Manufacturing process of HDI (High Density Interconnection) board

A process and circuit board technology, applied in the field of HDI board production process, can solve problems such as hidden quality problems, increase production process and production cycle, circuit board deformation, etc., to achieve good dimensional stability, shorten production cycle, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to illustrate the idea and purpose of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0022] The present invention provides a production process of HDI boards, which is mainly used to solve the problems caused by many production processes due to the requirement that the outer laser blind holes are completely filled or the filling degree is greater than 85% in the current production process of HDI boards. The problem of long production cycle.

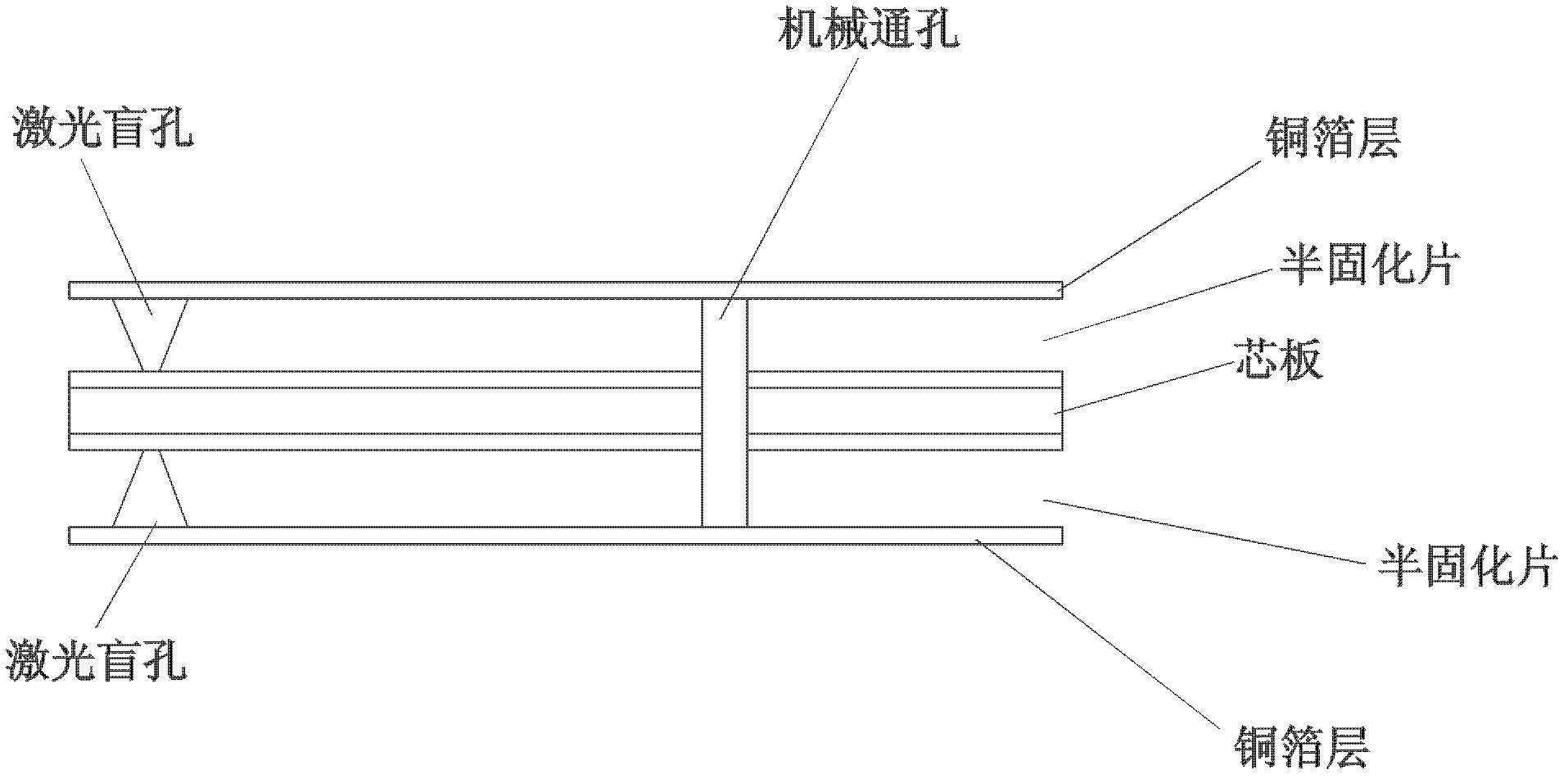

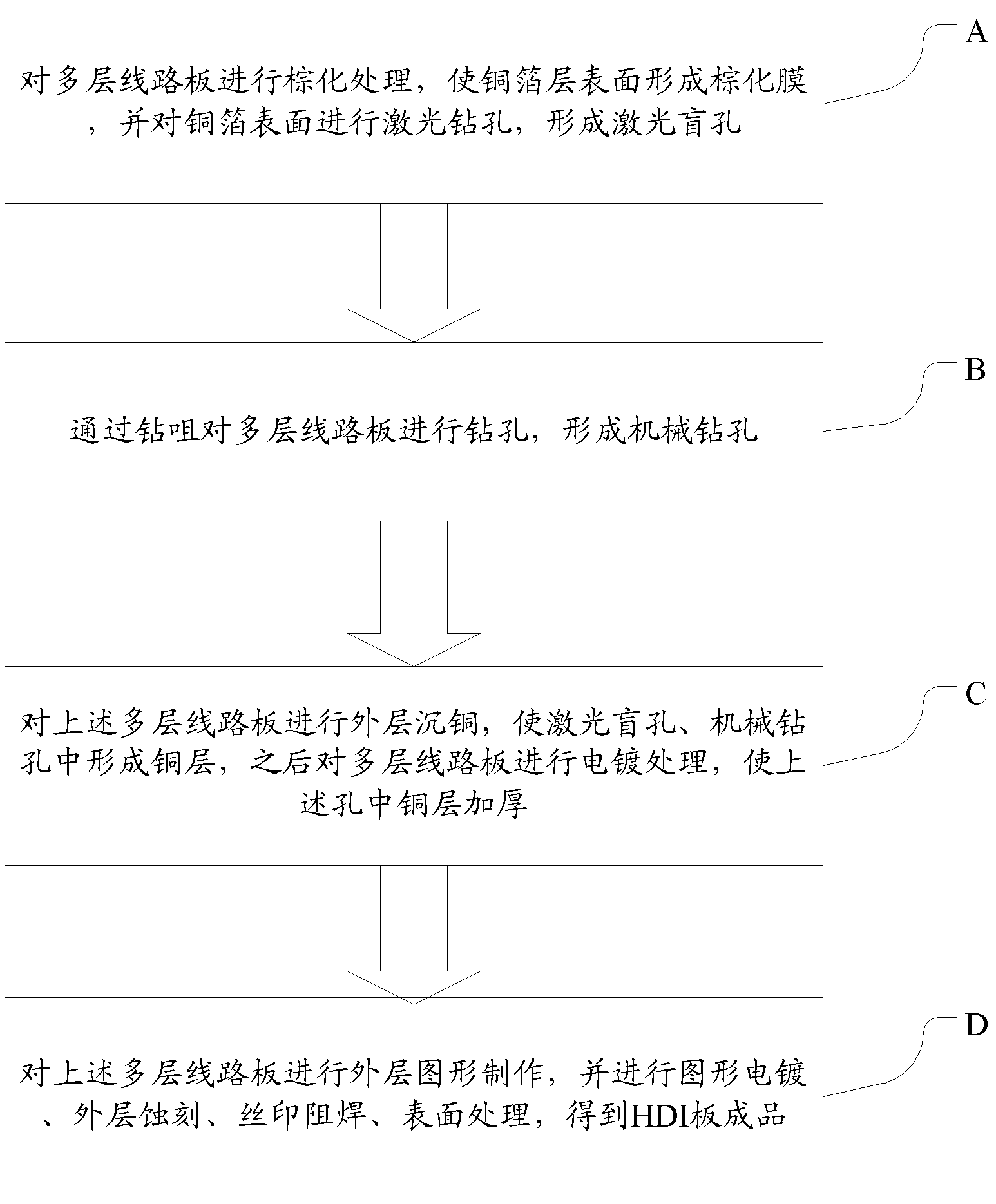

[0023] Such as figure 1 , figure 2 As shown, what the present invention provides is a kind of manufacturing process of HDI plate, comprises steps:

[0024] A. Carry out browning treatment on the multilayer circuit board to form a browning film on the surface of the copper foil layer, and perform laser drilling on the surface of the copper foil to form laser blind holes;

[0025] Wherein before step A includes:

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com