Biodegradable strontium-doped calcium sulfate material having biological activity, and its preparation method and use

A bioactive and biodegradable technology, which is applied in the field of preparation and bioactive strontium-doped calcium sulfate materials, can solve the problems of component uniformity, particle size control, and difficulty in achieving satisfactory degradability of calcium sulfate, so as to improve biological effects and consumption The effect of low energy and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Will contain 0.2 mol / L CaCl 2 and 0.04 mol / L Sr(NO 3 ) 2 250 mL aqueous solution containing 0.04 mol / L sodium dodecylsulfonate was mixed, and then the mixed solution was added dropwise to the 0.12 mol / L (NH 4 ) 2 SO 4 In 500 mL of aqueous solution, a chemical precipitation reaction occurs, and particles are precipitated. After centrifugation, they are washed twice with deionized water and absolute ethanol, and then washed at 80 o C dried under vacuum to obtain strontium-doped calcium sulfate dihydrate.

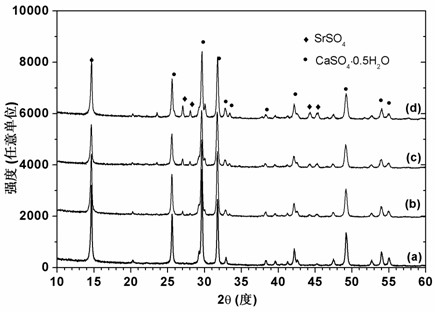

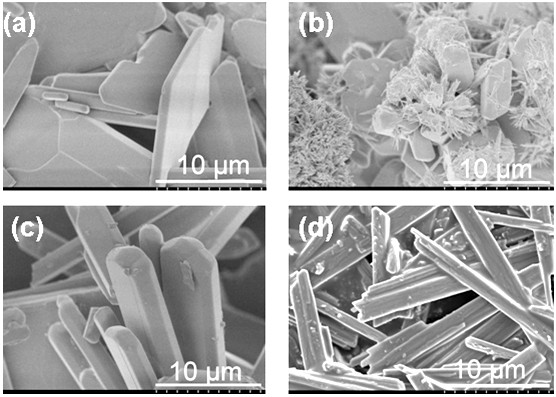

[0031] 2) The strontium-doped calcium sulfate dihydrate particles prepared in the above step 1) were mixed at 155 o C oven was heat-treated for 1 hour, and then 10 g of microparticles after heat treatment were mixed with 6 g of normal saline to form a paste, which gradually solidified after 4 hours of hydration reaction and formed a porous solidified material. Tested by flame plasma emission spectrometry, the strontium content in the particles after heat treatm...

Embodiment 2

[0033] The preparation method is the same as in Example 1, except that step 1) will contain 0.4 mol / L CaCl 2 and 0.08 mol / L Sr(AC) 2 250 mL aqueous solution containing 0.08 mol / L sodium dodecylsulfonate was mixed, and then the mixed solution was added dropwise to the 0.24 mol / L (NH 4 ) 2 SO 4 In 500 mL aqueous solution, a chemical precipitation reaction occurs, and the dried particles are at 160 o Under C, process 2 hours, all the other processes are with embodiment 1. Tested by flame plasma emission spectrometry, the strontium content in the particles after heat treatment is 1.23%, with figure 1 (b) The particle X-ray diffraction pattern after heat treatment is mainly the diffraction peak of α-calcium sulfate hemihydrate, and contains a weak SrSO 4 diffraction peaks, indicating that the particles contain a small amount of SrSO 4 ; attached figure 2 The scanning electron micrograph of (b) shows that the particles after heat treatment are flake-like and rod-like mixed ...

Embodiment 3

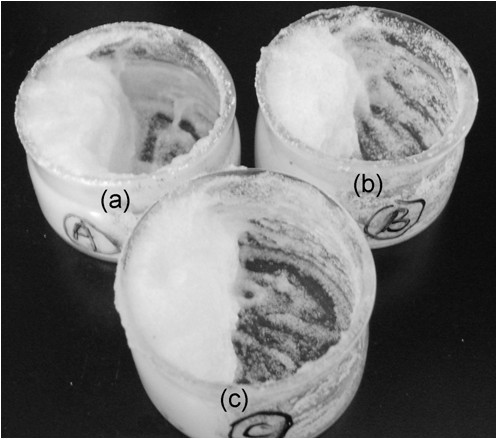

[0035] The preparation method is the same as in Example 1, except that step 1) will contain 0.8 mol / L Ca(AC) 2 and 0.24 mol / L Sr(NO 3 ) 2 250 mL aqueous solution containing 0.2 mol / L sodium dodecylsulfonate was mixed, and then the mixed solution was added dropwise to the 0.52 mol / L K containing 0.52 mol / L K 2 SO 4 In the 500 mL aqueous solution, chemical precipitation reaction occurs, and all the other treatments are the same as in Example 1. Tested by flame plasma emission spectrometry, the strontium content in the particles after heat treatment is 3.68%, with figure 1 (c) The particle X-ray diffraction pattern after heat treatment is mainly the diffraction peak of α-calcium sulfate hemihydrate, and contains a small amount of SrSO 4 diffraction peaks, indicating that the particles contain a small amount of SrSO 4 ; attached figure 2 The scanning electron micrograph of (c) shows that the particles after heat treatment are rod-shaped particles; image 3 (c) The heat-tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com