and washed with water to obtain (3R,5S)-dihydroxy-7-[2-cyclopropyl-4-(4-fluorophenyl)-3-quinolyl]-6-(E)-heptenoic acid (Ⅲ ) in dichl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com